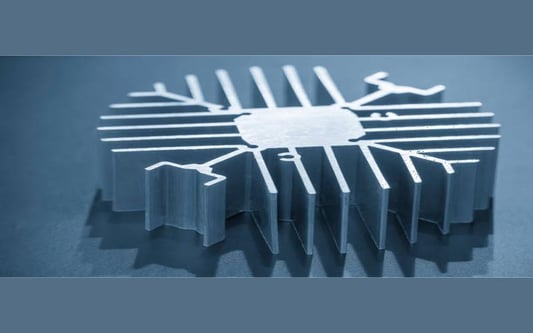

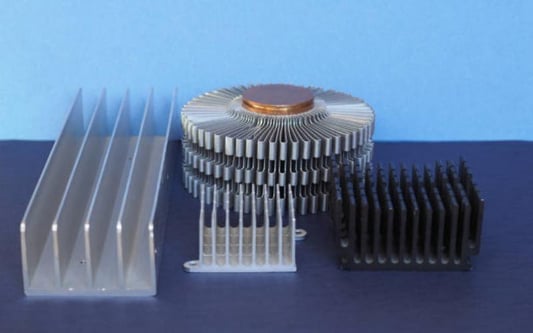

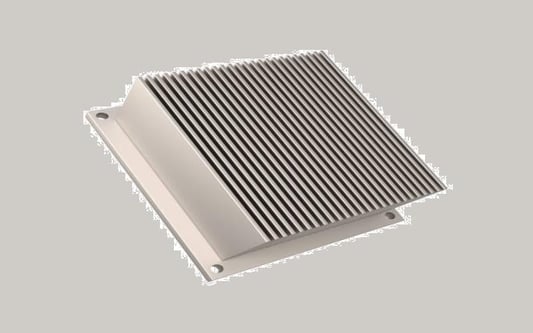

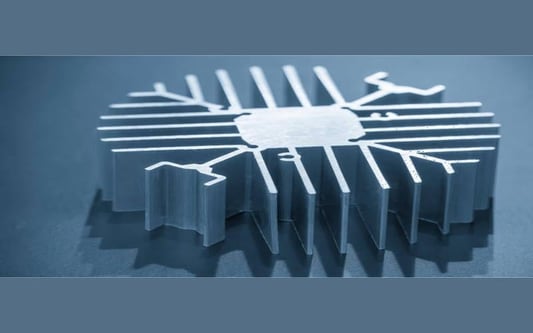

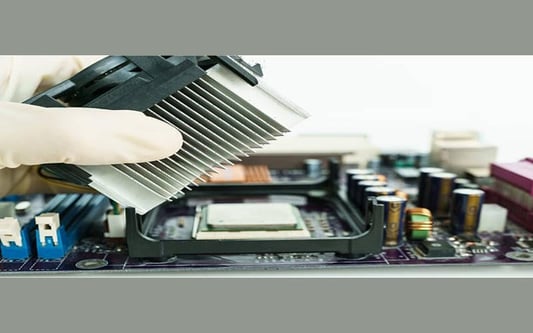

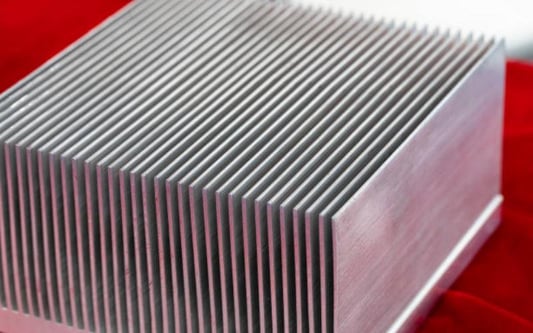

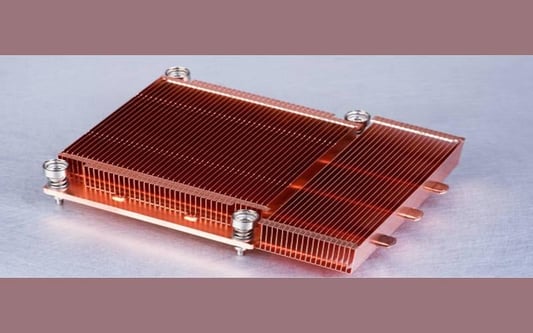

1. Introduction to Extruded AluminumExtruded aluminum is a versatile material that finds its applications in various industries. It is created by forcing aluminum through a die to create complex cross-sectional shapes. This process allows for the creation of lightweight, durable, and corrosion-resistant aluminum profiles. The applications of extruded aluminum are vast and can be found in sectors such as construction, transportation, electronics, and more.2. Construction IndustryIn the construction industry, extruded aluminum is widely used for its strength, versatility, and aesthetic appeal. It is commonly used for the framing of windows, doors, curtain walls, and skylights. The lightweight nature of extruded aluminum makes it easier to handle and install, reducing labor costs. Additionally, its corrosion resistance ensures longevity even in harsh weather conditions.3. Automotive SectorExtruded aluminum plays a vital role in the automotive industry due to its lightweight and high strength-to-weight ratio. It is used in the construction of car frames, chassis components, and engine parts. The reduced weight of extruded aluminum helps improve fuel efficiency and overall vehicle performance. Moreover, its excellent thermal conductivity makes it ideal for heat dissipation in radiators and heat exchangers.4. Electrical and ElectronicsThe electrical and electronics industry benefits greatly from the use of extruded aluminum. It is commonly utilized in the production of heat sinks, LED lighting fixtures, and electronic enclosures. The excellent thermal properties of extruded aluminum help dissipate heat efficiently, ensuring the longevity and reliability of electronic components.5. Aerospace Applications of Extruded AluminumExtruded aluminum is extensively used in the aerospace industry due to its lightweight nature and high strength. It finds its applications in aircraft frames, wing structures, and interior components. The corrosion resistance of extruded aluminum is crucial in ensuring the safety and durability of aircraft, especially in challenging environments.6. Furniture ManufacturingThe furniture industry benefits from the versatility and aesthetic appeal of extruded aluminum. It is commonly used in the production of outdoor furniture, such as patio sets and garden chairs. The lightweight nature of extruded aluminum makes it easy to move and rearrange furniture pieces, while its corrosion resistance ensures longevity even in outdoor environments.7. Marine Applications of Extruded AluminumExtruded aluminum plays a significant role in the marine industry, where corrosion resistance is of utmost importance. It is used in the construction of boat frames, hulls, and various marine components. The lightweight nature of extruded aluminum helps improve fuel efficiency and overall performance, while its resistance to rust and corrosion ensures longevity in saltwater environments.8. Renewable Energy SectorThe renewable energy sector benefits from the use of extruded aluminum in solar panel frames and mounting systems. The lightweight and corrosion-resistant properties of extruded aluminum make it an ideal material for supporting solar panels while withstanding outdoor conditions. Additionally, its recyclability aligns with the sustainability goals of the renewable energy industry.9. Industrial EquipmentExtruded aluminum is widely used in the manufacturing of industrial equipment and machinery. It is utilized for the construction of frames, enclosures, and structural components. The lightweight nature of extruded aluminum helps reduce the overall weight of equipment, making it easier to transport and install. Its durability and corrosion resistance ensure long-term reliability in industrial settings.10. Consumer GoodsExtruded aluminum finds its applications in various consumer goods, including kitchen appliances, sporting equipment, and home decor items. It is valued for its lightweight nature, durability, and modern aesthetic appeal. Extruded aluminum is often used in the production of cookware, bicycles, picture frames, and more.Quote Inquiry