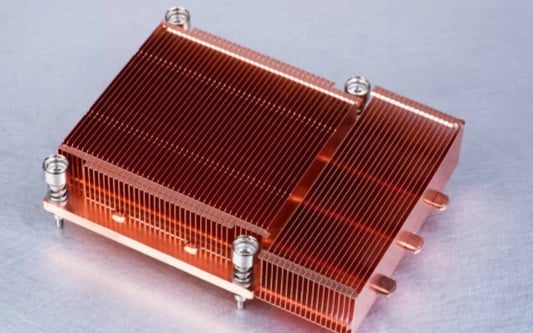

IntroductionAluminum Nitride (AlN) has been recognized as a potential material for heat sink applications because of its excellent thermal conductivity, high electrical insulation, and good mechanical strength. AlN heat sinks offer promising solutions for thermal management in electronics as they provide efficient heat dissipation and protect semiconductor devices from overheating damage.What is Aluminum Nitride?Aluminum Nitride is a ceramic material that possesses unique properties, including high thermal conductivity, low dielectric loss, and high breakdown voltage. It is a synthetic compound of aluminum and nitrogen with a hexagonal crystal structure. The material is lightweight and has a thermal conductivity of up to 200 W/mK, which is higher than that of most metals used as heat sinks.How Does aluminum nitride heat sink Work?Aluminum Nitride heat sink works by transferring heat away from the source to the surrounding environment. The heat generated by electronic components is conducted through the metal substrate and into the AlN layer, which then dissipates it into the ambient air. The high thermal conductivity of AlN allows the heat to spread uniformly throughout the heat sink, leading to efficient cooling of electronic devices.Advantages of Aluminum Nitride Heat SinkAluminum Nitride heat sinks offer several advantages over other conventional materials used for heat sinks, such as copper or aluminum. The significant advantages of AlN heat sinks include:High Thermal Conductivity: Aluminum Nitride has a high thermal conductivity of up to 200 W/mK, which is higher than most metals used as heat sinks.Electrical Insulation: AlN is an electrical insulator, which helps in preventing short circuits between adjacent electronic components.Chemical Stability: AlN is chemically stable, which means it does not corrode or react with most chemicals, making it suitable for a wide range of applications.Mechanical Strength: AlN has good mechanical strength and can withstand high temperatures, making it an ideal material for high power electronic devices.Applications of Aluminum Nitride Heat SinkAluminum Nitride heat sinks are primarily used in high-power electronic devices, such as power amplifiers, power modules, and high-power LEDs. Some of the common applications of AlN heat sinks include:Power Amplifiers: High-power amplifiers require efficient cooling to prevent thermal breakdown. AlN heat sink provides an effective solution for dissipating heat generated by these devices.Power Modules: Aluminum Nitride heat sinks are commonly used in power modules that convert energy from one form to another. These modules produce a significant amount of heat that needs to be dissipated efficiently to ensure reliable performance.High-Power LEDs: AlN heat sinks are suitable for high-power LED applications due to their high thermal conductivity and excellent heat dissipation properties. They help in extending the lifespan of the LED and maintaining optimal performance.Types of Aluminum Nitride Heat SinkThere are two main types of Aluminum Nitride heat sinks: Ceramic and Metal-Clad. Ceramic AlN heat sinks are made entirely of AlN material, whereas Metal-Clad AlN heat sinks have an AlN layer sandwiched between a metal substrate and a solderable layer.Fabrication of Aluminum Nitride Heat SinkAluminum Nitride heat sinks can be fabricated using several techniques, including hot pressing, hot isostatic pressing, and tape casting. The fabrication process involves forming the AlN powder into a green body, which is then sintered at high temperatures to form a dense and uniform material.ConclusionAluminum Nitride heat sinks offer a promising solution for thermal management in high-power electronic devices. The high thermal conductivity, electrical insulation, and good mechanical strength properties of AlN make it an ideal material for heat sink applications. With the increasing demand for high-power electronics, the use of Aluminum Nitride heat sinks is expected to grow in the future.Aluminum Nitride Heat Sink, AlN, High Thermal Conductivity, Electrical Insulation, Chemical Stability, Mechanical Strength, Power Amplifiers, Power Modules, High-Power LEDs, Ceramic AlN Heat Sink, Metal-Clad AlN Heat Sink, FabricationAluminum Nitride Heat Sink: A Promising Solution for Thermal ManagementLearn about the properties, advantages, applications, types and fabrication of Aluminum Nitride Heat Sink - a promising solution for heat dissipation in high-power electronic devices. - What are the advantages of Aluminum Nitride Heat Sink for Power Amplifiers?- How does Aluminum Nitride Heat Sink work in High-Power LEDs?- Understanding the Fabrication Process of Ceramic AlN Heat Sink- Comparison between Ceramic AlN Heat Sink and Metal-Clad AlN Heat Sink - Why is Aluminum Nitride Heat Sink preferred for Thermal Management?Quote InquiryContact us!