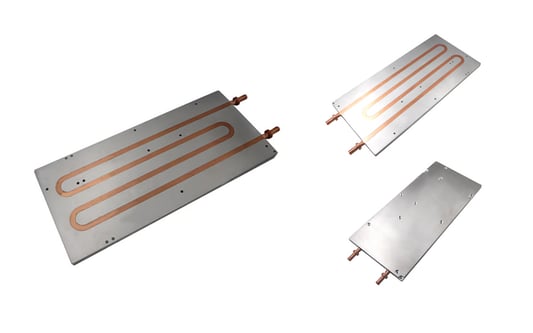

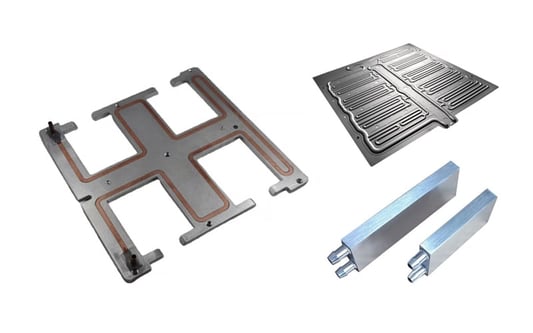

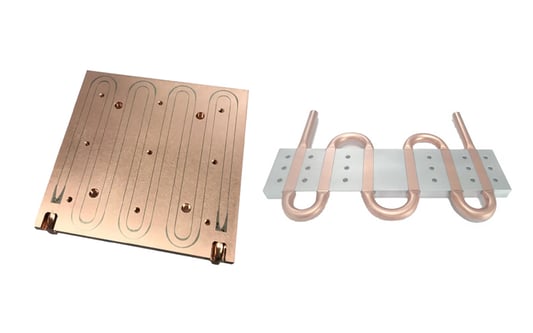

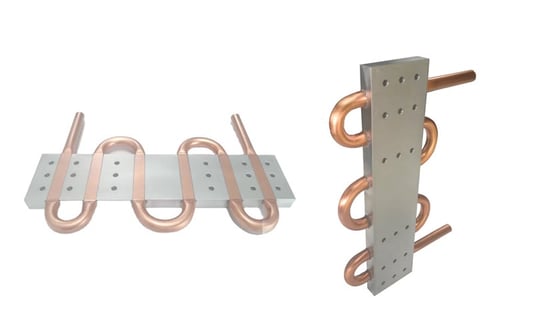

Benefits of Liquid Cold Plate PrototypingLiquid cold plate prototyping offers numerous benefits such as efficient heat dissipation, lightweight design, and customizable configurations. These plates are especially useful for industries requiring precise temperature control and thermal management solutions.Cost Savings with Liquid Cold Plate PrototypingCompared to traditional cooling methods, liquid cold plate prototyping can result in significant cost savings in the long run. These plates are highly durable and require minimal maintenance, reducing overall operating costs for businesses.Customization Options for Liquid Cold Plate PrototypingOne of the key advantages of liquid cold plate prototyping is the ability to customize the design to meet specific requirements. Manufacturers can tailor the size, shape, and material of the plates to suit the unique needs of their applications.Efficiency of Liquid Cold Plate PrototypingLiquid cold plates are known for their high thermal conductivity, allowing for efficient heat transfer and dissipation. This results in better performance and reliability, making them a preferred choice for industries with stringent cooling requirements.Environmental Benefits of Liquid Cold Plate PrototypingLiquid cold plates are environmentally friendly cooling solutions that help reduce energy consumption and carbon footprint. By implementing these plates, businesses can contribute to sustainability efforts and promote eco-friendly practices.Applications of Liquid Cold Plate PrototypingLiquid cold plates are commonly used in various industries, including automotive, aerospace, and telecommunications. They are ideal for cooling electronics, batteries, lasers, and other heat-sensitive components that require reliable thermal management.Material Selection for Liquid Cold Plate PrototypingWhen choosing materials for liquid cold plate prototyping, factors such as thermal conductivity, corrosion resistance, and cost-effectiveness should be considered. Common materials used include copper, aluminum, and stainless steel, each offering unique benefits for different applications.Testing and Validation of Liquid Cold Plate PrototypesBefore full-scale production, it is crucial to test and validate liquid cold plate prototypes to ensure they meet performance and quality standards. Thorough testing helps identify any potential issues and allows for necessary adjustments to be made.Collaborating with Expert Manufacturers for Liquid Cold Plate PrototypingPartnering with experienced manufacturers specializing in liquid cold plate prototyping can streamline the development process and ensure the production of high-quality plates. These experts can provide valuable insights and guidance throughout the design and manufacturing stages.Future Trends in Liquid Cold Plate PrototypingAs technology continues to advance, we can expect to see further innovations in liquid cold plate prototyping, such as integration with IoT devices and enhanced cooling efficiency. Staying informed about these trends can help businesses stay competitive and adopt the latest cooling solutions.Quote Inquirycontact us