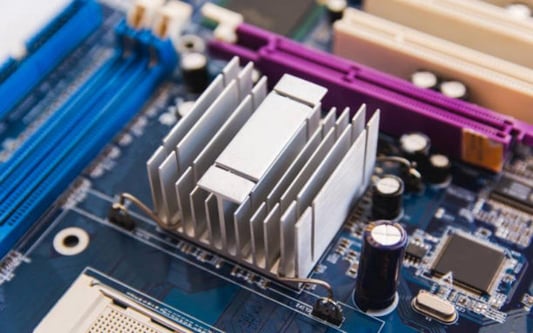

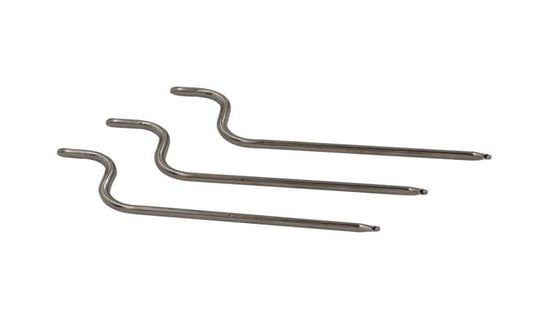

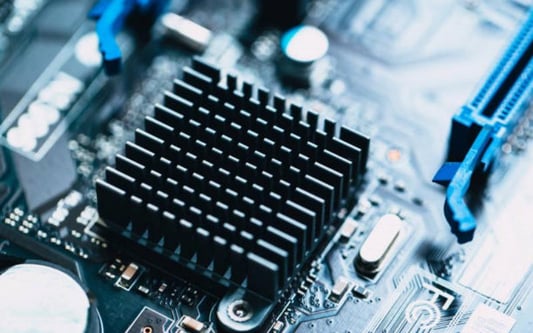

The Various Applications of Cold ForgingCold forging is a manufacturing process that involves shaping metal parts at room temperature using compressive forces. This process offers numerous advantages over traditional machining techniques, including improved material strength, cost-effectiveness, and enhanced production efficiency. In this article, we will explore the diverse applications of cold forging across different industries.1. Automotive IndustryCold forging finds extensive use in the automotive industry due to its ability to produce high-strength and lightweight components. Applications include the production of gears, shafts, ball joints, and steering system parts. Cold forged parts offer improved durability, higher precision, and reduced material waste, making them ideal for enhancing the overall performance and safety of vehicles.2. Aerospace IndustryIn the aerospace industry, where safety and reliability are paramount, cold forging plays a crucial role. It is used to manufacture critical components like landing gear, turbine blades, engine parts, and fasteners. Cold forged aerospace parts exhibit excellent fatigue resistance, dimensional accuracy, and structural integrity, ensuring the utmost reliability in demanding conditions.3. Construction IndustryCold forging is widely employed in the construction industry for producing durable and corrosion-resistant fasteners, bolts, screws, and anchors. These cold forged fasteners offer superior performance in terms of load-bearing capacity, resistance to shear forces, and optimized structural integrity. Their high strength and reliability make them indispensable for construction projects of all scales.4. Electronics IndustryThe electronics industry benefits from cold forging in the production of connectors, terminals, pins, and other electronic components. Cold forging allows for precise shaping of intricate designs, ensuring optimal conductivity, excellent mechanical properties, and reliable electrical connections. The high production efficiency and cost-effectiveness of cold forging make it a preferred choice for mass production in the electronics sector.5. Medical IndustryCold forging plays a crucial role in the medical industry, particularly in the manufacturing of surgical instruments, orthopedic implants, and dental tools. Cold forged medical devices offer superior biocompatibility, corrosion resistance, and precise dimensions. The process ensures the production of high-quality, sterile, and safe medical equipment that meets stringent industry standards.6. Energy SectorIn the energy sector, cold forging is widely used for producing components for power transmission and distribution systems. Cold forged parts such as electrical connectors, terminals, and busbars exhibit excellent electrical conductivity, heat dissipation, and mechanical strength. These parts are essential for ensuring efficient and reliable energy transmission, contributing to enhanced overall system performance.7. Agricultural MachineryCold forging finds applications in the manufacturing of agricultural machinery components like gears, shafts, and blades. These components require high strength, wear resistance, and durability to withstand the demanding conditions of agricultural operations. Cold forging ensures the production of robust and long-lasting parts that contribute to the efficiency and productivity of agricultural machinery.8. Defense and Military ApplicationsCold forging is extensively utilized in defense and military applications due to its ability to produce highly durable and reliable components. It is used in the manufacturing of firearms, artillery, munitions, and various equipment parts. Cold forged military components offer superior strength, precision, and dimensional stability, ensuring optimal performance and safety in critical operations.9. General Industrial ApplicationsCold forging is also employed in general industrial applications, including the production of hand tools, hardware, industrial machinery components, and consumer goods. The process allows for the efficient production of high-quality parts with excellent mechanical properties, enabling the manufacturing industry to meet diverse demands effectively.10. Green Energy SectorIn the emerging green energy sector, cold forging plays a vital role in the manufacturing of wind turbine components, solar panel frames, and other renewable energy equipment. Cold forged parts offer exceptional strength, durability, and resistance to environmental factors, ensuring the reliable and long-term operation of green energy systems.cold forging applications, automotive industry, aerospace industry, construction industry, electronics industry, medical industry, energy sector, agricultural machinery, defense applications, general industrial applications, green energy sector What Are The Cold Forging Applications?? Exploring Diverse Industries Discover the various applications of cold forging in industries such as automotive, aerospace, construction, electronics, medical, energy, and more. Enhance your understanding of this versatile manufacturing process.Quote InquiryFooter