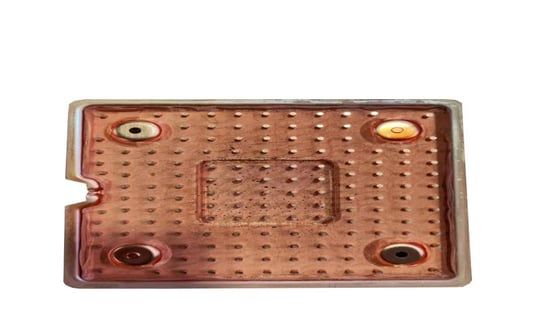

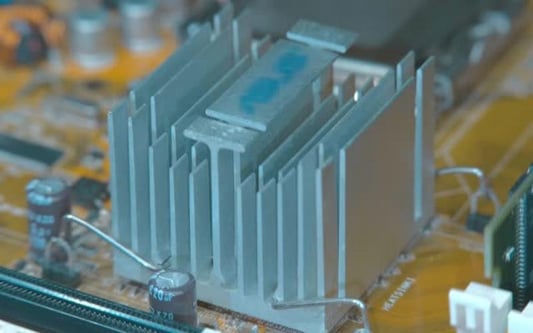

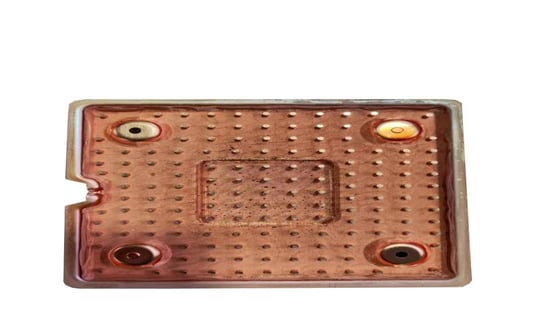

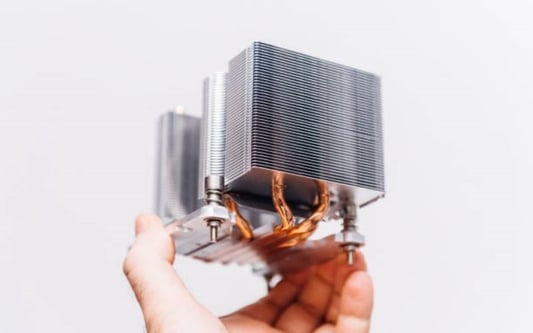

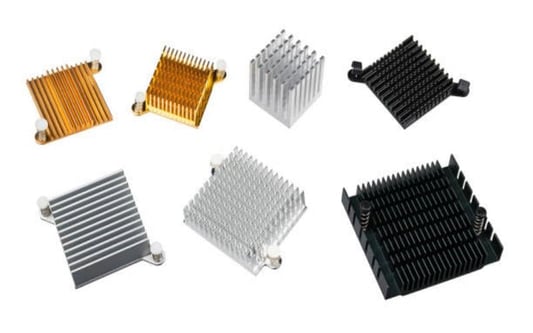

The Importance of a Custom COB LED Heat SinkWhen it comes to choosing the right heat sink for your COB LED lights, customization is key. A custom COB LED heat sink can greatly improve the performance and lifespan of your LED lights. In this article, we will explore the various aspects of a custom COB LED heat sink and why it is essential for optimal LED performance.What is a COB LED Heat Sink?A COB LED heat sink is a device that helps dissipate heat generated by the COB (Chip on Board) LED module. COB LEDs are known for their high-intensity output and energy efficiency. However, they also generate a significant amount of heat, which can negatively affect their performance and lifespan. A heat sink is designed to absorb and disperse this heat, ensuring that the LED operates within its optimal temperature range.Why Customization Matters?While off-the-shelf heat sinks may work for some applications, a custom COB LED heat sink offers several advantages. First and foremost, a custom heat sink is specifically designed to meet the unique requirements of your LED lighting system. This means that it will provide the most effective heat dissipation for your specific COB LED module.Additionally, a custom COB LED heat sink can be tailored to fit the available space in your lighting fixture. This is particularly important for applications where space is limited or unconventional. By customizing the heat sink, you can ensure that it fits perfectly and maximizes the cooling efficiency of your LED lights.The Design Considerations of a COB LED Heat SinkWhen designing a custom COB LED heat sink, there are several factors to consider. These include the power output of the LED module, the ambient temperature of the environment, and the desired operating temperature of the LED. The design should also take into account factors such as airflow, material selection, and surface area for heat dissipation.Proper thermal management is crucial for the performance and longevity of COB LEDs. By carefully considering these design factors, a custom COB LED heat sink can effectively remove excess heat and maintain the LED within its optimal operating temperature range.Material Selection of a COB LED Heat SinkThe choice of material for a custom COB LED heat sink is important, as different materials have varying thermal conductivity properties. Aluminum is commonly used for heat sinks due to its excellent thermal conductivity. It is lightweight, cost-effective, and readily available. Copper is another popular choice, known for its high thermal conductivity. However, it is more expensive and heavier compared to aluminum.Other materials, such as magnesium and graphite, have also been used for specialized applications. The material selection should be based on the specific requirements of the LED lighting system, considering factors such as thermal conductivity, weight, cost, and durability.Maximizing Heat DissipationOne of the primary goals of a custom COB LED heat sink is to maximize heat dissipation. This can be achieved through various design techniques. One common approach is to increase the surface area of the heat sink, allowing for more efficient heat transfer. This can be done by using fins, ridges, or other geometric designs on the heat sink's surface.Another technique is to enhance airflow around the heat sink. This can be achieved by incorporating fans or other cooling mechanisms into the lighting fixture. By improving the airflow, heat is carried away more effectively, preventing the LED from overheating.Benefits of a Custom COB LED Heat SinkInvesting in a custom COB LED heat sink offers several benefits. Firstly, it helps to extend the lifespan of the LED by keeping it within its optimal temperature range. This leads to improved reliability and reduced maintenance costs.Secondly, a custom heat sink enhances the overall performance of the LED. By effectively dissipating heat, the LED can operate at its full potential, providing brighter and more consistent light output.Lastly, a custom COB LED heat sink allows for greater flexibility in design and installation. With a customized heat sink, you can optimize the use of available space and ensure a seamless integration with your lighting system.ConclusionA custom COB LED heat sink is an essential component for maximizing the performance and lifespan of your LED lights. By choosing a customized solution, you can ensure effective heat dissipation, optimal thermal management, and improved overall performance. Make the investment in a custom COB LED heat sink and reap the benefits of brighter, more reliable LED lighting.Quote Inquiry