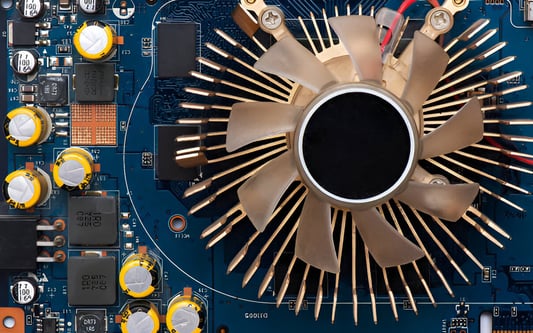

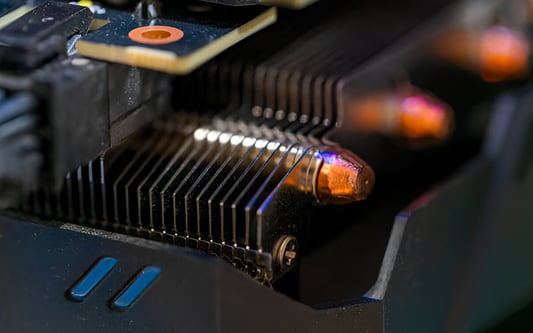

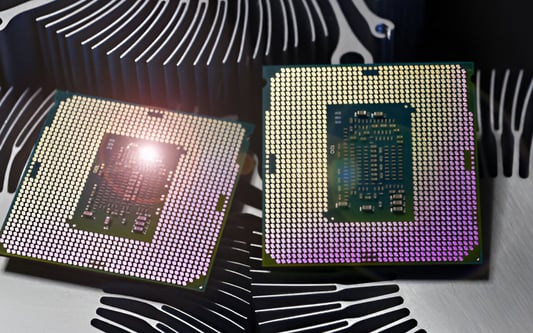

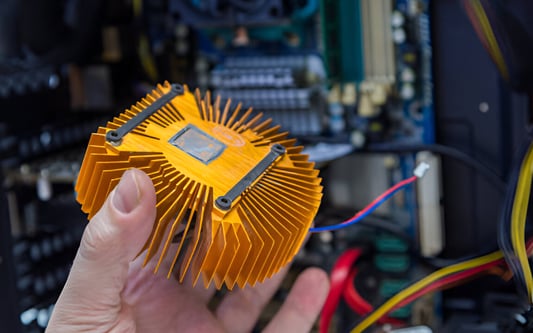

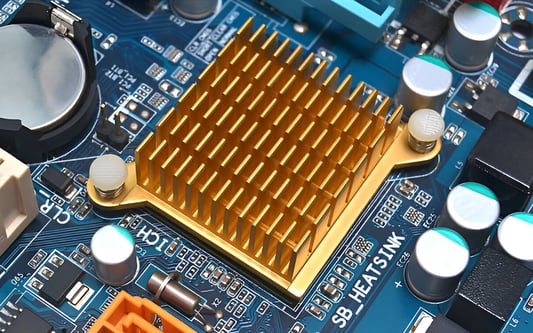

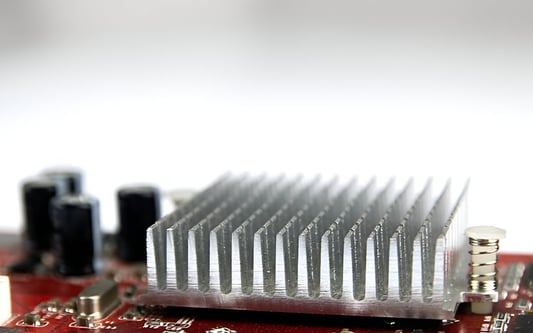

What is a round extruded aluminum heatsink?A round extruded aluminum heatsink is a component used to dissipate heat from electronic devices. It is a cylindrical structure made of aluminum that increases surface area, allowing heat to transfer more efficiently. These heatsinks come in various shapes and sizes, but round extruded aluminum heatsinks are particularly popular due to their high thermal conductivity and ease of manufacturing.How are Round Extruded Aluminum Heatsinks Made?Round extruded aluminum heatsinks are made through a process called extrusion. In this process, a mold is created in the shape of the final product and a piece of aluminum is heated until it is malleable. The aluminum is then forced through the mold, creating the desired shape. The resulting heatsink is cut to the desired length and often undergoes further processing such as anodization to improve corrosion resistance and appearance.What are the Advantages of Using Round Extruded Aluminum Heatsinks?There are several advantages to using round extruded aluminum heatsinks. Firstly, aluminum is an excellent conductor of heat, meaning that the extruded heatsink can effectively dissipate heat away from the electronic device. Secondly, round extruded aluminum heatsinks are relatively cheap and easy to manufacture, making them an attractive option for manufacturers. They are also lightweight and have a high strength-to-weight ratio, making them an ideal choice for applications where weight is a concern.What Factors Affect the Performance of a Round Extruded Aluminum Heatsink?The performance of a round extruded aluminum heatsink depends on several factors including its dimensions, material, and the airflow over the heatsink. Larger heatsinks with more surface area will generally perform better than their smaller counterparts. Heatsinks made from high-quality materials with good thermal conductivity will also perform better. Finally, the airflow over the heatsink is crucial in transferring heat away from the device. If airflow is inadequate, the heatsink will not be able to perform its job effectively.What are the Different Types of Round Extruded Aluminum Heatsinks?There are many different types of round extruded aluminum heatsinks available, each with their own unique characteristics. Some popular types include plate fin heatsinks, pin fin heatsinks, and skived heatsinks. Plate fin heatsinks are made up of several