Efficiency and Performance

When it comes to heat sinks, efficiency and performance are crucial factors to consider. Stamped heat sinks are typically mass-produced and may not offer the same level of thermal conductivity as machined heat sinks. Machined heat sinks, on the other hand, are precisely crafted to maximize surface area and optimize heat dissipation, leading to better overall performance.

Cost and Production

Stamped heat sinks are generally more cost-effective to produce due to the nature of the stamping process, which allows for high-volume manufacturing. Machined heat sinks, while more expensive to produce, offer higher precision and customization options. The choice between stamped and machined heat sinks often comes down to budget constraints and specific project requirements.

Material Selection

Another key difference between stamped and machined heat sinks is the material selection. Stamped heat sinks are typically made from aluminum or copper sheets, while machined heat sinks can be crafted from a wider range of materials, including exotic alloys. The choice of material can impact the heat sink's performance, durability, and compatibility with different thermal management applications.

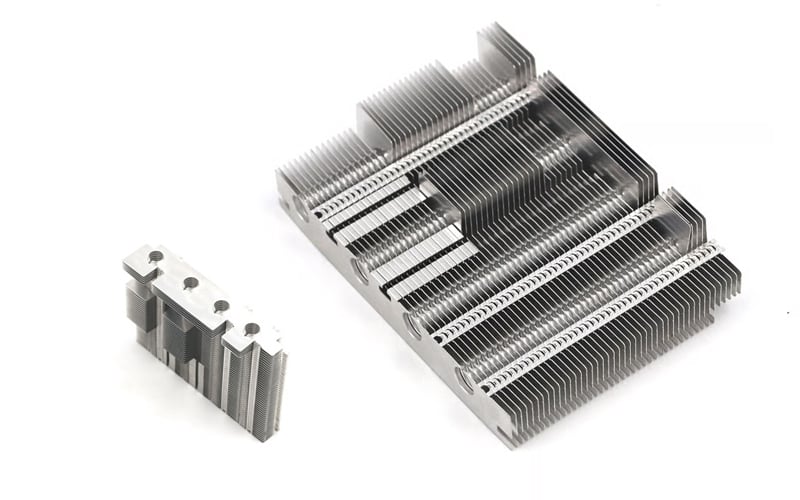

Design Flexibility

When it comes to design flexibility, machined heat sinks have the upper hand. Machining allows for intricate designs, complex geometries, and customized features that can improve thermal performance. Stamped heat sinks, while limited in design options, are suitable for simple and standard applications where customization is not a priority.

Surface Finish and Aesthetics

Stamped heat sinks often have a rougher surface finish compared to machined heat sinks, which can impact both aesthetics and functionality. Machined heat sinks can achieve smoother finishes and tighter tolerances, resulting in a more polished appearance and better overall performance. The choice between stamped and machined heat sinks may depend on the desired aesthetic and functional requirements.

Thermal Resistance

One of the key differences between stamped and machined heat sinks is thermal resistance. Machined heat sinks typically have lower thermal resistance due to their optimized design and better surface contact with the heat-generating component. Stamped heat sinks may have higher thermal resistance, which can affect their ability to effectively dissipate heat and regulate temperature.

Weight and Size

Stamped heat sinks are generally lighter and more compact than machined heat sinks, making them suitable for applications where weight and size constraints are a concern. Machined heat sinks, while heavier and bulkier, offer greater thermal performance and can accommodate larger heat loads. The choice between stamped and machined heat sinks often depends on the specific requirements of the project.

Manufacturing Lead Time

Stamped heat sinks typically have shorter manufacturing lead times compared to machined heat sinks, due to the efficiency of the stamping process. Machined heat sinks, which require more intricate machining processes, may have longer lead times but offer higher precision and customization options. The decision between stamped and machined heat sinks may be influenced by project timelines and production schedules.

Quality and Consistency

In terms of quality and consistency, machined heat sinks have the edge over stamped heat sinks. Machining allows for tighter tolerances, better control over dimensions, and higher quality finishes. Stamped heat sinks, while cost-effective, may vary in quality and consistency due to the mass-production nature of the stamping process. Choosing between stamped and machined heat sinks depends on the desired level of quality and performance.

Compatibility and Application

Finally, the choice between stamped and machined heat sinks often comes down to compatibility and application requirements. Stamped heat sinks are suitable for simple applications with lower thermal demands, while machined heat sinks are ideal for high-performance applications that require superior heat dissipation. Consider the specific requirements of your project to determine whether stamped or machined heat sinks are the best option.