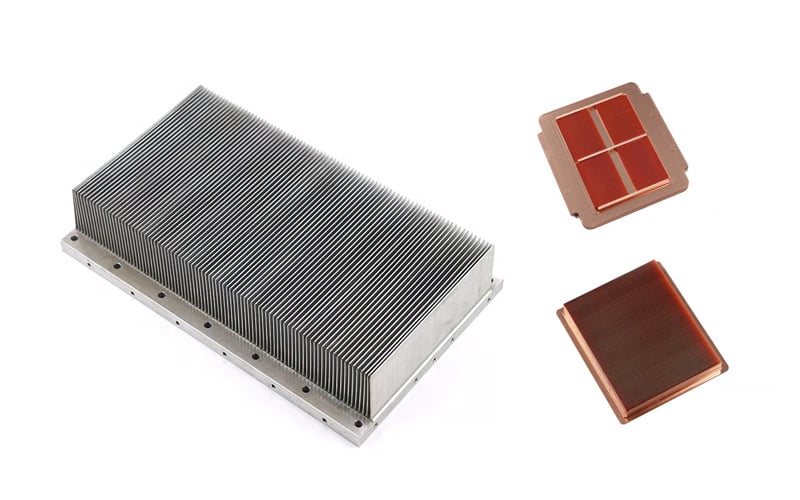

Introduction to Skived Heat Sinks

Skived heat sinks are a popular choice in the electronics industry due to their excellent thermal performance. These heat sinks are made by cutting thin metal sheets in a spiral pattern to increase surface area, allowing for efficient heat dissipation.

Cost-Efficiency of Skived Heat Sinks

One of the key advantages of skived heat sinks is their cost-efficiency. Compared to other types of heat sinks, such as extruded or bonded fins, skived heat sinks can be produced at a lower cost due to the manufacturing process involved.

Performance of Skived Heat Sinks

Despite their cost-saving benefits, skived heat sinks offer impressive thermal performance. The increased surface area created by the skiving process allows for better heat transfer, resulting in more efficient cooling of electronic components.

Durability and Longevity

Skived heat sinks are known for their durability and longevity. The sturdy construction of these heat sinks ensures that they can withstand high temperatures and frequent thermal cycling without degrading in performance.

Application Flexibility

Skived heat sinks are versatile in their application, making them suitable for a wide range of electronic devices. Whether used in computers, LED lighting, power supplies, or other electronics, skived heat sinks can adapt to different thermal requirements.

Installation Considerations

When evaluating the worth of skived heat sinks, it's essential to consider the ease of installation. Skived heat sinks are typically lightweight and easy to install, making them a convenient choice for manufacturers looking to streamline their assembly process.

Efficiency in Space-Constrained Designs

For products with limited space for cooling components, skived heat sinks offer a compact solution. Their efficient heat dissipation capabilities allow for effective cooling in tight spaces, maximizing the overall performance of the electronic device.

Comparative Analysis with Other Heat Sink Types

In a comparison of cost-efficiency and performance, skived heat sinks often outshine other types of heat sinks. While extruded heat sinks may offer similar thermal performance, skived heat sinks can be more cost-effective in large-scale production.

Industry Trends and Innovations

As technology continues to advance, manufacturers are constantly seeking ways to improve the cost-efficiency and performance of heat sinks. Skived heat sinks have remained a popular choice due to their balance of affordability and effectiveness in heat management.

Conclusion: Choosing the Best Heat Sink for Your Application

Ultimately, the decision to invest in skived heat sinks comes down to balancing cost-efficiency with performance requirements. By considering factors such as durability, thermal performance, and application flexibility, manufacturers can determine if skived heat sinks are worth the investment for their specific needs.