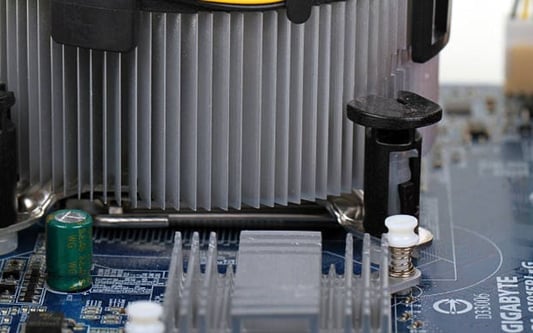

The Functionality of a Heat PipeHeat pipes are widely used for transferring heat from one point to another. They are a highly efficient, passive, and reliable cooling solution. A typical heat pipe consists of a sealed pipe that is evacuated and charged with a working fluid. The fluid inside the pipe absorbs the heat from the heat source and evaporates. It then condenses and releases the heat at the other end of the heat pipe, where the heat is dissipated into the surrounding environment.Thermal Conductivity of a Heat PipeHeat pipes use a combination of thermal conductivity, latent heat and capillary action for efficient heat transfer. The thermal conductivity of a heat pipe is extremely high. This means that heat can be transferred over long distances with minimal thermal resistance, making heat pipes an effective thermal management solution.The Efficiency of Heat PipesHeat pipes are very efficient at transferring heat because they rely on phase change of the working fluid. This allows them to transport large amounts of heat over very small distances, making them suitable for use in compact, high power devices.Capacity of Heat PipesThe capacity of a heat pipe depends on several factors, including the diameter, length, and working fluid used. Heat pipes can handle heat loads ranging from a few watts to several hundred watts, making them suitable for use in a variety of applications.Applications of Heat PipesHeat pipes are widely used in electronic devices, power electronics, telecommunications, aerospace, and many other industries. They are particularly useful in applications where space is limited, and where there is a need for effective thermal management.Thermal Management Using Heat PipesHeat pipes provide an effective and reliable thermal management solution for a range of applications. They can be used to transfer heat away from hot spots and to distribute heat more evenly in a system. Heat pipes are particularly useful in applications where other cooling methods may not be practical or efficient.The Durability and Reliability of Heat PipesHeat pipes are highly durable and reliable, with no moving parts to wear out or fail. Their sealed design means that they are impervious to most environmental factors, making them suitable for use in harsh environments.The Energy Efficiency of Heat PipesHeat pipes are very energy efficient, as they require no external energy source to operate. They rely on natural conduction and evaporation of the working fluid to transfer heat, making them an environmentally friendly solution.Considerations When Using Heat PipesWhen using heat pipes, there are several considerations to take into account. These include the diameter and length of the heat pipe, the working fluid used, and the operating temperature range. It is important to choose the right heat pipe for the application to ensure efficient and reliable thermal management.ConclusionHeat pipes are a highly effective and efficient thermal management solution. They offer a range of advantages, including high thermal conductivity, reliability, durability, and energy efficiency. Heat pipes are widely used in a range of applications, from electronics to aerospace, and are a critical component in many modern devices.Quote InquiryContact us!