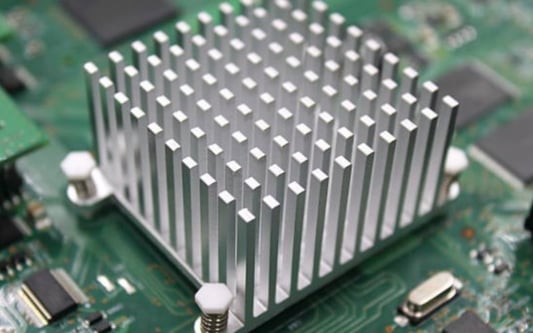

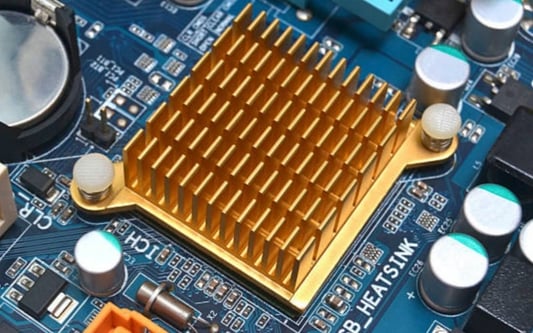

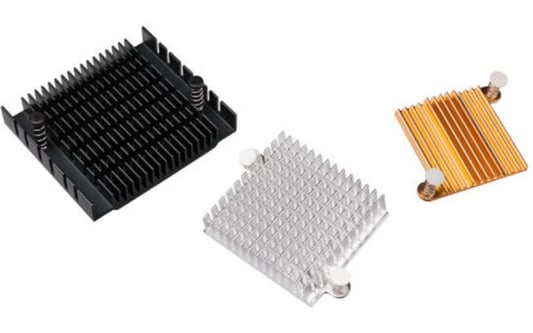

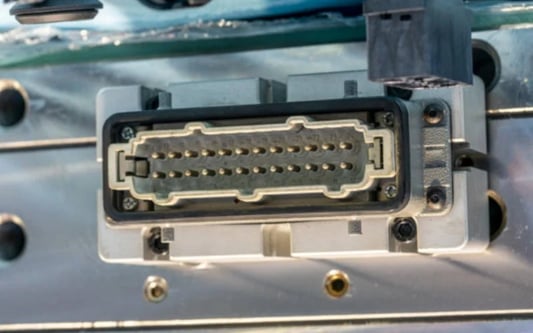

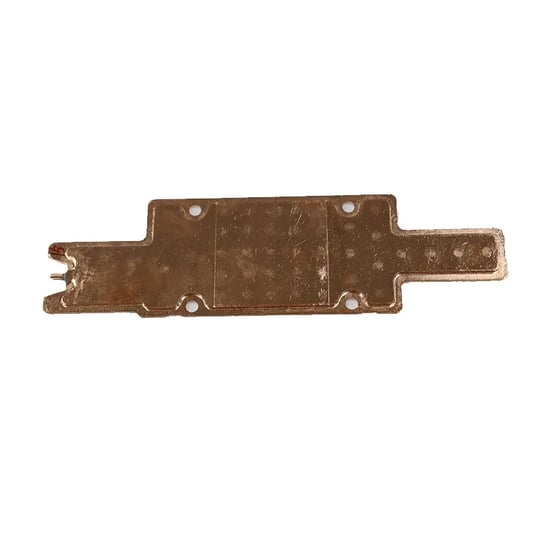

The Importance of copper cold plate for Electronic DevicesIn the electronics industry, components such as CPUs and GPUs need to be kept at a low temperature to prevent malfunction. This is where copper cold plate comes in, as it is an efficient and reliable way of dissipating heat. Copper is an ideal material for cold plates because it has excellent thermal conductivity, good mechanical strength, and is resistant to corrosion. In this article, we will discuss the advantages and applications of copper cold plates.1. Excellent Thermal ConductivityCopper has the highest thermal conductivity among non-precious metals, making it an ideal material for heat dissipation. When heat is transferred to the cold plate, copper quickly conducts it away from the source, distributing it evenly across the entire plate. This results in a more efficient cooling process and prevents the device from overheating.2. Cold Plate DesignThe design of the cold plate also plays a significant role in its cooling efficiency. The most common design is a flat cold plate with microchannels, which increases the surface area for heat dissipation. This design allows for a more even temperature distribution across the entire cold plate surface, further preventing hotspots and consequent device damage.3. Good Mechanical StrengthCopper is not only a good heat conductor but also has excellent mechanical strength. This feature is crucial in preventing the cold plate from cracking or breaking under pressure. The copper cold plate can withstand high pressures, making it suitable for use in high-performance electronic devices.4. Resistant to CorrosionCopper is resistant to corrosion, which protects the cold plate from degrading over time. Corrosion can cause the cold plate to lose its effectiveness, particularly when used in extreme environments. Due to its corrosion resistance, copper cold plates tend to have a longer lifespan than other materials, providing long-lasting protection against heat damage.5. Applications of Copper Cold PlateCopper cold plate is used in various industries, including:Computer systemsPower electronicsAutomotive industryAerospace applicationsMedical equipment6. Computer SystemsCopper cold plates are widely used in computer systems, particularly in high-performance servers, desktop computers, and gaming computers that generate a lot of heat. They are also used in cryptocurrency mining rigs that require constant cooling to operate efficiently.7. Power ElectronicsPower electronics such as AC drives, inverters, and rectifiers generate a significant amount of heat, which can damage the device if not managed effectively. Copper cold plates are used to provide a reliable and efficient cooling solution in various power electronic devices.8. Automotive IndustryThe automotive industry uses copper cold plates in hybrid or electric vehicles, where efficient cooling of the battery pack is critical to avoid overheating and damage. Copper cold plates are also used in heat exchangers and oil coolers.9. Aerospace ApplicationsIn the aerospace industry, copper cold plates are used in satellite thermal control and rocket engine cooling systems. Cold plates provide a reliable and efficient cooling solution in high-temperature environments, protecting the sensitive components of the spacecraft and rocket engines.10. Medical EquipmentCopper cold plates are used in medical equipment, particularly in MRI machines that generate a significant amount of heat. Sensitive components, such as the magnet coils, require efficient cooling to avoid overheating and damage.ConclusionCopper cold plates are an essential component in the electronics industry, providing reliable and efficient cooling to prevent devices from overheating and damaging sensitive components. Their excellent thermal conductivity, good mechanical strength, and resistance to corrosion make copper cold plates a reliable choice for cooling solutions in various industries.Quote InquiryContact us!