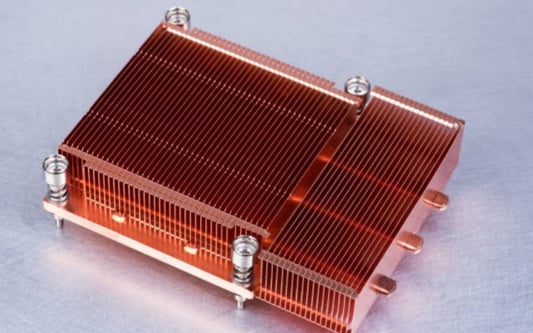

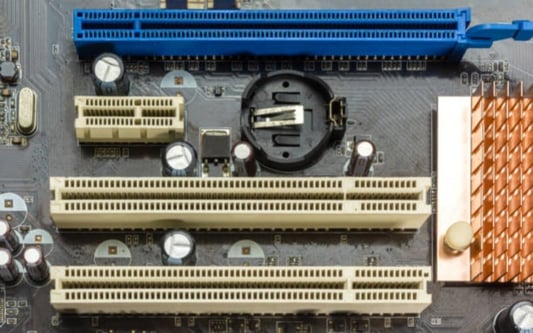

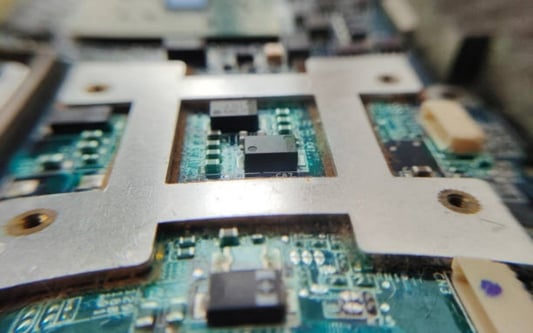

The Importance of Heat Sinks in Electronic DevicesIn today's technologically advanced world, electronic devices are becoming increasingly powerful and compact. However, this progress also brings along the challenge of managing heat generated by these devices. Excessive heat can lead to performance degradation, shortened lifespan, and even catastrophic failure. This is where heat sinks play a crucial role. In this article, we will explore the advantages and disadvantages of heat sinks, shedding light on their significance in electronic devices.Advantage 1: Efficient Heat DissipationOne of the primary advantages of a heat sink is its ability to efficiently dissipate heat. When electronic components, such as processors and power transistors, operate, they generate heat. The heat sink, typically made of metal, acts as a passive cooling system that absorbs and spreads the heat away from the component's surface. This process ensures that the temperature of the electronic device remains within acceptable limits.Advantage 2: Increased Lifespan of ComponentsBy effectively reducing the temperature of electronic components, heat sinks contribute to their longevity. High temperatures can accelerate the aging process and cause premature failure of sensitive electronic parts. Heat sinks help maintain optimal operating temperatures, thereby extending the lifespan of the components they are attached to.Advantage 3: Noise ReductionSome electronic devices, such as computers and gaming consoles, have cooling fans to regulate temperature. However, these fans can create noise that can be distracting or irritating. Heat sinks offer a silent cooling solution by efficiently dissipating heat without the need for fans. This advantage is particularly valuable in noise-sensitive environments, such as recording studios or offices.Advantage 4: Compact DesignHeat sinks are designed to be compact, allowing them to be integrated into various electronic devices without occupying excessive space. Their small form factor enables manufacturers to create sleek and slim devices, such as laptops and smartphones, while still ensuring optimal thermal management.Advantage 5: Cost-Effective SolutionCompared to active cooling methods, such as liquid cooling or thermoelectric coolers, heat sinks offer a cost-effective solution. They are relatively inexpensive to produce, require no additional power source, and have no moving parts that could wear out or fail. This affordability makes heat sinks an attractive choice for a wide range of electronic devices.Disadvantage 1: Limited Cooling CapacityWhile heat sinks are effective in dissipating heat, they have a limited cooling capacity. This means that if the electronic device generates excessive heat or operates in extreme environments, a heat sink alone may not be sufficient to keep temperatures within safe limits. In such cases, additional cooling methods, such as fans or liquid cooling, may be required.Disadvantage 2: Inefficient in Low-Airflow EnvironmentsHeat sinks rely on airflow to efficiently dissipate heat. In environments with minimal or stagnant airflow, such as inside sealed enclosures or densely packed electronic devices, heat sinks may struggle to perform optimally. In these situations, alternative cooling methods may need to be considered.Disadvantage 3: Size and Weight RestrictionsWhile heat sinks are generally compact, there are instances where size and weight restrictions pose challenges. In certain applications, such as aerospace or automotive electronics, space is limited, and every gram counts. Heat sinks, along with their mounting systems, may need to be carefully designed to meet these constraints without compromising performance.Disadvantage 4: Compatibility IssuesHeat sinks are designed to be compatible with specific electronic components or devices. However, as technology advances and new devices are introduced, compatibility issues may arise. Ensuring the right heat sink for a particular device can be a challenge, especially when dealing with older or niche products. This can limit the options available for replacing or upgrading heat sinks.Disadvantage 5: Aesthetics and Design ConstraintsHeat sinks, although necessary for efficient cooling, may not always align with the desired aesthetics or design of electronic devices. In consumer electronics, where appearance plays a significant role, heat sinks may need to be concealed or integrated seamlessly into the overall design. Balancing functionality and aesthetics can be a delicate process.Quote InquiryContact us!