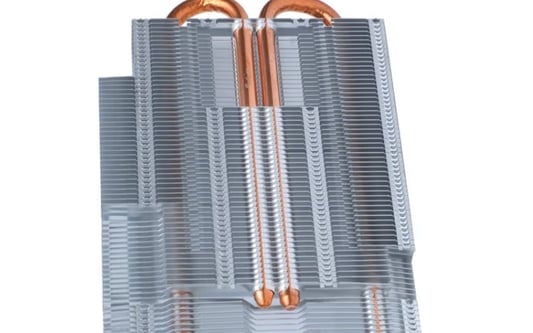

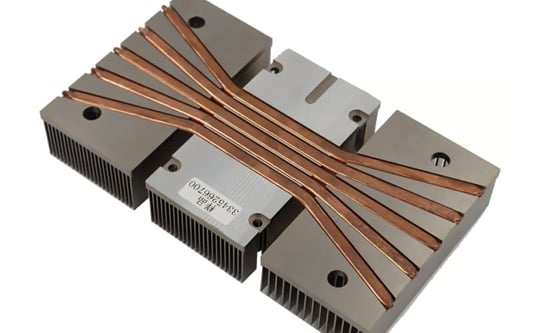

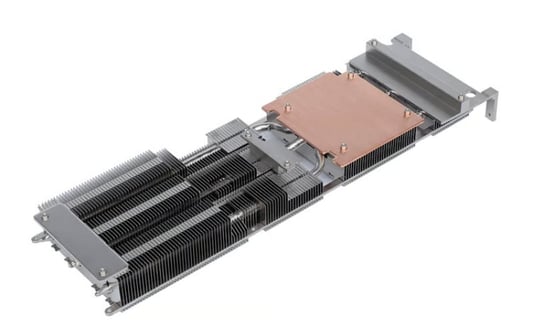

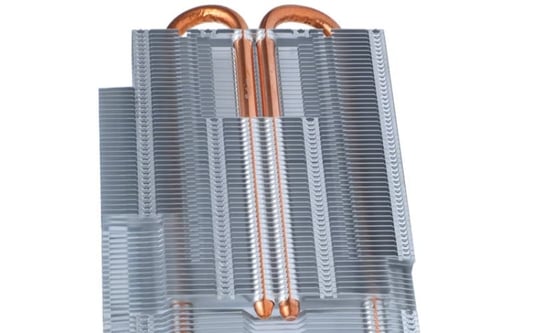

Copper vs. Stainless Steel: Which One is the Best for Your Home?When it comes to home appliances, choosing the right material is crucial. While stainless steel has dominated the market for quite some time, copper is now emerging as a popular alternative. But Why use copper instead of stainless steel?? In this article, we'll explore the benefits of copper and why it's worth considering for your home appliances.Eco-Friendly OptionOne of the most significant advantages of copper is its eco-friendliness. Copper is a naturally occurring metal, and it can be recycled infinitely without losing any of its properties. In contrast, stainless steel requires a significant amount of energy to produce, and recycling it is not as efficient as copper. By using copper, you're helping to reduce your carbon footprint and contribute to a sustainable future.High Thermal ConductivityCopper is an excellent heat conductor, which makes it ideal for cooking utensils. When you cook with copper pots and pans, the heat is evenly distributed, so you don’t have to worry about hot spots. The result is evenly cooked food, with rich flavors and textures. In addition, copper responds quickly to changes in temperature, which makes it perfect for delicate recipes.Durable and Long-lastingCopper is durable and long-lasting, which means you won't have to replace your appliances for a long time. Copper is resistant to corrosion, rust, and other forms of degradation, making it an ideal material for pipes and other plumbing fixtures. And if your copper appliance gets scratched, it can be easily repaired or polished to restore its original shine.Aesthetic AppealCopper has a unique and beautiful aesthetic appeal that can add sophistication to your home decor. Copper appliances and fixtures look luxurious and elegant, giving your home a modern and trendy look. Whether you're looking for a statement piece or a subtle addition to your kitchen, a copper appliance can do wonders for your home's overall appeal.Better Health BenefitsCopper has natural antibacterial properties, which makes it ideal for cooking and storing food. Copper-lined cookware has been found to reduce the risk of food poisoning by killing harmful bacteria. In addition, copper is an essential mineral that the body needs for various functions, such as producing red blood cells and maintaining a healthy immune system. By using copper appliances, you're ensuring that you're getting all the health benefits that copper has to offer.Less ReactivityCopper has less reactivity than stainless steel, which makes it ideal for storing acidic foods. Foods like tomato sauce, vinegar, and citrus juices can react with stainless steel and leave a metallic taste in your mouth. With copper, you can store these foods without worrying about any such reactions. It's worth noting that copper reacts with alkaline ingredients like baking soda, so it's not ideal for cooking certain recipes.Easy to Clean and MaintainCopper is a low maintenance material that's easy to keep clean. You can wipe down your copper appliances with a soft cloth and a mild soap solution to keep them looking shiny and new. If your copper appliance starts to tarnish, you can use various natural methods like lemon juice, baking soda, or vinegar to restore its original shine. Proper care and maintenance will ensure that your copper appliances last a long time.Cost-EffectiveCopper can be more expensive than stainless steel upfront. However, in the long run, copper is a cost-effective option due to its durability and longevity. Copper appliances can last for decades without the need for replacement or repair, which means you'll save money over time. In addition, copper has excellent resale value, so you can recoup some of your initial investment if you ever decide to sell your copper appliances.VersatileCopper is a versatile material that can be used in various applications. Apart from appliances, copper is used in electrical wiring, roofing, and architectural elements. Copper is also used in jewelry and decorative art, which shows its artistic versatility. With copper, the possibilities are endless.SummaryIn conclusion, copper is an excellent alternative to stainless steel for its eco-friendliness, high thermal conductivity, durability, aesthetic appeal, health benefits, less reactivity, easy maintenance, cost-effectiveness, and versatility. So, the next time you're looking for new appliances, consider copper instead of stainless steel.Quote InquiryContact us!