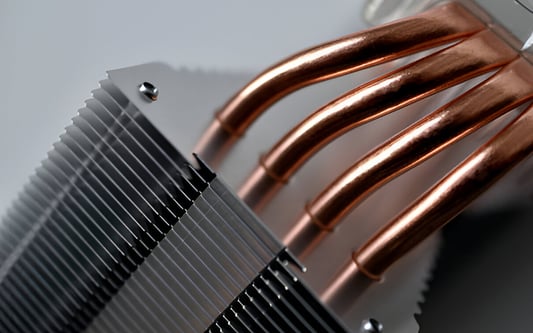

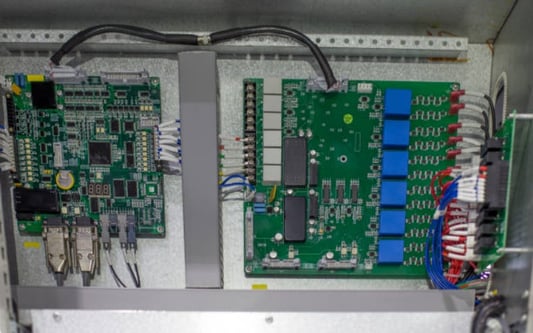

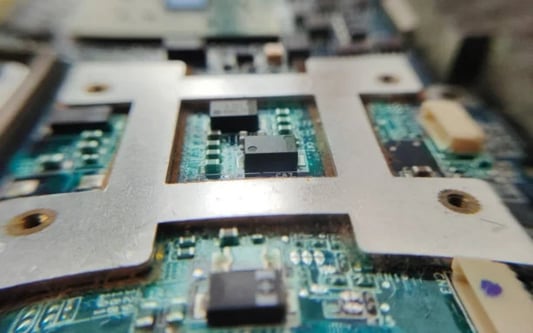

What Are Heat Sinks and Why Are They Important?Heat sinks are important components that help dissipate heat generated by electronic devices such as CPUs, GPUs, and other similar components. They are designed to draw heat away from the device, transfer it to another medium, and then dissipate it into the surrounding environment. Without proper heat sinks, electronic devices can overheat and malfunction, leading to reduced performance, shortened lifespan, and even permanent damage.1. Aluminum Heat SinksAluminum is a popular material for heat sinks because it is lightweight, affordable, and has a good thermal conductivity. It is easy to machine and offers good heat dissipation for most applications. However, it may not be the best option for high-power applications or when the device is continually subjected to high heat loads.2. Copper Heat SinksCopper is an excellent heat conductor, making it an ideal material for heat sinks. It is more expensive than aluminum, but it offers better thermal conductivity and higher strength. Copper is commonly used in high-power applications that generate a significant amount of heat, such as power amplifiers, thyristors, and other high-voltage devices.3. Thermoplastics Heat SinksThermoplastics are lightweight and corrosion-resistant, making them ideal for use in harsh environments. They offer excellent thermal conductivity and are low cost. Some thermoplastics even allow for easy molding and customization, making them an attractive option for consumer electronics and other applications.4. Graphene Heat SinksGraphene is a relatively new material that has shown great potential in thermal management applications. It is an excellent conductor of heat and is lightweight, flexible, and strong. Graphene heat sinks are still in the experimental phase, but they show promise for high-tech applications that require advanced thermal management solutions.5. Diamond Heat SinksDiamond is one of the best heat sink materials available, offering an extremely high thermal conductivity and excellent strength. However, diamond is expensive and difficult to manufacture into heat sinks, making it a less common material for most applications.6. Composite Heat SinksComposite heat sinks are constructed from multiple materials, each with unique thermal properties. By combining different materials, engineers can create customized heat sink solutions that offer excellent heat dissipation properties for specific applications.7. Phase-Change Heat SinksPhase-change heat sinks use a heat pipe that contains a coolant that changes phase from liquid to gas as it absorbs heat. This change in phase allows for efficient heat transfer and dissipation, making phase-change heat sinks an attractive solution for high-performance applications.8. Liquid Metal Heat SinksLiquid metal heat sinks utilize a liquid metal alloy that has a high thermal conductivity and low viscosity. These alloys can be molded into complex shapes, making them ideal for customized heat sink solutions. However, liquid metal heat sinks can be more expensive and require specialized handling and manufacturing processes.9. Carbon Nanotube Heat SinksCarbon nanotubes are extremely thin tubes made of carbon atoms. They offer an excellent thermal conductivity and mechanical strength, making them ideal for heat sink applications. However, carbon nanotube heat sinks are still in the experimental phase and are not yet commercially available.10. Ceramic Heat SinksCeramic materials offer excellent thermal conductivity, electrical insulation, and thermal shock resistance. Ceramic heat sinks are typically used in high-temperature applications that require high mechanical strength and reliability.heat sink materials, aluminum heat sinks, copper heat sinks, thermoplastics heat sinks, graphene heat sinks, diamond heat sinks, composite heat sinks, phase-change heat sinks, liquid metal heat sinks, carbon nanotube heat sinks, ceramic heat sinksWhat are the best heat sink materials?? A Comprehensive GuideDiscover the top heat sink materials for electronic devices in this informative article. Find out the benefits and drawbacks of materials like aluminum, copper, graphene, and diamond, and learn which materials are the ideal choice for specific applications.best aluminum heat sinks for electronic devices, copper heat sinks for high-power applications, custom thermoplastics heat sinks for consumer electronics, experimental graphene heat sinks for high-tech applications, heat dissipation solutions with composite heat sinks, superior phase-change heat sinks for high-performance devices, advanced liquid metal heat sinks for custom applications, carbon nanotube heat sinks for future innovations, ceramic heat sinks for high-temperature reliabilityQuote InquiryContact us