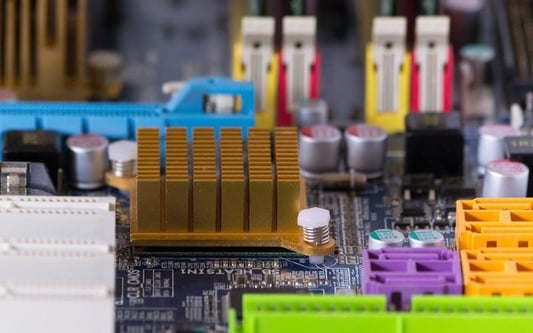

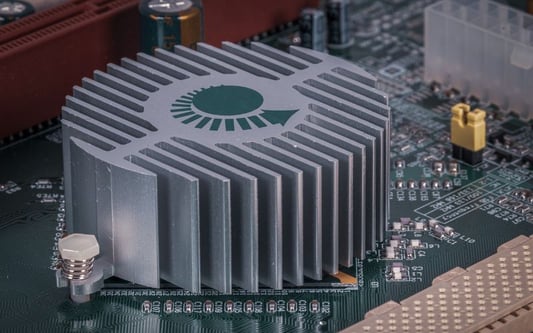

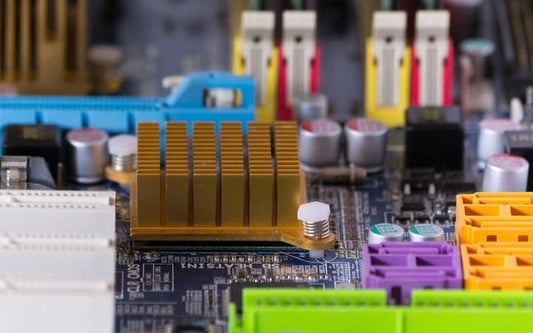

Understanding the Basics of HeatsinksWhen it comes to electronic devices, heatsinks play a vital role in dissipating heat and ensuring optimal performance. A heatsink is a passive cooling component that absorbs and disperses heat generated by electronic components. It is crucial in preventing overheating and prolonging the lifespan of electronic devices.Choosing the Right MaterialsThe manufacturing process of a heatsink begins with selecting the appropriate materials. Aluminum and copper are commonly used due to their high thermal conductivity. Aluminum is lightweight and cost-effective, while copper offers superior heat dissipation. The choice of material will depend on the specific requirements of the electronic device.Designing the HeatsinkThe next step in manufacturing a heatsink is designing its structure. The design should optimize surface area to enhance heat dissipation. Fins, grooves, and channels are commonly incorporated into the heatsink design to increase the efficiency of heat transfer. Advanced computer-aided design (CAD) software is utilized to create precise and efficient heatsink designs.Extrusion ProcessOne of the most common methods used in heatsink manufacturing is extrusion. In this process, a heated aluminum or copper billet is forced through a die to create the desired heatsink shape. Extrusion allows for complex geometries and efficient production of heatsinks in large quantities. It is a cost-effective and versatile manufacturing method.CNC MachiningFor heatsinks with intricate designs or custom specifications, computer numerical control (CNC) machining is used. CNC machines are programmed to cut and shape solid blocks of aluminum or copper into heatsinks with high precision. This method is ideal for low-volume production or prototyping of heatsinks.Bonding and AssemblyAfter the heatsink components are manufactured, they are bonded together using techniques such as soldering, welding, or adhesive bonding. The fins, base, and other elements of the heatsink are assembled to create a complete cooling solution. Precision is key in ensuring the heatsink functions effectively.Surface TreatmentTo improve thermal performance and corrosion resistance, heatsinks undergo surface treatment processes. Anodizing is a common method used to create a protective oxide layer on aluminum heatsinks. This layer enhances durability and improves thermal conductivity. Other surface treatments include painting and powder coating.Quality Control and TestingBefore being installed in electronic devices, heatsinks undergo rigorous quality control checks and testing. Thermal performance, dimensional accuracy, and structural integrity are evaluated to ensure the heatsink meets specifications. Quality control measures are essential to guarantee the reliability and efficiency of the heatsink.Packaging and ShippingOnce the heatsinks pass quality control, they are packaged and shipped to manufacturers of electronic devices. Packaging materials such as foam inserts and protective boxes are used to prevent damage during transportation. Heatsinks are delivered in large quantities to meet the demands of the electronics industry.ConclusionManufacturing a heatsink involves a series of precise steps, from material selection to quality control. By understanding the basics of heatsinks and employing advanced manufacturing techniques, manufacturers can produce efficient and reliable cooling solutions for a wide range of electronic devices.Quote InquiryContact us!