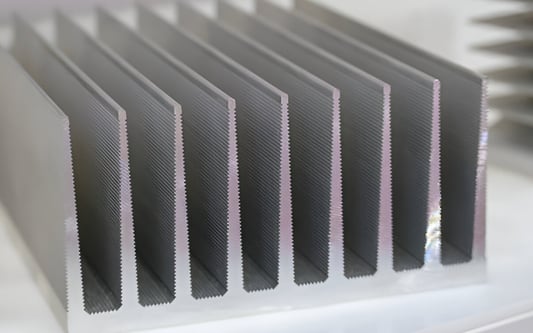

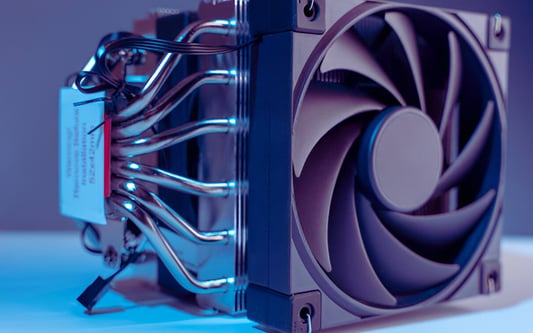

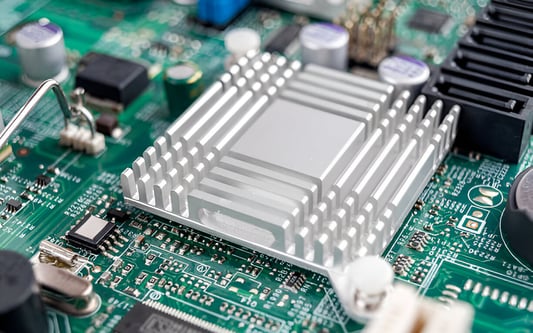

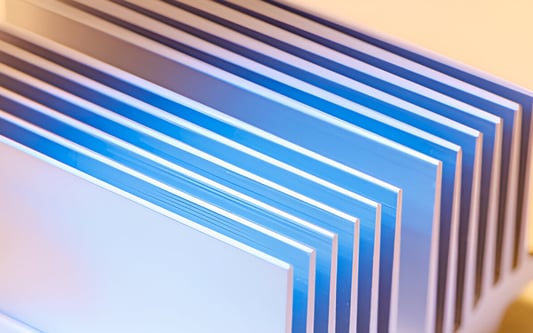

Understanding Stamped Heat SinkWhen it comes to managing heat in electronic applications, heat sinks are an essential component. A heat sink is a heat exchange component that removes heat from an electronic device that could otherwise cause damage. Stamped heat sinks are a type of heat sink designed for effective heat dissipation in electronics. This article provides comprehensive information on what stamped heat sinks are, how they work, and their benefits.What is a Stamped Heat Sink?Stamped heat sinks are heat sinks that are produced through a stamping process. This manufacturing process involves creating a heat sink by stamping it out of a large piece of metal foil. Stamped heat sinks are commonly used in electronic devices due to their high efficiency in heat dissipation.How are Stamped Heat Sinks Made?The stamping process involves the use of a stamping press that punches or dies a heat sink design into a piece of metal foil. The foil is then cut and formed into the desired shape. Stamped heat sinks are often made from aluminum or copper because they are good conductors of heat.Benefits of Stamped Heat SinksStamped heat sinks have several benefits that make them an attractive option in electronic devices. Firstly, they are cost-effective due to their high-speed, low-cost stamping method. Secondly, they are lightweight and compact, making them ideal for devices with limited space. Lastly, stamped heat sinks are highly customizable, meaning that they can be designed to meet specific requirements.How Do Stamped Heat Sinks Work?The primary function of a stamped heat sink is to transfer heat from a high-temperature object to a cooler environment. Stamped heat sinks do this by creating a thermal bridge between a hot device and the surrounding air, which allows heat to flow from the device to the heat sink, and then to the environment.Types of Stamped Heat SinksThere are several types of stamped heat sinks available that differ in design and application. The most common types include straight fin, angle fin, cross-cut, and elliptical fin stamped heat sinks. Each type of stamped heat sink has its own unique properties and is used in different applications.Applications of Stamped Heat SinksStamped heat sinks are used in various electronic devices such as computers, smartphones, medical equipment, and power supplies. They are also used in automotive and aerospace applications due to their high efficiency in dissipating heat.Comparing Stamped Heat Sinks with Other Heat Sink TypesStamped heat sinks have several advantages over other heat sink types. For instance, they have a lower thermal resistance, making them more efficient in dissipating heat than extruded heat sinks. Secondly, they offer faster production speeds and higher tooling flexibility than cast heat sinks.Choosing the Right Stamped Heat SinkWhen selecting a stamped heat sink, several factors should be considered, including the thermal design of the application, the size and shape required and the materials used. It is also essential to consider the application, including the heat source, airflow, and temperature and humidity requirements.The Bottom LineIn conclusion, stamped heat sinks are an efficient and cost-effective way to manage heat in electronic devices. They are customizable, lightweight, and compact, making them ideal for a wide range of devices. When selecting a stamped heat sink, it is essential to consider the application, thermal design, and size and materials required.Quote InquiryContact us