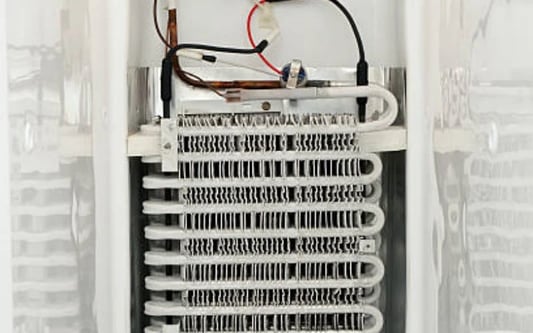

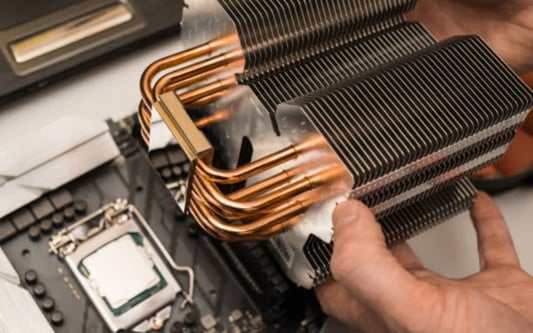

Introductionled heat sink modules are an essential part of LED lighting systems. They play a crucial role in optimized LED performance and prolonging their lifespan. In this article, we will discuss everything you need to know about LED heat sink modules.What is an LED Heat Sink Module?LED heat sink modules are heat-dissipating components that work to lower the operating temperature of LEDs. They are designed to dissipate the heat generated by the LED, which, if uncontrolled, can reduce the efficiency and lifespan of the LED. The heat sink module ensures that LEDs operate at maximum efficiency and are protected from damage due to high temperatures.How Do LED Heat Sink Modules Work?LED heat sink modules work by transferring heat away from the LED source to the surrounding environment. The heat sink module is designed with fins or other structures that increase the surface area exposed to the environment, thereby increasing the heat dissipation level. The design of the heat sink module is crucial because it determines the thermal resistance and heat transfer performance of the device.Types of LED Heat Sink ModulesThere are several types of LED heat sink modules to choose from, each designed to meet specific requirements. These include standard extruded heat sinks, folded-fin heat sinks, and heat pipes. Other unique designs for LED heat sink modules include die-cast heat sinks, bonded fin heat sinks, and zipper fin heat sinks.Choosing the Right LED Heat Sink ModuleChoosing the right LED heat sink module is critical since the wrong design can lead to thermal failure and reduced LED performance. The ideal heat sink module should provide adequate thermal performance, aesthetics, and compatibility with the LED lighting fixture. For instance, heat sink modules designed for small form factors may not provide sufficient thermal efficiency for high-powered LEDs.The Importance of Thermal Management in LED Lighting SystemsThermal management is a vital aspect of LED lighting systems. The LED operates at a high temperature, which, if not controlled, can lead to a reduced lifespan. Moreover, the LED's efficiency can decrease as the operating temperature increases. Adequate thermal management ensures that LEDs operate at maximum efficiency, reducing the need for maintenance and improving product reliability.What to Look for in an LED Heat Sink ModuleWhen purchasing an LED heat sink module, ensure that it has all the necessary features to provide optimum LED performance. These include thermal performance, efficient heat distribution, and mechanical compatibility. The heat transfer coefficient, the thermal resistance, and the material used are key factors to consider when selecting an LED heat sink module.Cooling Fans vs. Heat Sink Modules: Which is Better?Cooling fans and heat sink modules are both effective thermal management solutions for LED lighting systems. Cooling fans are ideal for cooling high-powered LEDs, while heat sink modules are more efficient at dissipating heat from the LED source. A combination of both cooling fans and heat sink modules may provide optimal thermal management since they complement each other.The Hazards of Overheating LEDsOverheating can result in catastrophic failure of the LED, ultimately leading to expensive repairs and replacements. Overheating can also cause color distortion and reduced brightness levels. Regular maintenance and adequate thermal management can help prevent the LED from overheating and prolong its lifespan.The Future of LED Heat Sink ModulesThe future of LED heat sink modules is likely to focus on enhancing thermal performance and efficiency. Advances in technology are likely to result in more advanced designs that provide better thermal management and dissipate heat more effectively. The use of advanced thermal materials and the addition of thermal interface materials are likely to enhance the performance of LED heat sink modules in the future.ConclusionLED heat sink modules are an essential component of LED lighting systems, primarily used for thermal management. The right heat sink module can ensure optimal LED performance, prolong the lifespan of LEDs, and reduce maintenance costs. Remember to look for key features such as thermal performance and heat transfer coefficients when selecting an LED heat sink module. Adequate thermal management ensures that LEDs operate at maximum efficiency, reducing the need for maintenance and improving product reliability.Quote InquiryContact us!