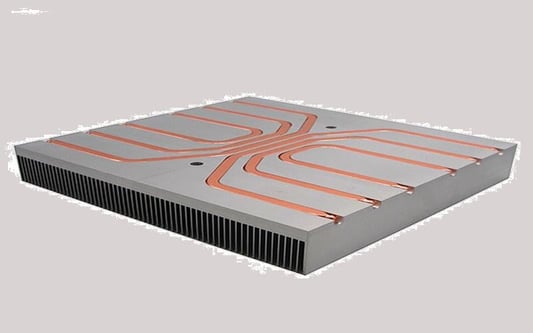

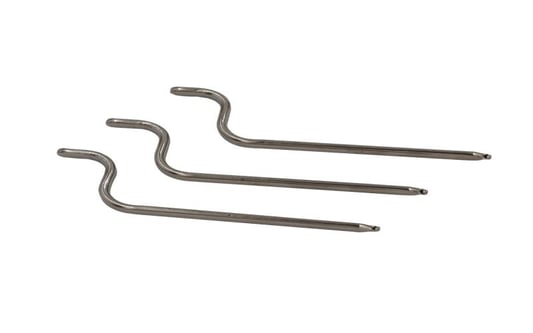

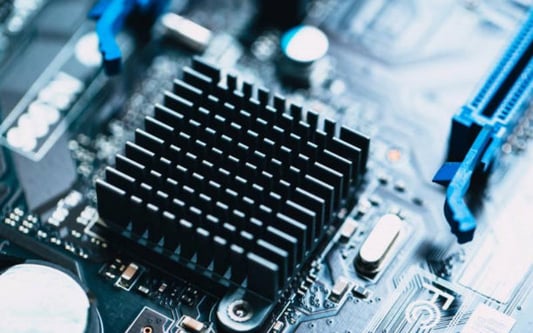

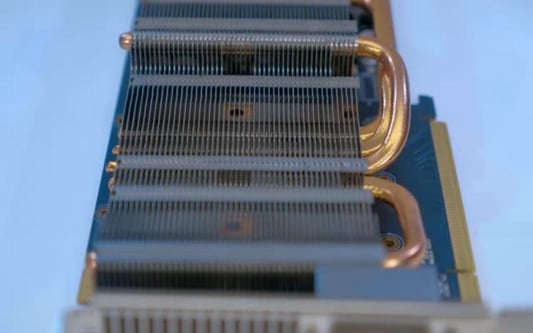

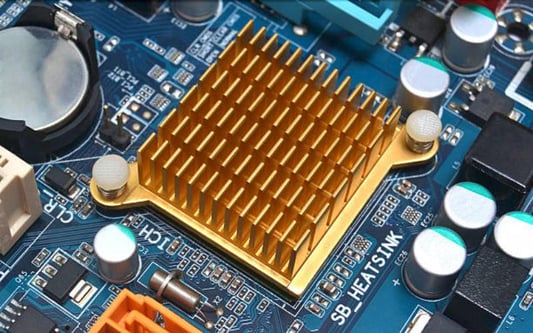

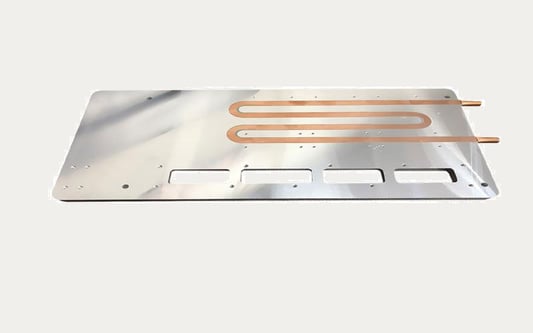

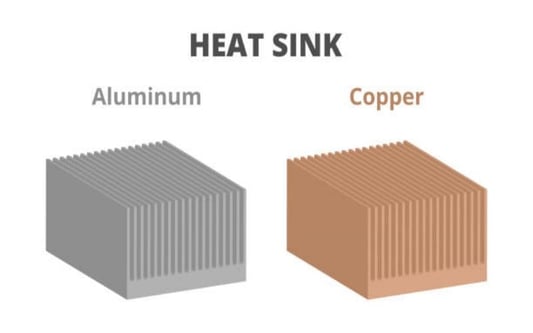

Heat pipe vs vapor chamber: Which is Better for Heat Dissipation?When it comes to heat dissipation in electronic devices, two popular solutions are heat pipes and vapor chambers. Both technologies excel at transferring heat away from hot components, but they have distinct differences that make them suitable for different applications. In this article, we will explore the differences between heat pipes and vapor chambers, and discuss their pros and cons in various scenarios.1. Heat Pipe: Efficient and Cost-Effective Heat TransferHeat pipes are widely used in many electronic devices to efficiently transfer heat from hot components to heat sinks. These devices consist of a sealed copper or aluminum tube with an inner wick structure and a small amount of working fluid, typically water or ammonia. The working fluid evaporates at the heat source, creating a pressure difference that drives it toward the colder end of the pipe. At the cold end, the vapor condenses, releasing the heat to the heat sink, and the condensed liquid returns to the hot end through capillary action.Heat pipes offer several advantages, such as high thermal conductivity, low thermal resistance, and passive operation. They can transfer large amounts of heat over long distances, enabling efficient cooling in compact designs. Heat pipes are also relatively cost-effective compared to other cooling solutions, making them a popular choice in many applications.2. Vapor Chamber: Enhanced Heat Spreading CapabilityVapor chambers, on the other hand, are more advanced heat transfer devices that provide enhanced heat spreading capability. They are essentially flat heat pipes, consisting of a sealed chamber with a wick structure and a working fluid. Vapor chambers are typically made of copper or aluminum and can have various shapes and sizes to fit different applications.Unlike heat pipes, vapor chambers are not limited to a single heat source. They can spread heat more evenly across a larger surface area, making them ideal for cooling high-power electronic components, such as CPUs and GPUs. The working fluid evaporates at the heat source, and the resulting vapor spreads throughout the chamber, condensing and releasing heat at the colder regions. This allows for efficient heat dissipation and prevents localized hotspots.3. Heat Pipe vs Vapor Chamber: Heat Transfer EfficiencyWhen it comes to heat transfer efficiency, both heat pipes and vapor chambers are highly effective. However, vapor chambers have a slight edge due to their larger surface area and improved heat spreading capability. This advantage becomes more significant when dealing with high-power components that generate concentrated heat.Heat pipes, on the other hand, excel in transferring heat over longer distances, making them suitable for applications where the heat source and heat sink are physically separated. They are also more cost-effective, making them a preferred choice in budget-conscious designs.4. Thermal Resistance and ConductivityThermal resistance and conductivity are crucial factors to consider when choosing between heat pipes and vapor chambers. Heat pipes typically have lower thermal resistance due to their smaller size and simpler design. They can quickly transfer heat from the source to the sink, ensuring efficient cooling.Vapor chambers, on the