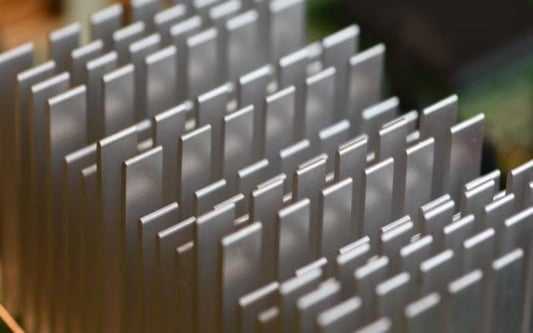

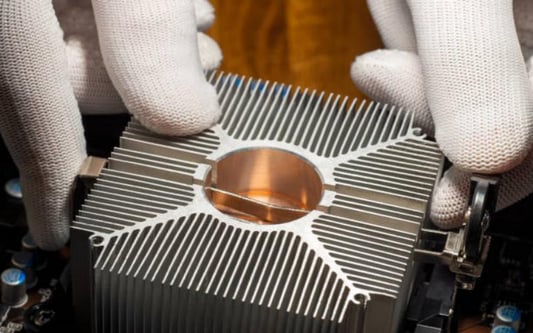

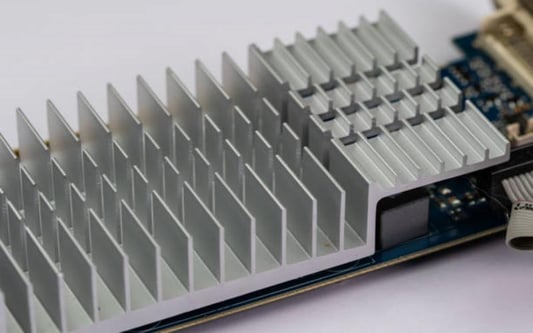

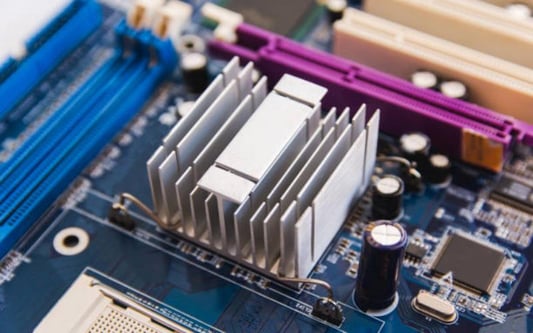

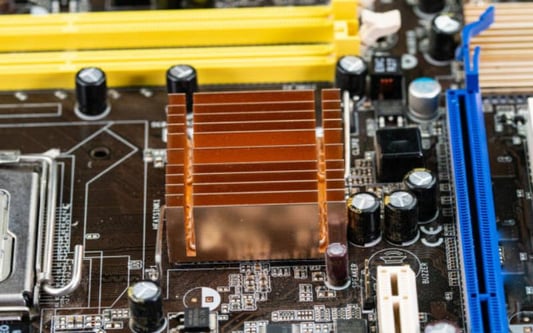

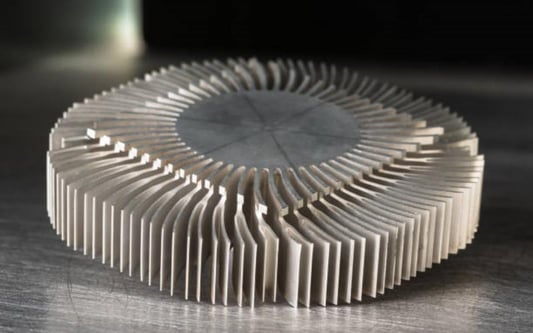

IntroductionHeat sink cooling design plays a crucial role in improving the performance, efficiency, and reliability of Insulated Gate Bipolar Transistors (IGBTs). IGBTs are widely used in various applications, including power electronics, motor drives, renewable energy systems, and electric vehicles. In this article, we will explore the different aspects of IGBT Heat Sink Cooling Design and how it impacts the overall system.1. Understanding IGBT Heat DissipationIGBTs generate heat during operation due to the switching and conduction losses. Heat dissipation is essential to prevent the IGBTs from exceeding their temperature limits, which could result in decreased efficiency and reliability. The heat generated must be efficiently transferred away from the device to maintain optimal operating conditions.2. Importance of Heat Sink in CoolingA heat sink is a passive cooling device that helps dissipate heat from the IGBTs to the surrounding environment. It provides a large surface area to enhance heat transfer through conduction, convection, and radiation. A well-designed heat sink can significantly improve the thermal performance and reliability of IGBTs.3. Choosing the Right Heat SinkWhen selecting a heat sink for IGBT cooling, several factors need to be considered. These include the power dissipation of the IGBT, thermal resistance of the heat sink, available space, airflow conditions, and the desired temperature rise. It is essential to choose a heat sink with the appropriate thermal resistance and surface area to handle the dissipated heat effectively.4. Optimizing Heat Sink DesignOptimizing the heat sink design involves considering various parameters such as fin geometry, base thickness, material selection, and surface treatment. Increasing the surface area of the heat sink fins can improve heat dissipation. Additionally, using materials with high thermal conductivity, such as aluminum or copper, can enhance thermal performance.5. Enhancing Airflow for CoolingAdequate airflow is crucial for effective heat sink cooling. One way to enhance airflow is by using fans or blowers to create forced convection. The heat sink should be positioned in a way that allows maximum air circulation around it. Proper ventilation and ducting can also contribute to better cooling performance.6. Thermal Interface Materials (TIMs)Thermal interface materials, such as thermal grease or pads, are used to improve the thermal contact between the IGBT and the heat sink. These materials fill in the microscopic air gaps and irregularities, reducing thermal resistance and improving heat transfer. Selecting the right TIM and applying it correctly is essential for optimal cooling.7. Heat Sink Mounting ConsiderationsThe mounting method and pressure applied to the heat sink can significantly impact its thermal performance. Proper mounting techniques, such as using screws or clips, ensure good contact between the IGBT and the heat sink. It is crucial to follow manufacturer guidelines and specifications for mounting to avoid any thermal issues.8. Thermal Management SystemIntegrating a comprehensive thermal management system is essential for efficient IGBT heat sink cooling. This system may include temperature sensors, heat sinks, fans, heat pipes, and control algorithms. Monitoring and controlling the temperature of the IGBTs and adjusting the cooling mechanisms accordingly can prevent overheating and ensure optimal performance.9. Challenges in IGBT Heat Sink CoolingDesigning an effective heat sink cooling system for IGBTs poses some challenges. These include limited space availability, high power densities, varying operating conditions, and controlling temperature gradients. Overcoming these challenges requires careful consideration of thermal design, material selection, and system integration.10. Future Trends in IGBT Heat Sink Cooling DesignThe field of IGBT heat sink cooling design continues to evolve, driven by the increasing demand for more efficient and reliable power electronics systems. Some future trends include the use of advanced materials like graphene for improved thermal conductivity, innovative heat sink designs with microchannels for enhanced cooling, and the integration of intelligent cooling systems using artificial intelligence and machine learning algorithms.Quote Inquiry