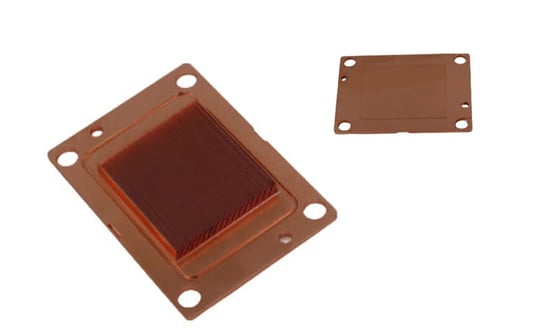

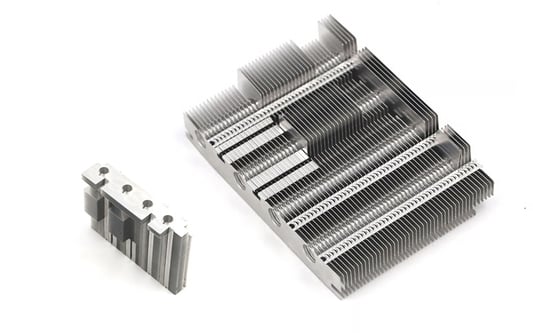

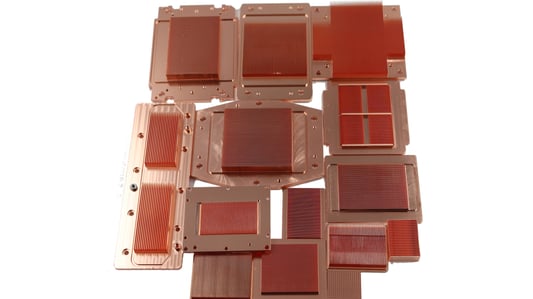

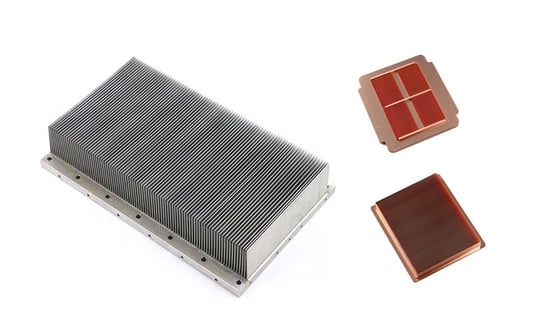

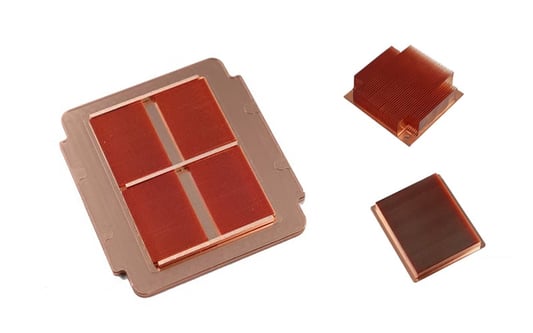

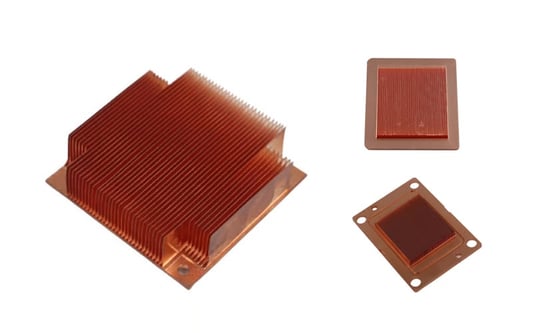

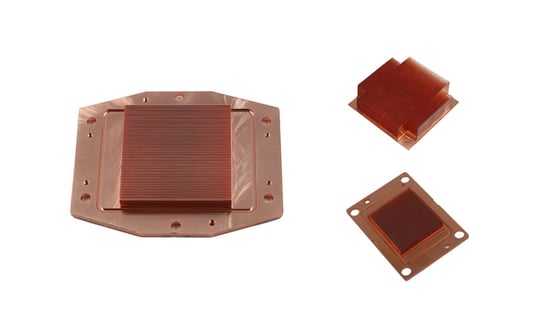

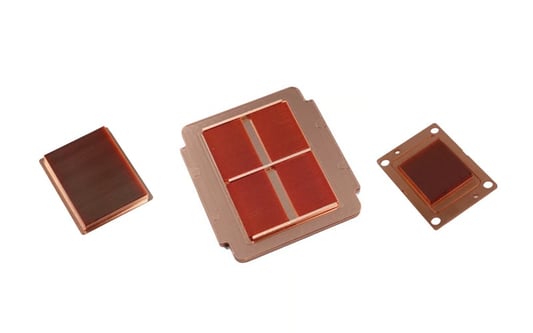

Understanding LED Thermal ManagementLEDs are efficient sources of light, but they also generate a considerable amount of heat during operation. Proper thermal management is essential to maintain the longevity and performance of LEDs. Skived heat sinks are becoming increasingly popular for improving LED thermal management due to their excellent heat dissipation capabilities.How Skived Heat Sinks WorkSkived heat sinks are made by cutting thin slices of metal in a spiral pattern to create a design with increased surface area. This design allows for better heat transfer from the LED to the surrounding environment, ensuring that the temperature stays within safe operating limits. Skived heat sinks are lightweight, cost-effective, and highly efficient at cooling LEDs.The Benefits of Skived Heat SinksSkived heat sinks offer several advantages for LED thermal management. They have a large surface area for enhanced heat dissipation, rapid thermal conductivity, and a compact design that allows for easy integration into LED lighting fixtures. Additionally, skived heat sinks are durable and reliable, making them an ideal choice for demanding applications.Comparing Skived Heat Sinks to Other Cooling SolutionsWhen compared to traditional heat sinks or other cooling methods, skived heat sinks stand out due to their superior efficiency and performance. Traditional heat sinks may be bulky and less effective at dissipating heat, while other cooling solutions such as fans can be noisy and prone to mechanical failure. Skived heat sinks provide a silent and dependable cooling solution for LEDs.Design Considerations for Skived Heat SinksWhen designing LED lighting systems with skived heat sinks, it is essential to consider factors such as the heat output of the LEDs, the airflow around the heat sink, and the thermal conductivity of the materials used. By optimizing the design of the skived heat sink, it is possible to achieve maximum cooling efficiency