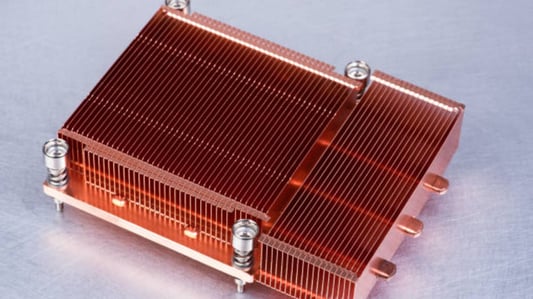

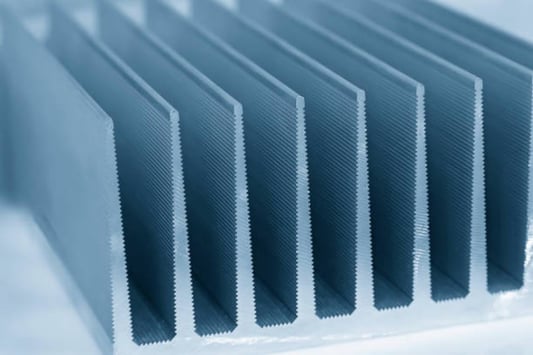

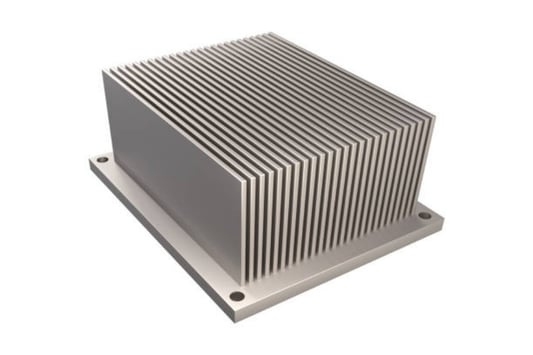

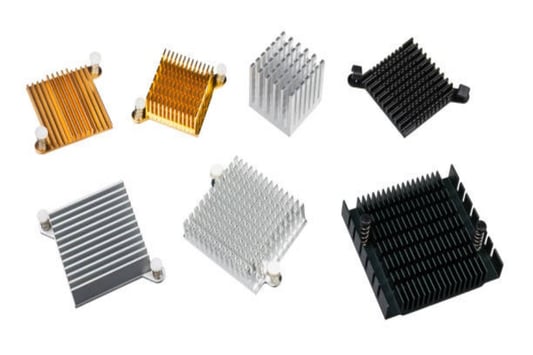

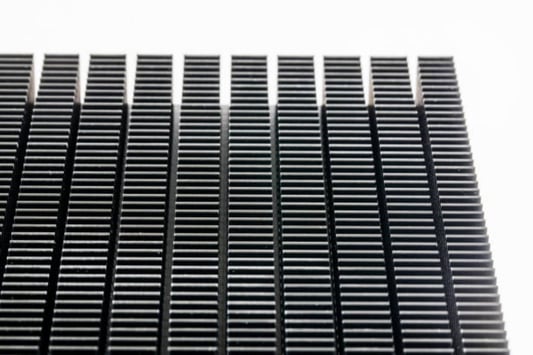

IntroductionElectronic devices generate heat as a byproduct of their operations. This heat, if not dissipated efficiently, can damage the device and even cause malfunctions. That's where an electronic heat sink comes into play. In this article, we'll discuss what an electronic heat sink is, how it works, and its different types.What Is an Electronic Heat Sink?An electronic heat sink is a component that helps dissipate heat generated by electronic devices, such as transistors, CPUs, and GPUs. It usually consists of a metallic or ceramic material with a large surface area exposed to the surrounding air or a cooling medium, such as water or liquid nitrogen. The goal is to transfer the heat from the device to the heat sink and then to the environment, where it can be dissipated without causing damage to the electronic components.How Does an Electronic Heat Sink Work?When an electronic device generates heat, it raises the temperature of the surrounding air or the medium in contact with it. This temperature difference creates a gradient that drives the heat flow from the device to the heat sink. The heat sink, in turn, spreads the heat over its surface area, maximizing the contact area with the environment and promoting convective, conductive, and sometimes radiative heat transfer. The shape, size, and material of the heat sink can influence its thermal performance.Types of Electronic Heat SinksThere are several types of electronic heat sinks available, each with its design and application. The most common ones include:Finned Heat SinkA finned heat sink is a heat sink with fins that increase the surface area for heat dissipation. The fins can be straight, curved, or pin-shaped, and they usually extend perpendicular to the heat sink's base. This type of heat sink is suitable for devices that generate moderate to high amounts of heat, such as CPUs and power transistors.Liquid-Cooled Heat SinkA liquid-cooled heat sink uses a liquid, such as water or coolant, to circulate through a network of channels inside the heat sink. The liquid absorbs the heat from the device and then transfers it to a radiator or a heat exchanger, where it can be dissipated to the environment. This type of heat sink can achieve higher thermal performance than finned heat sinks but requires additional components, such as a pump and tubing.Thermoelectric Heat SinkA thermoelectric heat sink, also known as a Peltier cooler, uses the Peltier effect to create a temperature gradient between two sides of a semiconducting material. One side of the material absorbs heat from the device and gets colder, while the other side releases the heat and gets hotter. This type of heat sink can achieve very low temperatures but also consumes more energy than other types.Heat Pipe Heat SinkA heat pipe heat sink uses a sealed pipe filled with a working fluid, such as water or alcohol, to transfer heat from the device to the heat sink's fins or base. The working fluid evaporates on the hot side and condenses on the cold side, effectively transporting heat with minimal thermal resistance. This type of heat sink can work in any orientation and is suitable for devices that generate heat in a localized area.Natural Convection Heat SinkA natural convection heat sink relies on the natural flow of air due to temperature differences to dissipate heat. It usually has a simple design with few fins or ridges and works well for low-power devices or in environments with sufficient airflow. However, it may not be efficient enough for high-power devices that require active cooling.ConclusionAn electronic heat sink is an essential component to prevent electronic devices from overheating and malfunctioning. There are different types of electronic heat sinks available, each with its design and application, depending on the device's thermal requirements and the environment's cooling conditions. Choosing the right heat sink can improve the device's performance, reliability, and lifespan.Quote InquiryContact us!