other hand, have higher thermal conductivity due to their larger surface area and improved heat spreading capability. They can distribute heat more evenly, reducing the risk of hotspots and improving overall cooling performance.5. Size and Weight ConsiderationsSize and weight are important considerations in many electronic devices, especially in portable devices like laptops and smartphones. Heat pipes are generally smaller and lighter than vapor chambers, making them more suitable for compact designs where space is limited.Vapor chambers, on the other hand, are larger and bulkier due to their flat design and larger surface area. While they may not be ideal for small devices, they offer superior heat spreading capability, making them a preferred choice in larger systems where heat dissipation is critical.6. Cost and Manufacturing ComplexityCost and manufacturing complexity are also important factors to consider when selecting a heat dissipation solution. Heat pipes are simpler in design and construction, making them more cost-effective to produce. They are widely available and can be easily integrated into existing designs.Vapor chambers, on the other hand, are more complex to manufacture and require higher precision. This complexity often leads to higher production costs, making them less cost-effective for budget-conscious designs. However, the enhanced heat spreading capability of vapor chambers may justify the higher cost in certain high-performance applications.7. Applications of Heat Pipes and Vapor ChambersHeat pipes and vapor chambers find applications in various industries and electronic devices. Heat pipes are commonly used in laptops, desktop computers, LED lighting, and telecommunications equipment. They are also found in aerospace and automotive applications, where efficient heat dissipation is crucial.Vapor chambers, on the other hand, are widely used in high-performance computing, such as gaming PCs and servers. They are also found in high-power LED lighting, advanced medical equipment, and electric vehicle battery cooling systems.8. Future Developments in Heat DissipationAs technology continues to advance, heat dissipation solutions are also evolving. Both heat pipes and vapor chambers are constantly being improved to meet the cooling demands of modern electronic devices.Researchers are exploring new materials and designs to enhance the thermal conductivity and heat spreading capability of these devices. Graphene-based heat pipes and vapor chambers, for example, show promising results in laboratory tests, offering even higher heat transfer efficiency.9. Choosing the Right Solution for Your ApplicationWhen selecting between heat pipes and vapor chambers for your application, it is essential to consider factors such as heat source characteristics, required heat spreading capability, size constraints, and budget limitations. Each technology has its advantages and limitations, and choosing the right solution will depend on the specific requirements of your application.10. ConclusionHeat pipes and vapor chambers are both effective heat dissipation solutions that have their strengths in different scenarios. Heat pipes offer efficient and cost-effective heat transfer over longer distances, while vapor chambers provide enhanced heat spreading capability and are ideal for cooling high-power components. By carefully evaluating your application's needs and considering the pros and cons of each technology, you can choose the right solution to ensure optimal heat dissipation and improve the reliability and performance of your electronic devices.Quote Inquiry