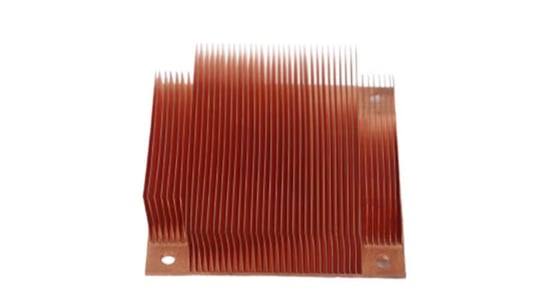

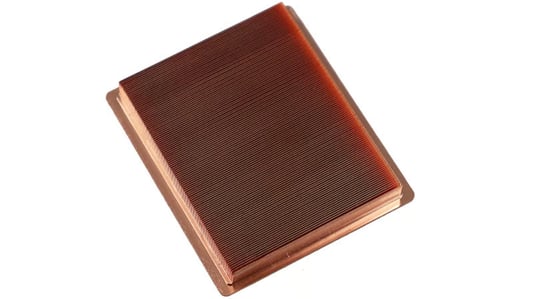

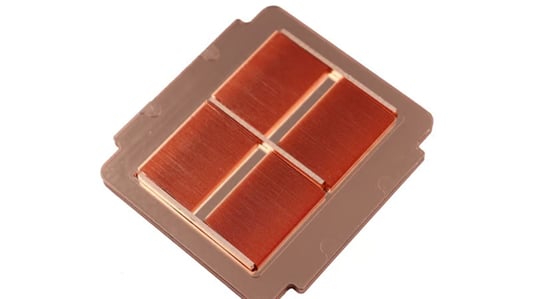

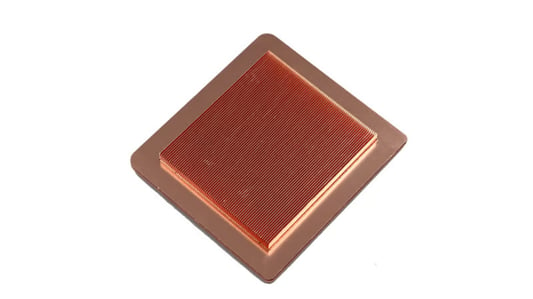

Aluminum Aluminum is one of the most common materials used for CPU heat sinks due to its excellent thermal conductivity and lightweight properties. This metal is widely available and cost-effective, making it a popular choice for manufacturers. The high thermal conductivity of aluminum allows for efficient heat dissipation, which is essential for keeping the CPU cool during operation. Additionally, its lightweight nature helps to reduce the overall weight of the heat sink, making it easier to install and handle.Copper Copper is another common material used for CPU heat sinks, known for its superior thermal conductivity compared to aluminum. While copper is heavier and more expensive than aluminum, its ability to transfer heat quickly and efficiently makes it a popular choice for high-performance computing systems. The use of copper heat sinks can result in better heat dissipation and improved overall cooling performance for the CPU.Effectiveness in Heat Dissipation When comparing aluminum and copper heat sinks, it is essential to consider their effectiveness in dissipating heat from the CPU. Copper has a higher thermal conductivity than aluminum, allowing it to transfer heat more effectively and efficiently. This means that copper heat sinks can provide better cooling performance compared to aluminum heat sinks, especially in situations where the CPU generates a significant amount of heat.Cost Considerations Cost is an important factor to consider when choosing between aluminum and copper heat sinks for a CPU. Aluminum heat sinks are generally more affordable than copper heat sinks, making them a popular choice for budget-friendly builds. However, if performance is a top priority and budget is not a concern, copper heat sinks may be the preferred option due to their superior thermal conductivity and heat dissipation capabilities.Compatibility with CPUs Both aluminum and copper heat sinks are compatible with a wide range of CPUs, making them versatile options for cooling systems. When selecting a heat sink for a specific CPU, it is crucial to consider factors such as size, shape, and mounting mechanism to ensure proper compatibility. Manufacturers often provide compatibility information for their heat sinks, helping consumers make informed decisions based on their specific CPU requirements.Heat Sink Design The design of a heat sink can also impact its effectiveness in dissipating heat from the CPU. Factors such as fin density, surface area, and fan placement play a role in determining the overall cooling performance of the heat sink. Some heat sinks feature heat pipes or vapor chambers to further enhance heat dissipation. When choosing between aluminum and copper heat sinks, consider the design elements that best suit the cooling needs of your CPU.Overclocking Performance For users seeking to overclock their CPUs for increased performance, the choice of heat sink material can have a significant impact on cooling efficiency. Copper heat sinks are often favored by overclockers due to their superior thermal conductivity, which allows for more effective heat dissipation during heavy workloads. While aluminum heat sinks can still provide adequate cooling for overclocked CPUs, copper heat sinks are generally preferred for extreme performance scenarios.Environmental Considerations When selecting a CPU heat sink material, it is important to consider the environmental impact of the chosen material. Aluminum is a highly recyclable metal, making it a more environmentally friendly option compared to copper. While copper is also recyclable, its extraction and processing can have a greater environmental impact. By choosing aluminum heat sinks, users can contribute to sustainable practices and reduce their carbon footprint.Durability and Longevity In addition to thermal conductivity and cooling performance, durability and longevity are essential factors to consider when choosing a CPU heat sink material. Copper heat sinks are known for their durability and resistance to corrosion, making them a long-lasting cooling solution for high-performance systems. While aluminum heat sinks are generally less durable than copper, they can still provide reliable cooling performance for many years with proper maintenance and care.Conclusion In conclusion, aluminum and copper are the two most common materials used for CPU heat sinks, each offering unique advantages and considerations. Aluminum heat sinks are cost-effective and lightweight, making them a popular choice for budget builds. Copper heat sinks, on the other hand, offer superior thermal conductivity and cooling performance, ideal for high-performance computing systems. When selecting a CPU heat sink, consider factors such as cost, compatibility, performance, and environmental impact to choose the best material for your cooling needs.Quote InquiryContact us!

20. March, 2025