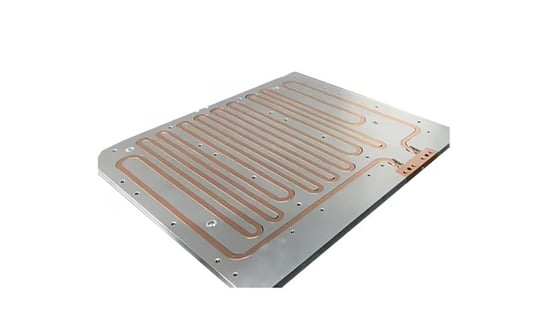

What is a vapor chamber heat spreader?A vapor chamber heat spreader is a highly efficient cooling solution used in electronics to manage heat dissipation. It consists of a flat plate containing a wick structure and a small amount of working fluid. When the heat source applies thermal energy to the working fluid, it evaporates and spreads throughout the chamber, reducing the temperature of the electronics component.Advantages of Vapor Chamber Heat SpreadersOne of the main advantages of vapor chamber heat spreaders is their superior thermal conductivity. Compared to traditional heat spreaders, vapor chambers can transfer heat more effectively, leading to improved overall performance and reliability of electronic devices. Additionally, vapor chamber heat spreaders are lightweight and thin, making them ideal for compact electronic devices.Applications of Vapor Chamber Heat SpreadersVapor chamber heat spreaders are commonly used in high-performance electronics such as gaming laptops, graphics cards, and servers. These devices generate a significant amount of heat, which can be effectively managed by utilizing vapor chamber technology. By incorporating vapor chamber heat spreaders, manufacturers can ensure the stability and longevity of their products.Efficiency of Vapor Chamber Heat SpreadersThe design of vapor chamber heat spreaders allows for more uniform temperature distribution across the surface of electronic components. This uniformity helps prevent hotspots and thermal throttling, allowing devices to operate at optimal performance levels. By efficiently dissipating heat, vapor chamber heat spreaders contribute to the longevity of electronic devices.Customization Options for Vapor Chamber Heat SpreadersManufacturers have the flexibility to customize vapor chamber heat spreaders to meet specific design requirements. Variations in size, shape, and material composition allow for tailored cooling solutions that can optimize the performance of electronic devices. Customized vapor chamber heat spreaders can improve heat dissipation and enhance overall system efficiency.Cost Considerations of Vapor Chamber Heat SpreadersWhile vapor chamber heat spreaders offer numerous benefits, they can be more expensive to produce than traditional cooling solutions. The advanced technology and materials used in vapor chambers contribute to higher manufacturing costs. However, the long-term benefits of improved performance and reliability often outweigh the initial investment for many electronic manufacturers.Future Trends in Vapor Chamber Heat Spreader DevelopmentAs electronic devices continue to become more powerful and compact, the demand for efficient cooling solutions like vapor chamber heat spreaders is expected to rise. Manufacturers are constantly innovating to improve the performance and cost-effectiveness of vapor chamber technology. Future developments may include increased customization options and enhanced thermal management capabilities.Environmental Impact of Vapor Chamber Heat SpreadersVapor chamber heat spreaders contribute to the sustainability of electronic devices by improving energy efficiency and reducing heat-related failures. By effectively dissipating heat, vapor chamber technology can help prolong the lifespan of electronic components and minimize electronic waste. This focus on sustainability aligns with broader environmental initiatives in the electronics industry.Comparing Vapor Chamber Heat Spreaders to Other Cooling SolutionsIn comparison to traditional heat sinks and heat pipes, vapor chamber heat spreaders offer superior thermal conductivity and heat dissipation capabilities. While heat sinks rely on convection to dissipate heat, vapor chambers use phase-change technology to transfer thermal energy more efficiently. The use of vapor chamber heat spreaders can lead to improved overall system performance and reliability.ConclusionVapor chamber heat spreaders are a cutting-edge cooling solution that offers superior thermal management for high-performance electronic devices. With their efficiency, customization options, and environmental benefits, vapor chamber technology is poised to play a crucial role in the future of electronics cooling. By incorporating vapor chamber heat spreaders into electronic designs, manufacturers can ensure optimal performance and reliability for a wide range of applications.Quote InquiryContact us