thin metal fins that run perpendicular to the base of the heatsink. Pin fin heatsinks, as the name suggests, are made up of multiple pins that protrude from the base of the heatsink. Skived heatsinks are made by slicing thin sheets of metal into thin fins, which are then bonded to a base.What Types of Electronic Devices Require Round Extruded Aluminum Heatsinks?Round extruded aluminum heatsinks are commonly used in a variety of electronic devices, including but not limited to computer CPUs, LED lighting, power amplifiers, and voltage regulators. Any electronic device that generates a significant amount of heat can benefit from the use of a heatsink.How Do You Install a Round Extruded Aluminum Heatsink?Installing a round extruded aluminum heatsink is a straightforward process. The heatsink should be mounted onto the device using a thermal interface material (TIM), which helps to transfer heat from the device to the heatsink. The TIM is generally applied between the device and the base of the heatsink before the heatsink is mounted. It is important to ensure that the heatsink is firmly attached to the device to prevent any movement that could compromise its effectiveness.Can Round Extruded Aluminum Heatsinks be Customized?Yes, round extruded aluminum heatsinks can be customized to meet the specific needs of a particular application. Custom heatsinks can be manufactured in different shapes, sizes, and materials to provide optimal thermal performance for the device in question. Additionally, heatsinks can be anodized in different colors to improve their appearance or corrosion resistance.How Do Round Extruded Aluminum Heatsinks Compare to Other Types of Heatsinks?Round extruded aluminum heatsinks are just one type of heatsink available on the market. Other popular types include copper heatsinks and heat pipes. While copper heatsinks offer better thermal conductivity than aluminum, they are also heavier and more expensive to manufacture. Heat pipes, on the other hand, are highly effective at transferring heat away from devices but are generally more expensive and complex to install. Round extruded aluminum heatsinks offer a good balance of thermal performance, cost-effectiveness, and ease of use.Where Can You Purchase Round Extruded Aluminum Heatsinks?Round extruded aluminum heatsinks can be purchased from a variety of manufacturers and suppliers. It is important to choose a reputable supplier who can provide high-quality heatsinks that are appropriate for your specific application. Some popular suppliers of round extruded aluminum heatsinks include Aavid Thermalloy, Radian Thermal Products, and Wakefield-Vette.Quote InquiryContact us