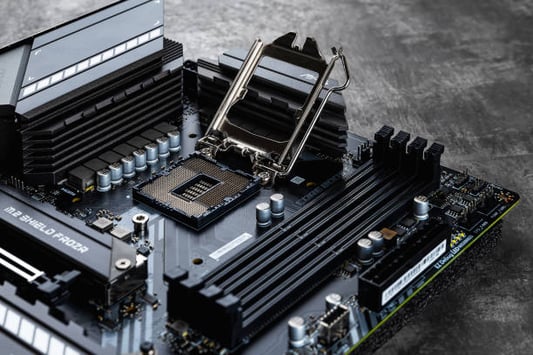

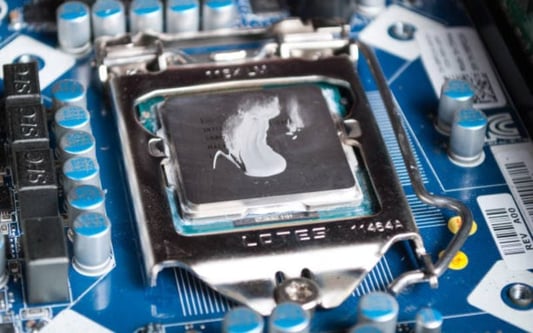

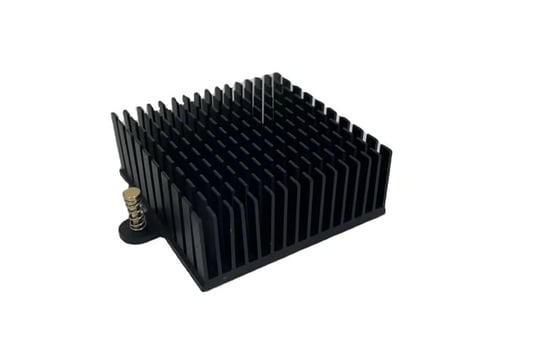

Do CPU coolers come with a heat sink??For those who are building a PC for the first time, there are many components to consider. One of the most important is the CPU cooler, which is responsible for maintaining safe temperatures for your CPU. One of the questions we hear frequently is, "Do CPU coolers come with a heat sink?" In this article, we'll explore this question in depth and provide useful information about what you need to know when choosing a CPU cooler.What is a heat sink?A heat sink is an essential component of a CPU cooler. It is a metal component that is attached to the CPU and is responsible for dissipating heat away from the CPU. It absorbs heat from the CPU and transfers it to the cooler's fins, which then diffuse the heat into the air. Without a heat sink, CPUs would overheat quickly and sustain damage.What is a CPU cooler?A CPU cooler is made up of several components, but the two most critical are the heat sink and the fan. The heat sink absorbs heat from the CPU, and the fan then moves air across the heat sink to cool it down. Other components include mounting hardware, thermal paste, and additional heat pipes that help move heat away from the CPU. Together, these components make up a CPU cooling system.Types of CPU coolersThere are many different types of CPU coolers to choose from, but they all fall into two main categories: air coolers and liquid coolers. Air coolers are the most common type of CPU cooler and use fans to move air across the heat sink. Liquid coolers are more complicated and use water to move heat away from the CPU. They typically require more installation work than air coolers and can be more expensive, but they can also provide better cooling performance.Do all CPU coolers come with a heat sink?The short answer is yes. All CPU coolers, whether they are air coolers or liquid coolers, come with a heat sink. It is an essential component of any CPU cooling system and cannot be omitted. Some high-end CPU coolers may have multiple heat sinks or larger heat sinks, but they all have at least one heat sink.Are all heat sinks the same?No, not all heat sinks are created equal. There are many factors to consider when choosing a heat sink, such as size, shape, the material it is made from, and the number of heat pipes it has. The quality and performance of a heat sink can vary greatly depending on these factors.Can you replace a heat sink?Yes, it is possible to replace a heat sink. If you are experiencing high CPU temperatures or want to upgrade to a better performing heat sink, you can remove your existing heat sink and replace it with a new one. Some CPU coolers come with additional heat sink options so that you can upgrade later without having to replace the entire cooler.What is thermal paste, and do I need to use it?Thermal paste is a viscous material that is applied to the top of the CPU before attaching the heat sink. It helps to fill in any uneven areas on the surface of the CPU and ensures maximum contact between the CPU and the heat sink. It is essential to use thermal paste when installing a new heat sink to ensure that heat is transferred efficiently. Most CPU coolers come with thermal paste included, but you can also purchase it separately.What should I look for when choosing a CPU cooler?When choosing a CPU cooler, there are several essential factors to consider. The first is compatibility with your CPU socket, as not all CPU coolers will fit every socket type. You also need to consider the size of your case and ensure that the cooler you choose will fit in it. Additionally, you will want to consider the cooling performance, noise level, and aesthetics of the cooler.Do I need to clean my heat sink?Yes, it is essential to keep your heat sink clean to ensure that it functions correctly. Over time, dust and debris can accumulate on the heat sink, which can reduce its cooling performance. You can clean your heat sink by blowing compressed air across the fins or using a specialized cleaner. It's generally a good idea to clean your heat sink once a year or more often if you live in a dusty environment.ConclusionChoosing the right CPU cooler with a heat sink is essential for keeping your computer running at optimal temperatures. All CPU coolers come with a heat sink, and it is an integral part of any cooling system. By considering the factors we've discussed in this article, you'll be able to choose the right CPU cooler for your needs and keep your PC running smoothly for years to come.Quote InquiryContact us!