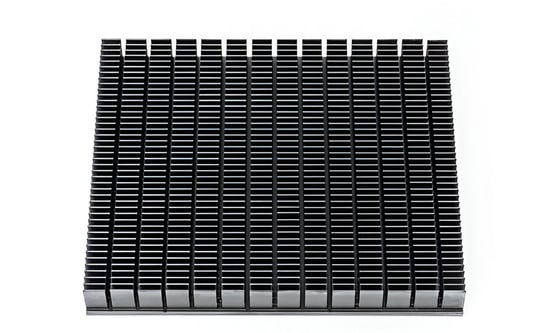

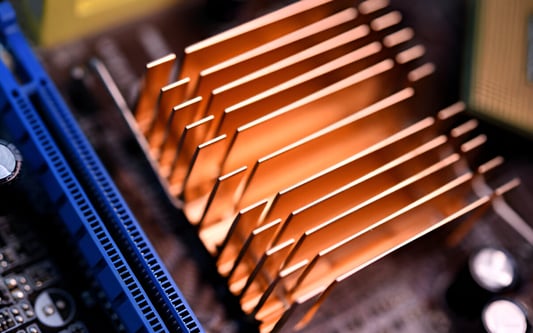

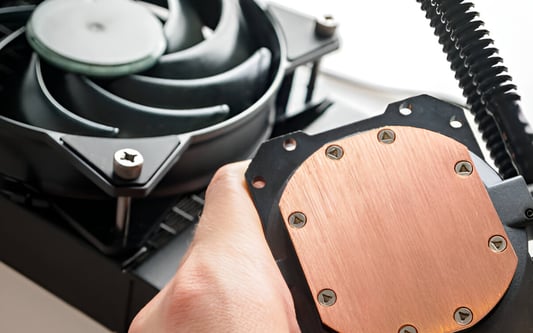

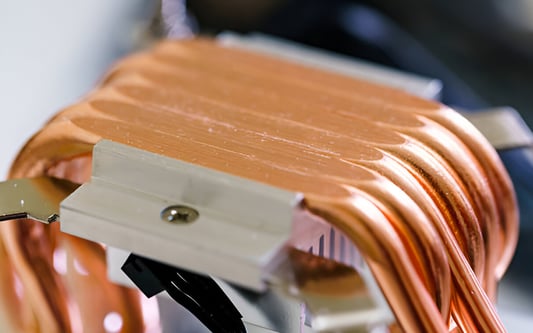

IntroductionHeat sinks are often used in electronics to dissipate heat away from components. These components include microprocessors, graphic processing units, and other electrical systems. The efficiency of a heat sink is essential to ensure the longevity of your electronics and prevent them from burning out. In this article, we will be discussing the requirements for a heat sink.Size of Heat SinkThe size of a heat sink is a critical factor in its efficiency. The size should be proportional to the heat that needs to be dissipated by the heat sink. If the heat sink is too small, it will not be able to dissipate heat effectively, leading to overheating of the component. On the other hand, if the heat sink is too big, it can make your device bulky and increase production costs without providing additional cooling benefits.Choice of MaterialHeat sinks are made from various materials, including aluminum, copper, and a combination of these materials. The choice of material is crucial since it affects the heat dissipation capability of the heat sink. Copper is an excellent heat conductor and can dissipate heat faster than aluminum; however, it is also more expensive than aluminum.Fin DensityHeat sink fins help to increase the surface area, allowing for more efficient heat dissipation. The fin density should be taken into consideration while designing the heat sink to ensure maximum heat transfer. High fin density can limit airflow, while low fin density will not allow for adequate heat dissipation.AirflowAirflow is another critical factor to consider when designing a heat sink. Enough air should be allowed to pass through the heat sink to dissipate the generated heat. Airflow can be improved in various ways, such as using a fan or positioning the heat sink in a way that promotes natural convection.Thermal Interface MaterialA thermal interface material (TIM), such as thermal grease, is used between the heat sink and the component to increase thermal conductivity. The effectiveness of the TIM plays a crucial role in the dissipation of heat. A thermal interface material can be used to ensure even heat distribution and maximum heat transfer from the component to the heat sink.Thermal ResistanceThermal resistance is the resistance to heat flow between two materials. The resistance should be kept as low as possible to allow for maximum heat transfer. Proper thermal management can help minimizing thermal resistance. Heat Source PlacementThe placement of the heat source is crucial when designing a heat sink system. The heat source should be positioned at the center of the heat sink for maximum heat dissipation. Otherwise, components that are too far away from the heat source and the heat sink may not benefit significantly.The Shape of Heat SinkThe shape of the heat sink can impact its performance. The shape and size should be chosen based on the space and layout available on the electronic device to ensure maximum surface area and efficient heat dissipation.Location of Heat SinkHeat sinks should be placed in an area where they can efficiently dissipate heat. The location should be far away from any obstructions that may limit airflow. This allows for maximum heat dissipation and prevents the accumulation of heat on the heat sink.Overall DesignThe overall design of a heat sink system should take into account the specific requirements of your device. A properly designed heat sink system can ensure optimal thermal management, prevent overheating and extend your electronics' lifespan. heat sink, heat sink requirements, thermal management, copper heat sink, aluminum heat sinkWhat are the requirements for a heat sink?? | Heat Sink BasicsLearn the crucial heat sink requirements and thermal management tips to keep your electronic components cool. Read to know more about copper and aluminum heat sinks.Quote InquiryContact us