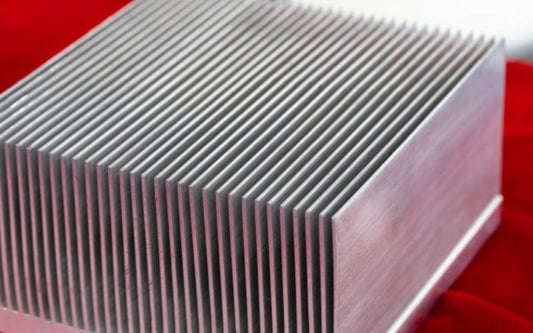

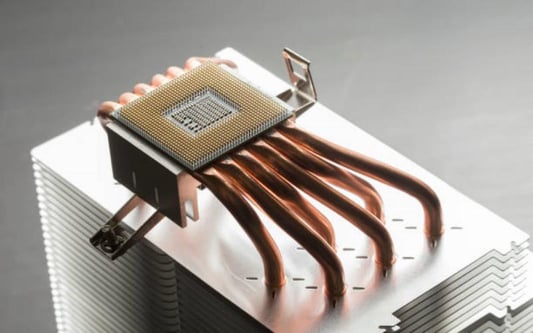

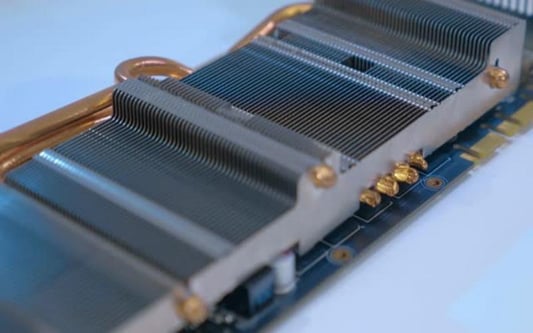

IntroductionHeat pipes are widely used in various industries for their efficient heat transfer capabilities. They are passive heat transfer devices that can transport heat from one location to another with minimal temperature difference. In this article, we will explore the different Types of Heat Pipes and their applications. Whether you are an engineer, researcher, or simply curious about heat pipes, this comprehensive guide will provide you with valuable insights.1. Copper Heat PipesCopper heat pipes are one of the most common types of heat pipes used in many applications. Copper has excellent thermal conductivity, making it an ideal material for heat pipes. These heat pipes are often used in electronics cooling, where high heat transfer rates are required. Copper heat pipes can efficiently dissipate heat from electronic components and maintain temperature stability.2. Aluminum Heat PipesAluminum heat pipes are another popular choice, especially for lightweight applications. Aluminum is lightweight and has good thermal conductivity, making it suitable for heat pipe manufacturing. These heat pipes are commonly used in cooling systems for laptops, LED lights, and other portable devices. Aluminum heat pipes offer a balance between performance and weight, making them a preferred choice in many applications.3. Loop Heat PipesLoop heat pipes (LHPs) are a type of heat pipe that utilizes a wick structure to transport the working fluid. Unlike traditional heat pipes, LHPs can operate against gravity and transport heat over long distances. They are often used in aerospace and satellite applications where heat needs to be dissipated from sensitive electronic components. LHPs offer excellent thermal management capabilities in challenging environments.4. Thermosyphon Heat PipesThermosyphon heat pipes are passive heat transfer devices that rely on the natural convection process. They consist of an evaporator section, where heat is absorbed, and a condenser section, where heat is dissipated. Thermosyphon heat pipes are commonly used in solar water heaters, air conditioning systems, and other applications where natural convection can be utilized for heat transfer.5. Sodium Heat PipesSodium heat pipes are a specialized type of heat pipe that uses sodium as the working fluid. Sodium has a low melting point and high thermal conductivity, making it suitable for high-temperature applications. Sodium heat pipes are often used in nuclear reactors, advanced power generation systems, and other high-temperature environments where conventional heat pipes may not be suitable.6. Variable Conductance Heat PipesVariable conductance heat pipes (VCHPs) are heat pipes that can adjust their thermal conductance based on the heat load. They are designed to provide effective cooling in applications with varying heat loads. VCHPs are commonly used in electronics cooling, where the heat dissipation requirements can vary depending on the workload. These heat pipes offer flexibility and efficient thermal management.7. Vapor Chamber Heat PipesVapor chamber heat pipes are two-dimensional heat pipes that are often used in electronic devices with high power densities. They consist of a flat plate with a wick structure and a working fluid. Vapor chamber heat pipes can efficiently spread heat in devices such as CPUs, GPUs, and LED panels. They offer superior thermal conductivity and enable uniform temperature distribution.8. Micro Heat PipesMicro heat pipes are miniature heat pipes with diameters ranging from a few millimeters to sub-millimeter sizes. They are commonly used in compact electronic devices where space is limited. Micro heat pipes can provide efficient cooling in small form factor devices such as smartphones, tablets, and wearables. These heat pipes enable effective heat dissipation in confined spaces.9. Capillary Pumped Heat PipesCapillary pumped heat pipes (CPHPs) are heat pipes that use capillary action to circulate the working fluid. They have a wick structure that facilitates the movement of the working fluid from the condenser to the evaporator section. CPHPs are often used in aerospace applications, where reliable heat transfer is essential. They offer high heat transfer rates and are resistant to gravitational forces.10. Applications of Heat PipesHeat pipes find applications in a wide range of industries, including electronics cooling, aerospace, automotive, power generation, and more. They are used in heat sinks, thermal management systems, heat exchangers, and other cooling devices. Heat pipes play a crucial role in enhancing the efficiency and reliability of various systems, ensuring optimal thermal performance.ConclusionTypes of heat pipes discussed in this article offer diverse solutions for efficient heat transfer in various applications. Whether it is copper heat pipes for electronics cooling, loop heat pipes for aerospace, or vapor chamber heat pipes for high-power electronic devices, each type has its unique advantages. Understanding the different types of heat pipes and their applications can help engineers and researchers make informed decisions when designing thermal management systems.Quote Inquiry