and extend the lifespan of the LEDs.Installation and Maintenance of Skived Heat SinksProper installation and maintenance of skived heat sinks are crucial to ensure their effectiveness in cooling LEDs. It is important to securely mount the heat sink to the LED and maintain good thermal contact between the two components. Regular cleaning and inspection of the heat sink can help prevent dust buildup and maintain optimal thermal performance.Applications of Skived Heat Sinks in LED LightingSkived heat sinks are widely used in various LED lighting applications, including commercial lighting, automotive lighting, and industrial lighting. They are capable of dissipating heat efficiently in high-power LED fixtures and can help maintain stable operating temperatures for improved performance and reliability. Skived heat sinks are versatile and can be customized to meet the specific requirements of different lighting applications.Efficiency and Energy Savings with Skived Heat SinksBy using skived heat sinks in LED lighting systems, manufacturers can improve energy efficiency and reduce operating costs. The enhanced thermal management provided by skived heat sinks enables LEDs to operate at lower temperatures, increasing their lifespan and reducing the need for frequent replacements. This results in long-term energy savings and a lower environmental impact.Future Developments in LED Thermal ManagementAs LED technology continues to advance, the demand for effective thermal management solutions will also grow. Skived heat sinks are expected to play a key role in meeting this demand, thanks to their proven performance and reliability. Future developments may include the use of advanced materials, innovative designs, and optimized manufacturing processes to further enhance the cooling capabilities of skived heat sinks.ConclusionSkived heat sinks are a versatile and efficient solution for improving LED thermal management. By utilizing skived heat sinks in LED lighting systems, manufacturers can enhance heat dissipation, increase energy efficiency, and prolong the lifespan of LEDs. With their excellent performance and reliability, skived heat sinks are set to become a standard choice for maintaining optimal operating temperatures in LED applications.Quote Inquirycontact us