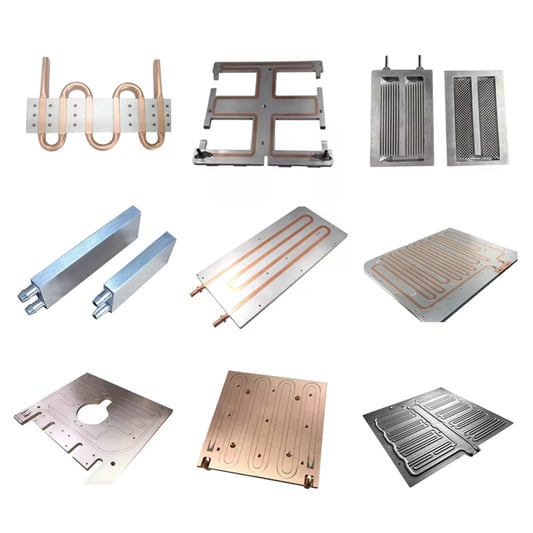

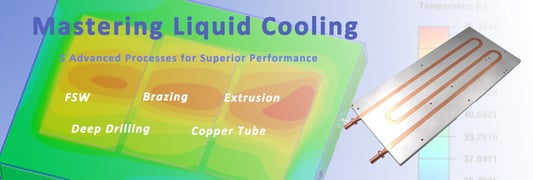

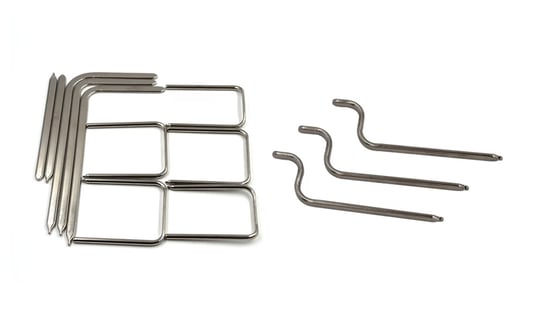

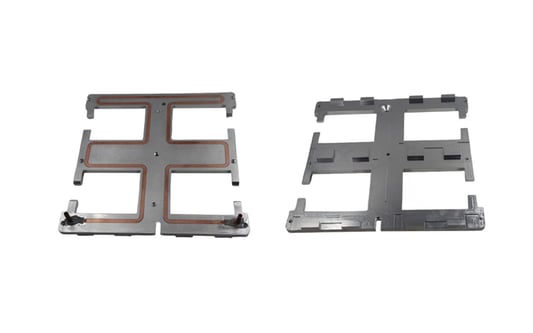

Understanding the Basics of Liquid Cold PlatesA liquid cold plate is a type of heat sink that is used to cool electronic components. It consists of a flat metal plate that has channels or grooves on its surface. These channels are filled with a liquid coolant that is circulated to absorb and dissipate heat from the electronic device.How Does a Liquid Cold Plate Work?When the electronic component heats up, the heat is transferred to the liquid coolant flowing inside the cold plate. As the liquid absorbs the heat, it evaporates and moves away from the hot spot, carrying the heat with it. The hot vapor then condenses at a cooler part of the cold plate, releasing the heat energy and turning back into a liquid.Advantages of Using Liquid Cold PlatesLiquid cold plates offer several advantages over traditional air cooling methods. They provide more efficient heat transfer, allowing for better thermal management of electronic components. They are also quieter and require less maintenance compared to fans or air vents.Types of Liquid Coolants Used in Cold PlatesThe choice of liquid coolant used in a cold plate depends on the specific requirements of the electronic device being cooled. Common liquid coolants include water, glycol-based solutions, and dielectric fluids. Each coolant has its own unique thermal properties and benefits.Design Considerations for Liquid Cold PlatesWhen designing a liquid cold plate, several factors must be taken into account, such as the size and shape of the electronic component, the flow rate and pressure of the coolant, and the material of the cold plate. Proper design is crucial for optimal heat dissipation.Applications of Liquid Cold PlatesLiquid cold plates are commonly used in high-powered electronic devices such as power converters, laser diodes, and medical imaging equipment. They are also used in data centers and telecommunications infrastructure to cool server racks and networking equipment.Efficiency of Liquid Cold PlatesLiquid cold plates are highly efficient at heat dissipation, making them ideal for cooling sensitive electronic components that generate a lot of heat. Their ability to quickly absorb and dissipate heat helps prevent overheating and prolong the lifespan of electronic devices.Installation and Maintenance of Liquid Cold PlatesInstalling a liquid cold plate requires careful consideration of the mounting process, ensuring that there is proper contact between the cold plate and the electronic component. Regular maintenance, such as checking for leaks and refilling the coolant, is essential for optimal performance.Future Trends in Liquid Cooling TechnologyAs electronic devices continue to advance in complexity and power, the demand for more efficient cooling solutions such as liquid cold plates is expected to rise. Innovations in materials and design are driving the development of even more compact and effective liquid cooling systems.ConclusionIn conclusion, a liquid cold plate is a crucial component in the thermal management of electronic devices, providing efficient and reliable cooling solutions. By understanding how liquid cold plates work and their many advantages, manufacturers can improve the performance and longevity of their electronic products.Quote InquiryContact us