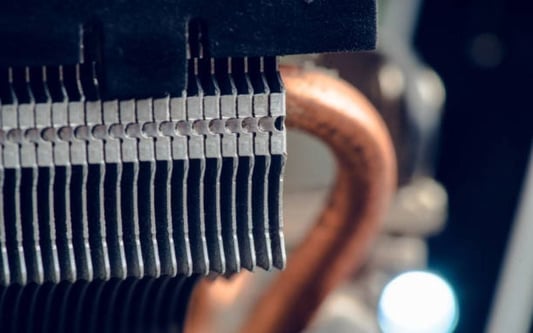

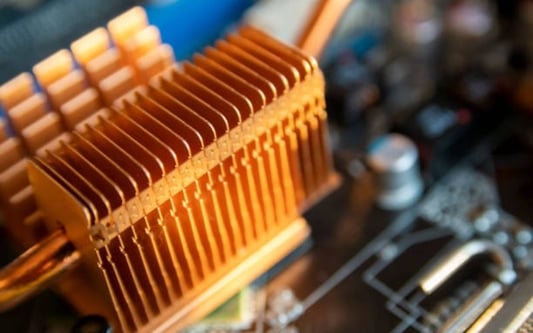

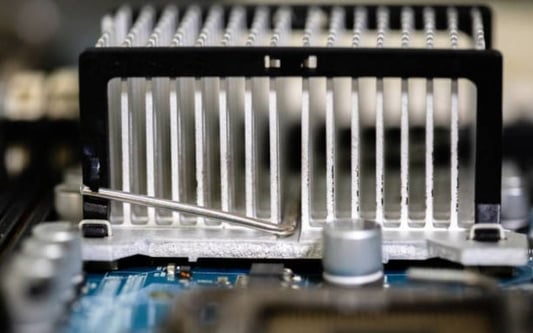

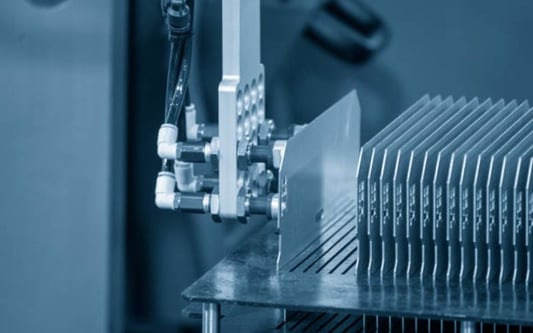

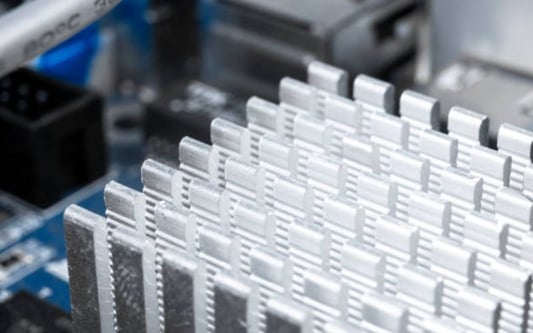

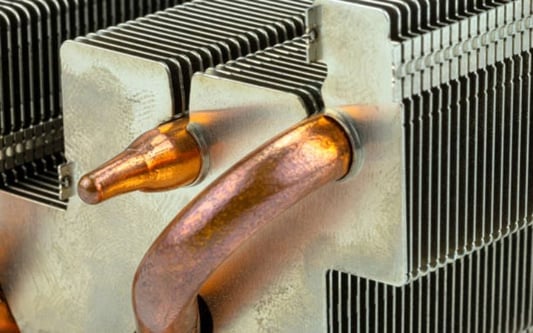

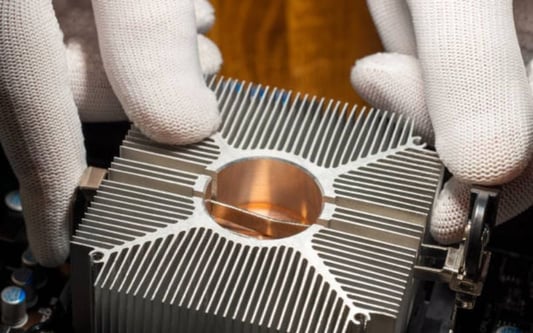

Do heat sinks go bad?? Understanding the Lifespan of Heat SinksWhen it comes to keeping electronic devices cool, heat sinks play a crucial role in dissipating excess heat. However, over time, heat sinks may begin to fail, leading to increased temperatures and potential damage to the device. In this article, we will explore the question "Do heat sinks go bad?" and provide insights on how to prolong their lifespan.What are Heat Sinks?Before we address the question of whether heat sinks can go bad, let's first define what heat sinks are. Heat sinks are passive cooling systems that work by transferring heat away from a device to a larger surface area where it can dissipate. They are commonly used in electronic devices such as CPUs, GPUs, and power amplifiers, among others.How Do Heat Sinks Work?Heat sinks work by using a combination of thermal conduction and thermal radiation. They are made up of materials like aluminum or copper which are highly conductive and help to spread heat quickly across the surface of the heat sink. The larger surface area of the heat sink also helps to radiate the heat away from the device, preventing it from overheating.Can Heat Sinks Go Bad?While heat sinks are designed to last for the lifetime of an electronic device, they can go bad if they become damaged or are not maintained properly. Common issues that can cause heat sinks to fail include a buildup of dust and debris, incorrect installation, or damage from physical impacts.Effects of a Failed Heat SinkIf a heat sink fails, the device it is trying to cool will start to heat up at a faster rate. This can result in decreased performance, stability issues, and potentially permanent damage to the device. It is important to catch and address a failed heat sink as soon as possible to avoid these consequences.Signs of a Failing Heat SinkThere are several signs that can indicate a heat sink is failing. The most obvious sign is when a device begins to overheat and experience performance issues. However, other signs can include unusual noises from the device, visible damage to the heat sink, or excessive dust buildup on the surface of the heat sink.How to Prolong Heat Sink LifespanThere are several simple steps you can take to prolong the lifespan of your heat sink. The first is to ensure that it is installed correctly, with proper thermal paste and mounting pressure. Additionally, it is recommended to regularly clean the surface of the heat sink to remove any dust or debris buildup that could impact its performance. Finally, if you notice any signs of a failing heat sink, it is important to address the issue immediately to avoid further damage.When to Replace a Heat SinkIf a heat sink has become damaged or is no longer able to effectively cool the device it is intended for, it may be necessary to replace it. In some cases, a simple cleaning may be enough to restore the heat sink's functionality, but in more severe cases, a full replacement may be necessary.ConclusionHeat sinks play an important role in keeping electronic devices cool and preventing damage due to overheating. While they are designed to last for the lifetime of a device, there are several factors that can cause them to fail over time. By understanding the signs of a failing heat sink and taking steps to prolong their lifespan, you can help ensure that your electronic devices continue to run smoothly for years to come.Quote InquiryContact us!