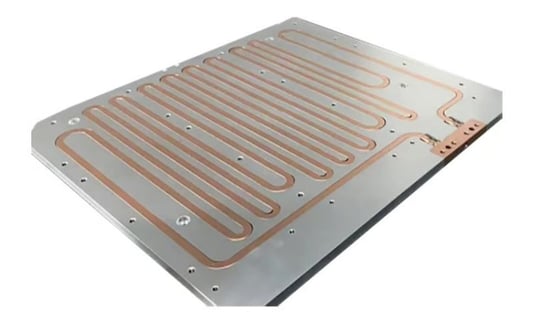

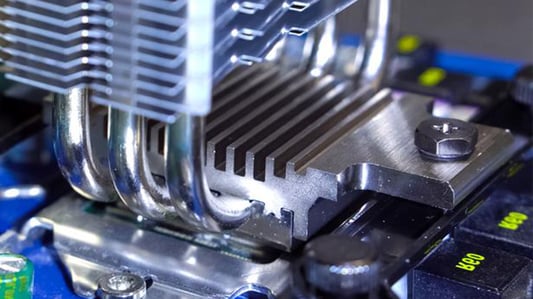

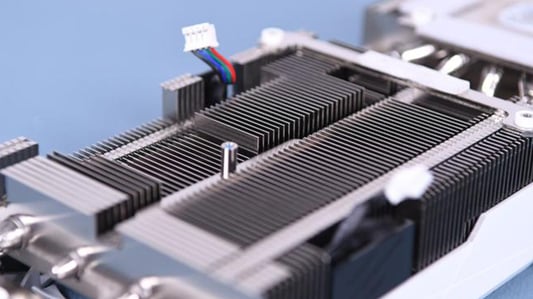

The Advantages and Applications of liquid cold plates Liquid cooling is a vital component in modern electronic devices that generate a lot of heat. One of the key elements of liquid cooling is the liquid cold plate. These plates offer numerous benefits over traditional air cooling systems and can be used in various applications. In this article, we'll explore the advantages and various applications of liquid cold plates. What are Liquid Cold Plates? Liquid cold plates are heat exchangers that transfer heat generated by electronic devices to a liquid cool. The devices are mounted on the plates, which have channels that allow the fluid to flow through the plates. Liquid cooling is a more efficient and practical way to cool electronic devices that generate a lot of heat than traditional air cooling systems. The Advantages of Liquid Cold Plates Liquid cold plates offer several advantages over traditional air cooling systems. Some of the benefits include:Improved heat transfer efficiencyReduced noise levelsIncreased system reliability and lifespanHigher power densityApplications of Liquid Cold Plates Liquid cold plates are used in various applications that require efficient cooling of electronic devices. Some of the common applications include:Power electronicsLaser diodesEV chargingSolar technologyMedical devicesLiquid Cold Plates for Power Electronics Power electronics is a rapidly growing industry that requires efficient cooling of high-powered electronic devices. Liquid cooling is an ideal solution for this application, as it offers increased power density, reduced noise levels, and improved reliability. Liquid cold plates are commonly used in high-performance computing, electric vehicles, and data centers. Liquid Cold Plates for Laser Diodes Laser diodes are high-powered devices that generate a lot of heat, and efficient cooling is necessary for their proper functioning. Liquid cooling is an ideal solution for this application, as it offers improved heat dissipation and temperature control. Liquid cold plates are commonly used in industrial lasers, medical lasers, and scientific research applications. Liquid Cold Plates for EV Charging Stations Electric vehicle (EV) charging stations require efficient cooling of high-powered components such as power modules and connectors. Liquid cooling is an ideal solution for this application, as it offers improved efficiency and reliability. Liquid cold plates are commonly used in DC fast chargers, which require efficient cooling for quick charging. Liquid Cold Plates for Solar Technology Solar technology requires efficient cooling of electronic devices such as solar inverters. Liquid cooling is an ideal solution for this application, as it offers improved temperature control and increased power density. Liquid cold plates are commonly used in commercial and utility-scale solar installations. Liquid Cold Plates for Medical Devices Medical devices such as magnetic resonance imaging (MRI) machines require efficient cooling of electronic components to maintain safe and reliable operation. Liquid cooling is an ideal solution for this application, as it offers improved temperature control and reliability. Liquid cold plates are commonly used in medical imaging equipment, surgical lasers, and other medical devices. Conclusion Liquid cold plates are an essential component in modern electronic devices that require efficient cooling. They offer several benefits over traditional air cooling systems, including improved efficiency, reliability, and power density. Liquid cold plates are used in various applications, including power electronics, laser diodes, EV charging, solar technology, and medical devices.