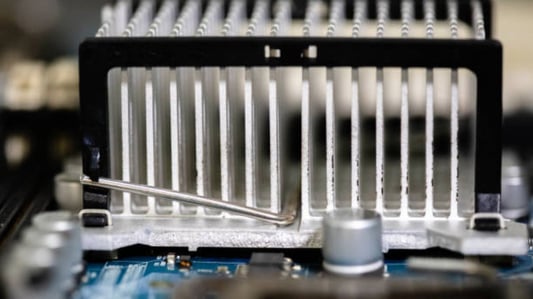

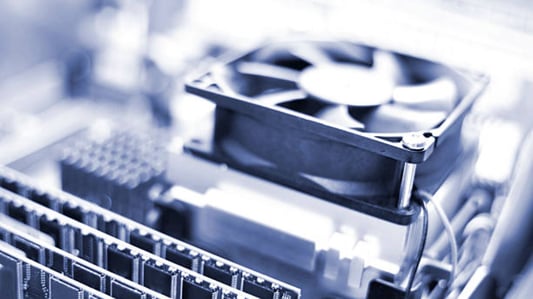

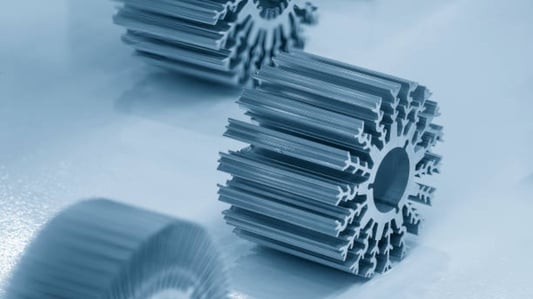

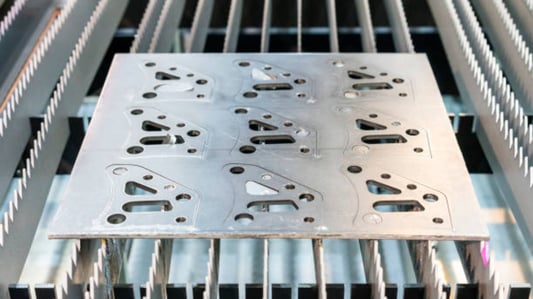

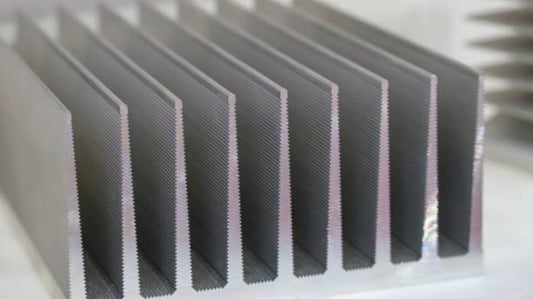

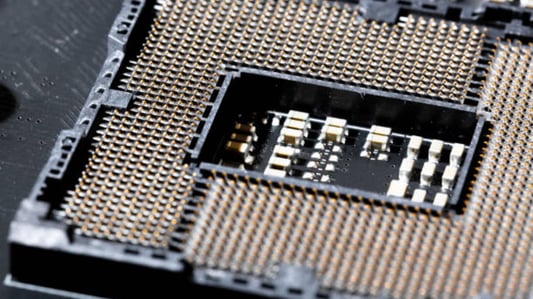

IntroductionA heat sink is an essential component in many electronic devices, as it helps to dissipate heat generated by the device. The efficiency of a heat sink largely depends on the material used to make it. In this article, we will explore some of the most efficient materials for a heat sink.CopperCopper is one of the most widely used materials for heat sinks due to its high thermal conductivity and low cost. Copper heat sinks can efficiently transfer heat from the source to the surrounding environment. They are also easy to manufacture, making them a popular choice for many applications.AluminumAluminum is another commonly used material for heat sinks. It has a lower thermal conductivity than copper, but it is also less expensive and lighter. Aluminum heat sinks are ideal for applications where weight is a concern. They can be anodized to improve their durability and resistance to corrosion.GrapheneGraphene is a relatively new material that has been shown to have excellent thermal conductivity. It is a two-dimensional material made of a single layer of carbon atoms, arranged in a hexagonal lattice. Graphene heat sinks are still in the early stages of development, but they have the potential to be highly efficient and lightweight.DiamondDiamond has the highest thermal conductivity of any known material, making it an ideal material for heat sinks. However, diamond is also very expensive and difficult to manufacture. Diamond heat sinks are typically used in specialized applications where cost is not a concern.CeramicsCeramic materials such as aluminum nitride and silicon carbide have high thermal conductivity and are ideal for use in high-temperature applications. Ceramic heat sinks are also highly resistant to corrosion, making them a popular choice in harsh environments.CompositesComposite materials, such as carbon fibers embedded in a resin matrix, can offer the thermal performance of metals at much lower weight. These materials can be molded into complex shapes and are ideal for use in aerospace and automotive applications where weight is a concern.Liquid metalsLiquid metals such as gallium and indium have very high thermal conductivity and can be used as a heat transfer fluid in heat pipes or as a direct contact cooling solution. However, liquid metals can be expensive and require specialized handling.Phase change materialsPhase change materials (PCMs) are materials that can store and release thermal energy during the phase change process. PCMs can be used to absorb and release heat in order to regulate temperature. They are useful in applications where a constant temperature is necessary and can be an alternative to traditional heat sinks.SaltwaterIn some applications where traditional heat sinks are not practical, saltwater can be used as a cooling solution. Saltwater has a high specific heat, which means it can absorb and release large amounts of thermal energy. However, saltwater can be corrosive and requires an appropriate container and handling.ConclusionIn summary, the choice of material for a heat sink largely depends on the specific application requirements. Copper and aluminum are commonly used materials for general applications, while diamond and graphene offer superior thermal conductivity for specialized applications. Composite materials, ceramics, liquid metals, phase change materials, and even saltwater can be used in specific circumstances.heat sink, efficient material, copper, aluminum, graphene, diamond, ceramics, composites, liquid metals, phase change materials, saltwaterWhat is the most efficient material for a heat sink?? - ExplainedA guide to the most efficient materials for heat sinks, including copper, aluminum, graphene, diamond, ceramics, composites, liquid metals, and phase change materials. Learn about the pros and cons of each material.Quote InquiryContact us!