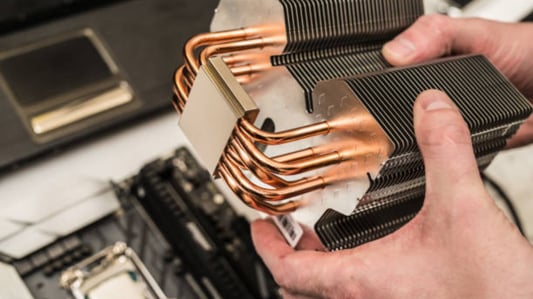

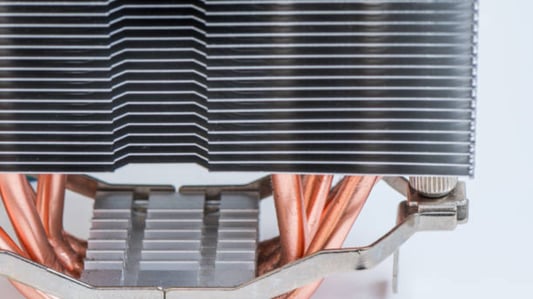

IntroductionAre you struggling with the decision of whether or not to remove the heatsink from your SSD? Fear not, we’ve got you covered. In this article, we’ll be discussing everything you need to know about removing a heatsink from an SSD.What is an SSD Heatsink?An SSD heatsink is essentially a piece of metal that sits on top of your solid-state drive, which helps to dissipate heat. It is commonly used in high-performance PC builds because it can help to improve the overall lifespan of your SSD by keeping its temperature down.Can you remove a heatsink from SSD??Yes, you can remove a heatsink from an SSD. However, it’s important to keep in mind that you should only do this if you have a good reason to. Removing the heatsink could potentially void your warranty and could lead to your SSD overheating, which could result in performance issues.Why Would You Want to Remove an SSD Heatsink?There are a few reasons why you might want to remove the heatsink from your SSD. For example, you might want to remove it to install a new one that fits better with the rest of your PC build. Alternatively, you might need to remove it if you want to install your SSD into a different PC.How Do You Remove an SSD Heatsink?To remove an SSD heatsink, you’ll need to remove the screws that are holding it in place on top of your SSD. Once the screws have been removed, you should be able to lift the heatsink off of your SSD. However, it’s important to be cautious when doing this, as you don’t want to damage your SSD in the process.What Precautions Should You Take Before Removing an SSD Heatsink?Before removing an SSD heatsink, it’s important to ensure that your PC is turned off and unplugged from the wall. This will help to prevent any potential electrical damage to your SSD or other components. You should also wear an anti-static wristband to prevent any static electricity from damaging your SSD.What Happens If You Remove an SSD Heatsink?If you remove an SSD heatsink, your SSD will no longer have the added cooling benefit that it provided. This could potentially result in overheating, which could lead to performance issues. Additionally, removing the heatsink could void your warranty if you damage your SSD in the process.Can You Reattach an SSD Heatsink?Yes, you can reattach an SSD heatsink if you have removed it previously. To do this, simply line up the heatsink with the screw holes on top of your SSD and screw it back in place. However, if you have damaged your SSD or heatsink in the process of removal, you may need to purchase a new one.What Are the Pros and Cons of Removing an SSD Heatsink?One potential benefit of removing an SSD heatsink is that it can allow you to customize your PC more easily. Additionally, if your heatsink was damaged, removing it could be the only way to salvage your SSD. However, removing the heatsink could potentially void your warranty and could lead to overheating issues.ConclusionSo, can you remove a heatsink from SSD? Yes, you can. However, it’s important to carefully consider your reasons for doing so, as well as to take the necessary precautions to prevent damage to your SSD or other PC components. Overall, if you don’t have a good reason to remove the heatsink, it’s probably best to leave it in place to avoid any potential issues.