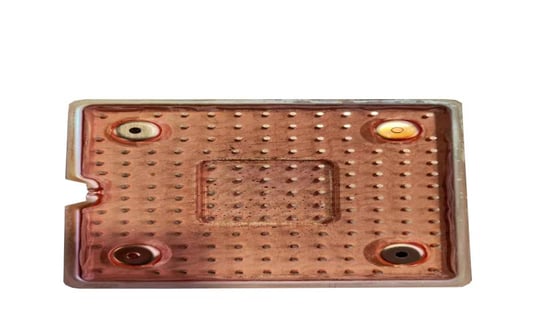

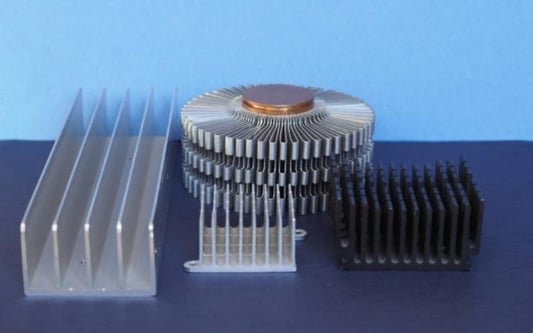

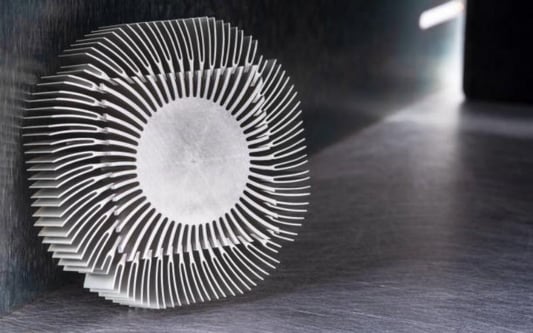

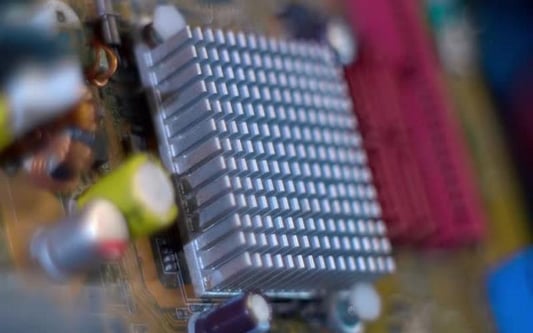

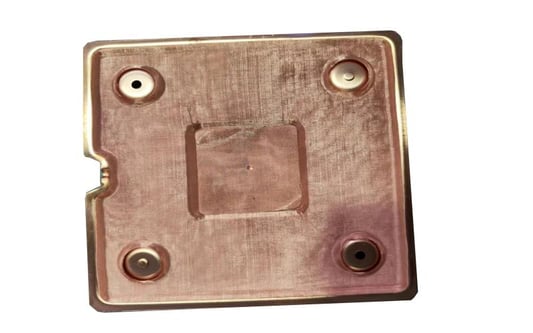

The Difference Between a Cold Plate and a Heat Sink: ExplainedIntroduction: Understanding Cooling TechnologiesCold plates and heat sinks are two common cooling technologies used in various industries to dissipate heat. While both serve the purpose of cooling electronic components, they have distinct differences in design, functionality, and applications. In this article, we will explore the dissimilarities between cold plates and heat sinks, shedding light on their unique characteristics and how they contribute to efficient heat management.1. Cold Plates: Efficient Heat Transfer Through Direct ContactCold plates are cooling devices that utilize direct contact between the cooling medium and the heat source to transfer heat efficiently. They are typically made of thermally conductive materials, such as aluminum or copper, and are designed to provide a large surface area for effective heat dissipation.2. Heat Sinks: Passive Cooling through ConvectionHeat sinks, on the other hand, are passive cooling devices that rely on convection to dissipate heat. They are often made of aluminum or copper and feature fins or other extended surfaces to increase the surface area available for heat transfer. Heat sinks work by utilizing the airflow created by fans or natural convection to carry away heat from the component.3. Design and Construction: Differences in StructureWhen it comes to design and construction, cold plates and heat sinks exhibit notable differences. Cold plates are typically flat, with grooves or channels to allow the cooling medium, such as liquid coolant or refrigerant, to flow through. This direct contact with the heat source ensures efficient heat transfer. Heat sinks, on the other hand, have a finned structure that maximizes the surface area exposed to the surrounding air, enhancing heat dissipation through convection.4. Cooling Mechanism: Direct vs. IndirectOne of the key distinctions between cold plates and heat sinks lies in their cooling mechanisms. Cold plates achieve cooling through direct contact with the heat source, which enables rapid heat transfer. The cooling medium absorbs the heat and carries it away, ensuring efficient cooling. In contrast, heat sinks rely on the surrounding air or a forced airflow to remove heat from the component. The fins on the heat sink facilitate heat dissipation by increasing the surface area available for convection.5. Applications: Where Cold Plates ExcelCold plates are commonly used in applications where direct cooling is required, especially in scenarios where high heat fluxes need to be managed effectively. They find extensive use in power electronics, laser diodes, high-performance CPUs, and other components that generate significant heat. Cold plates are particularly beneficial in situations where liquid cooling is necessary or preferred over air cooling.6. Applications: Where Heat Sinks ShineHeat sinks, on the other hand, are widely employed in electronic devices and systems that require passive cooling. They are commonly found in computers, LED lighting, telecommunications equipment, and various consumer electronics. Heat sinks are effective in dissipating moderate heat loads and are often integrated with fans or other cooling mechanisms to enhance their cooling capacity.7. Heat Dissipation Capacity: Comparing PerformanceWhen it comes to heat dissipation capacity, the choice between a cold plate and a heat sink depends on the specific cooling requirements of the application. Cold plates excel in managing high heat fluxes and can effectively handle heat loads of several hundred watts. Heat sinks, on the other hand, are more suitable for moderate heat loads and are capable of dissipating heat in the range of tens to a few hundred watts.8. Thermal Resistance: Minimizing Heat Transfer BarriersThermal resistance is an important factor to consider when evaluating the performance of cooling technologies. Cold plates typically have lower thermal resistance due to their direct contact with the heat source, enabling efficient heat transfer. Heat sinks, although they have higher thermal resistance compared to cold plates, can still provide adequate cooling for many applications when properly designed and optimized.9. Size and Form Factor: Compactness vs. CustomizationCold plates and heat sinks also differ in terms of size and form factor. Cold plates generally have a larger footprint due to the need for direct contact with the heat source and the space required for the cooling medium flow. Heat sinks, on the other hand, can be more compact and versatile in terms of shape and size. They can be custom-designed to fit specific components or space limitations.10. Cost Considerations: Balancing Efficiency and BudgetCost is a crucial factor in selecting between cold plates and heat sinks. Cold plates, especially those utilizing liquid cooling, tend to be more expensive due to the complexity of their design and the additional components required (such as pumps and tubing). Heat sinks, being passive cooling solutions, are generally more cost-effective and have lower maintenance requirements.Conclusion: Choosing the Right Cooling SolutionUnderstanding the differences between cold plates and heat sinks is essential for selecting the appropriate cooling solution for your specific application. Cold plates offer efficient direct cooling, making them ideal for high heat flux scenarios, while heat sinks provide reliable passive cooling for moderate heat loads. By considering factors such as cooling requirements, thermal resistance, size constraints, and budget, you can make an informed decision and ensure effective heat management in your electronic systems.Quote InquiryFooter