Skived Heat Sink Technology is Expensive

Many people believe that skived heat sink technology is expensive due to its advanced manufacturing process and materials used. However, in reality, skived heat sinks are cost-effective compared to other types of heat sinks. The efficiency and performance of skived heat sinks make them a worthwhile investment in the long run.

Skived Heat Sink Technology is Only for High-End Applications

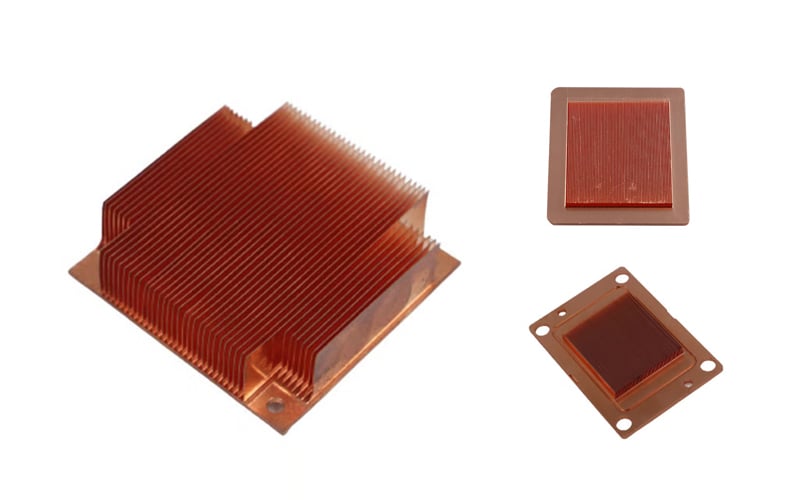

Another common misconception is that skived heat sink technology is only suitable for high-end applications. In fact, skived heat sinks are versatile and can be used in a wide range of electronic devices, from laptops to LED lighting systems. Their compact size and efficient heat dissipation make them ideal for various applications.

Skived Heat Sinks Cannot Handle High Power Levels

Some people believe that skived heat sinks are not capable of handling high power levels due to their design. However, skived heat sinks are designed to efficiently dissipate heat, making them suitable for high-power applications. With proper design and material selection, skived heat sinks can effectively manage heat even at high power levels.

Skived Heat Sink Technology is Difficult to Customize

There is a misconception that skived heat sink technology is difficult to customize to meet specific requirements. On the contrary, skived heat sinks are highly customizable in terms of shape, size, and thermal performance. Manufacturers can tailor skived heat sinks to meet the unique needs of different electronic devices.

Skived Heat Sinks Have Limited Thermal Conductivity

Some people mistakenly believe that skived heat sinks have limited thermal conductivity compared to other heat sink technologies. In reality, skived heat sinks have excellent thermal conductivity due to their optimized design and manufacturing process. They are capable of efficiently transferring heat away from electronic components.

Skived Heat Sink Technology is Not Reliable

Another misconception is that skived heat sink technology is not reliable and may not provide consistent cooling performance. However, skived heat sinks undergo rigorous testing and quality control measures to ensure reliability. When properly designed and manufactured, skived heat sinks can maintain optimal thermal performance over time.

Skived Heat Sinks are Prone to Corrosion

Some people believe that skived heat sinks are prone to corrosion, especially in harsh environments. While certain materials used in skived heat sinks may be susceptible to corrosion, proper coatings and materials selection can mitigate this issue. Skived heat sinks can be designed to withstand challenging operating conditions.

Skived Heat Sink Technology is Obsolete

There is a misconception that skived heat sink technology is outdated and has been replaced by newer technologies. However, skived heat sinks continue to be a popular choice due to their efficiency, versatility, and cost-effectiveness. Manufacturers are constantly innovating and improving skived heat sink designs to meet evolving industry demands.

Skived Heat Sinks Require Specialized Installation

Some believe that skived heat sinks require specialized installation and handling procedures, which may add to the overall costs. In reality, skived heat sinks can be easily installed in electronic devices using standard methods. Manufacturers provide clear guidelines for installing skived heat sinks to ensure optimal thermal performance.

Skived Heat Sink Technology is Not Environmentally Friendly

Finally, there is a misconception that skived heat sink technology is not environmentally friendly due to the materials used in their production. However, skived heat sinks can be manufactured using recyclable materials and sustainable practices. Additionally, the energy efficiency of skived heat sinks contributes to reducing overall environmental impact.