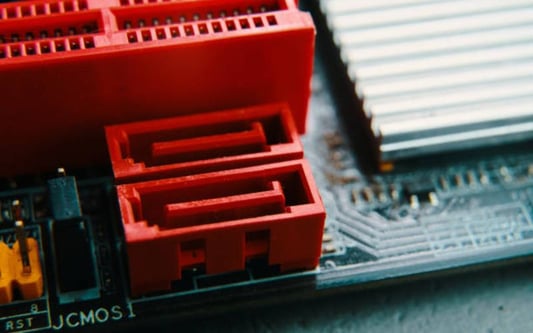

Introduction: Understanding the BasicsWhen it comes to cooling components in various electronic devices, heat sinks and fins play a crucial role. While both are used to dissipate heat, there are key differences between the two.Composition: Materials UsedHeat sinks are typically made of a high thermal conductivity material such as aluminum or copper, while fins are thin protrusions made of the same materials that are attached to the heat sink. This composition helps in effectively transferring heat away from the component.Functionality: Cooling MechanismHeat sinks work by absorbing and transferring heat away from the component through conduction, while fins increase the surface area for better heat dissipation through convection. This process helps in keeping the component cool and functioning optimally.Design: Shape and StructureHeat sinks come in various shapes and sizes, depending on the specific application and component it is cooling. Fins, on the other hand, are usually thin and elongated, resembling the appearance of a radiator for efficient cooling.Installation: Attachment to ComponentsHeat sinks are directly attached to the component using thermal paste or adhesive, ensuring maximum contact for heat transfer. Fins are often attached to the heat sink itself, extending the surface area for enhanced cooling performance.Efficiency: Heat Dissipation RateHeat sinks are known for their ability to quickly absorb and disperse heat from the component, thanks to their large surface area. Fins further enhance this process by increasing the contact area with the surrounding air for faster cooling.Applications: Common UsesHeat sinks are commonly used in various electronic devices such as CPUs, GPUs, and power transistors to prevent overheating and ensure optimal performance. Fins are often found in heat sink assemblies for air-cooled systems in computers and appliances.Effectiveness: Thermal ManagementHeat sinks play a crucial role in thermal management by effectively dissipating heat from the component, while fins help in maximizing the cooling efficiency by increasing the contact surface area. This combined effort ensures that the component operates within safe temperature limits.Cost: Price VariationsHeat sinks tend to be more expensive than fins due to their solid construction and thermal conductivity properties. Fins, being simpler in design and structure, are generally more cost-effective and easier to produce in large quantities.Conclusion: Choosing the Right OptionIn summary, while both heat sinks and fins serve the purpose of cooling components, they differ in terms of composition, functionality, design, and cost. Understanding these differences can help in selecting the right option for efficient thermal management in electronic devices.Quote InquiryContact us!