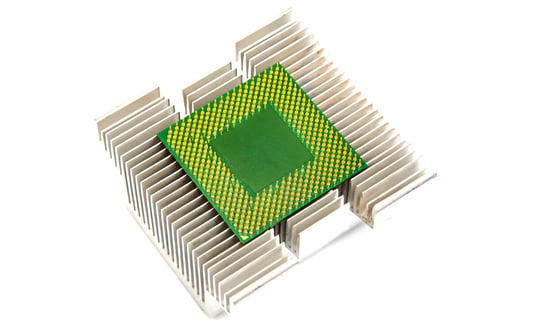

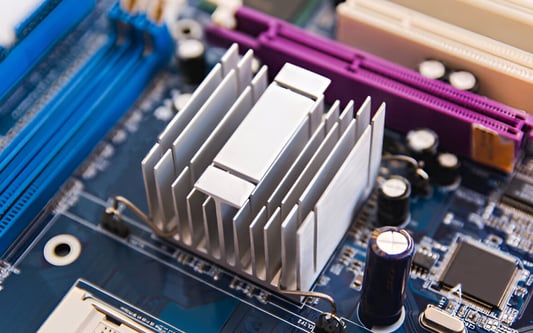

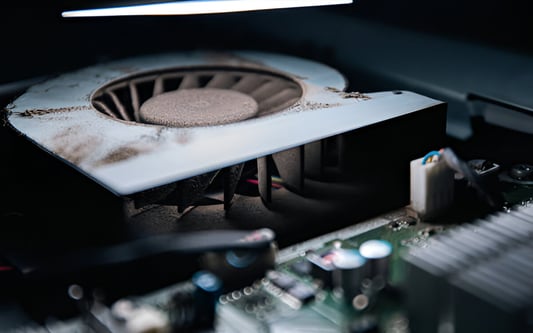

Why should a heat sink be black?? A Comprehensive Guide.Heat sinks are integral components of electronics and machinery that tend to heat up during operation. They help in dissipating heat, thus preventing overheating and damage to the system. But have you ever wondered why heat sinks are predominantly black? In this article, we'll look at the reason behind this common color choice.1. Black is a Great Absorber of HeatHeat naturally moves from hot to cold areas, so heat sinks function by absorbing heat and transferring it away from the system. Black surfaces absorb more heat than other colors and, therefore, are more effective at conducting the heat away from the system. In comparison, lighter colors reflect heat, reducing their effectiveness as heat sinks.2. Black Coatings Enhance Heat DissipationTo enhance the performance of heat sinks, manufacturers commonly use coatings that increase their emissivity, which is the ability to release heat. These coatings are usually black in color because black is an excellent emitter of heat, enabling the heat sink to efficiently dissipate heat into the surrounding air and power up the system.3. Black is More Aesthetically PleasingAside from the functional benefits, heat sink color also holds an aesthetic value. Black is the most commonly chosen color due to its sleek and modern look, making it a satisfying color choice for designers and manufacturers.4. Black is EnduringBlack coatings are relatively durable and can withstand high temperatures, which makes them an ideal fit for heat sinks. Plus, they will not corrode or rust easily and can maintain their color without fading or dulling over extended periods.5. Black is a Cost-Effective OptionHeat sinks can be manufactured from various materials, each with a range of prices. Paints, coatings, and anodizing processes used to color heat sinks have their own different treatment costs, and black is often the most cost-effective color to produce. Therefore, black heat sinks offer a cost-effective solution while still providing all the necessary functional benefits.6. Black Absorbs Electromagnetic WavesHeat sinks also function as EMI (electromagnetic interference) shields, blocking electromagnetic signals from interfering with the operations of the device. Black materials are often better at absorbing electromagnetic waves than other colors, providing additional benefits in electromagnetic interference protection.7. Black is Readily AvailableThe thermodynamic properties of black coatings make them highly desirable, and therefore manufacturers have readily available supplies of black coatings. As a result, the black color is the go-to choice for heat sinks across various industries.8. Black is a Standard Color for Technical ProductsBlack is the standard color for many technical products, including heat sinks. Using a standard color helps with industry consistency, and using black makes it easier for consumers to identify and distinguish between different technical components.9. Black Maintains its Cool TemperatureOne of the primary purposes of heat sinks is to keep the component temperatures from reaching critical levels. Because black heat sinks dissipate heat so efficiently, they can maintain a cooler temperature than their counterparts. 10. Other Colors Are Also SuitableAlthough black heat sinks tend to be the most commonly used color, other colors such as blue, green, and gold are also possible options. These colors can provide other aesthetic values, but none can match the thermodynamic and cost-effective benefits of black heat sinks.ConclusionBlack has long been the traditional color choice for heat sinks, and for various good reasons. It's superb at absorbing and dissipating heat, offers cost-effective solutions, and enhances device performance and longevity. While other colors might offer aesthetic benefits, none can match the functional and practical advantages of black heat sinks.Quote InquiryContact us