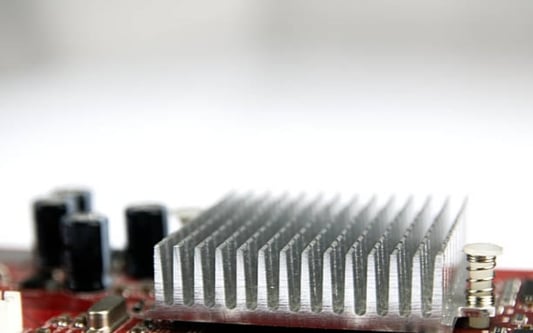

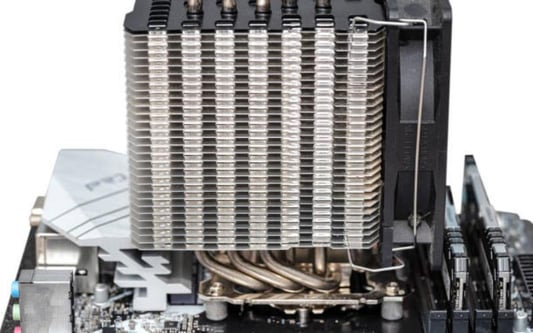

The Basics of Heat SinksHeat sinks are essential components in many electronic devices, helping dissipate excess heat and maintain optimal operating temperatures. They come in various types and designs, but in this article, we will focus on the two main categories of heat sinks: active and passive. Understanding the differences between these two types can help you make informed decisions when it comes to choosing the right heat sink for your specific needs.1. Active Heat Sinks: Keeping It Cool with FansActive heat sinks, as the name suggests, actively enhance heat dissipation by utilizing fans or blowers. These heat sinks are commonly seen in devices that generate a significant amount of heat, such as high-performance CPUs and graphics cards. The main advantage of active heat sinks is their ability to provide efficient cooling even in demanding conditions.These heat sinks often consist of a metal base to absorb heat from the heat-generating component and heat pipes or fins to dissipate the heat. The fan or blower mounted on the heat sink increases the airflow, accelerating the heat transfer process. Active heat sinks are particularly effective in situations where passive cooling alone may not be sufficient.2. Passive Heat Sinks: Silent and Reliable CoolingPassive heat sinks, on the other hand, do not rely on any external mechanisms like fans to dissipate heat. Instead, they rely solely on natural convection, conduction, and radiation to transfer heat away from the source. These heat sinks are commonly found in devices where noise reduction and reliability are paramount.Passive heat sinks are typically made of metal, such as aluminum or copper, which have high thermal conductivity. The design of passive heat sinks includes fins or ridges that increase the surface area for better heat dissipation. As the heat is conducted through the base, it is gradually dissipated to the surrounding air.Choosing the Right Heat SinkWhen selecting a heat sink for your application, several factors should be considered. The power dissipation of the component, available space, airflow conditions, and noise requirements all play a significant role in determining the appropriate heat sink type.If your device operates in a confined space or requires silent operation, a passive heat sink might be the better choice. On the other hand, if your device generates a substantial amount of heat and has enough space for a fan, an active heat sink can provide superior cooling performance.Benefits and LimitationsBoth active and passive heat sinks offer unique benefits and limitations:Benefits of Active Heat Sinks:Efficient cooling in high-power applicationsEnhanced heat dissipation with the help of fansEffective in confined spaces with limited airflowLimitations of Active Heat Sinks:Noisy operation due to fan or blowerHigher power consumptionBenefits of Passive Heat Sinks:Silent operationNo power consumptionReliable and maintenance-freeLimitations of Passive Heat Sinks:Less effective in high-power applicationsRequires sufficient airflow and spaceIn ConclusionHeat sinks are vital components in many electronic devices, and understanding the different types available is crucial for optimal thermal management. Active heat sinks excel in high-power applications and limited airflow environments, while passive heat sinks are ideal for silent operation and reliability. Consider the specific requirements of your device and make an informed decision to ensure efficient heat dissipation and prolonged device lifespan.Quote InquiryContact us!