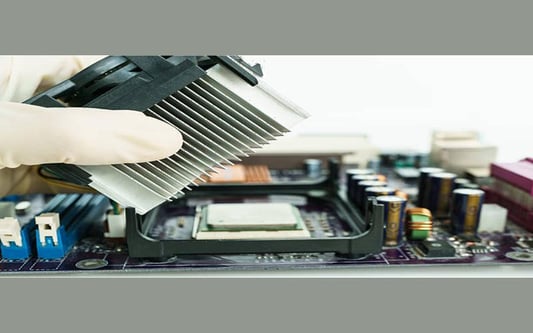

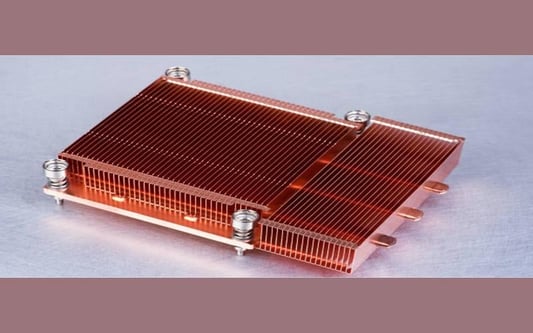

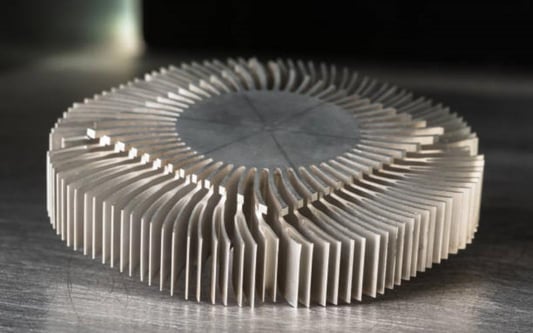

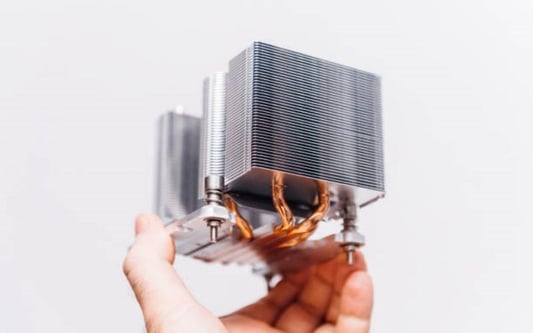

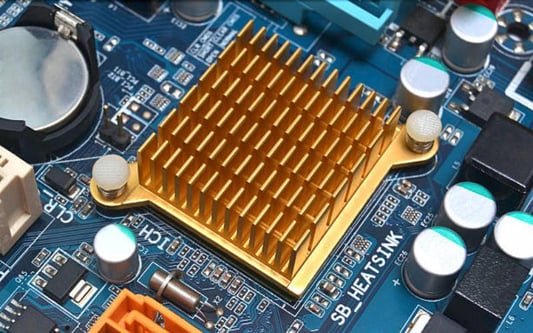

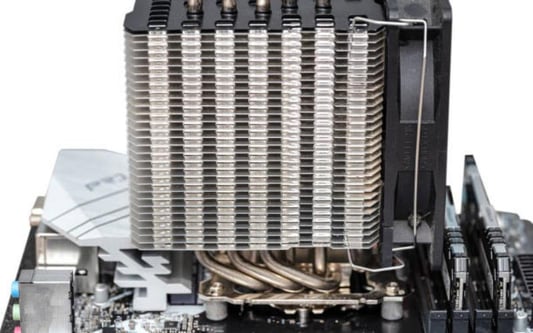

What are Heat Sinks in Electronics?Heat sinks play a crucial role in the world of electronics. They are essential components that help manage and dissipate heat generated by electronic devices. In this article, we will explore the various aspects of heat sinks, their importance, and how they work to prevent overheating in electronic systems.The Basics of Heat SinksHeat sinks are passive cooling devices designed to absorb and dissipate heat generated by electronic components. They are commonly made of materials with high thermal conductivity, such as aluminum or copper, to efficiently transfer heat away from the source.How Do Heat Sinks Work?Heat sinks work based on the principle of conduction and convection. When an electronic component generates heat, the heat is conducted through the component and transferred to the heat sink. The heat sink then dissipates the heat into the surrounding environment through convection.The Importance of Heat Sinks in ElectronicsHeat sinks are crucial in electronic devices as they help prevent overheating, which can lead to reduced performance, component failure, or even permanent damage. By efficiently dissipating heat, heat sinks ensure that electronic components operate within their safe temperature limits, allowing for optimal performance and longevity.Types of Heat SinksThere are various types of heat sinks available, each designed for specific applications and cooling requirements. Some common types include:1. Finned Heat Sinks:Finned heat sinks are the most commonly used type. They feature a series of thin fins that increase the surface area, allowing for better heat dissipation. The increased surface area facilitates greater contact with the surrounding air, improving cooling efficiency.2. Fan-cooled Heat Sinks:Fan-cooled heat sinks incorporate a fan to enhance the airflow and improve heat dissipation. These heat sinks are ideal for situations where passive cooling alone is insufficient to handle the heat generated by the electronic component.3. Liquid-cooled Heat Sinks:Liquid-cooled heat sinks use a liquid, such as water or coolant, to transfer and dissipate heat. They are highly efficient and commonly found in high-performance electronic systems, such as gaming PCs or data centers.Factors Affecting Heat Sink PerformanceSeveral factors influence the performance of heat sinks:1. Thermal Conductivity:The thermal conductivity of the heat sink material determines how effectively it transfers heat. Materials with higher thermal conductivity, such as copper, are more efficient at dissipating heat than those with lower thermal conductivity.2. Surface Area:The surface area of the heat sink directly affects its cooling capacity. Heat sinks with larger surface areas allow for better heat dissipation and can handle higher thermal loads.3. Airflow:Adequate airflow is crucial for effective heat dissipation. Heat sinks should be designed to maximize airflow across their fins or use fans to ensure proper cooling.4. Mounting and Contact:The proper mounting and contact between the heat sink and the electronic component are essential for efficient heat transfer. The use of thermal interface materials, such as thermal paste or pads, helps improve contact and minimize thermal resistance.ConclusionHeat sinks are vital components in the field of electronics. They prevent overheating, ensure optimal performance, and enhance the longevity of electronic devices. Understanding the different types of heat sinks and the factors affecting their performance can help engineers and designers make informed decisions when it comes to cooling electronic systems.Quote Inquiry