Efficient Cooling Solutions for Automotive Electronics

Skived heat sinks are becoming increasingly popular in the automotive industry as they offer efficient cooling solutions for a wide range of electronic components. These heat sinks are designed to dissipate heat effectively, ensuring that sensitive electronics stay within their optimal operating temperature range.

Compact Design for Space-Constrained Applications

One of the key advantages of skived heat sinks is their compact design, making them ideal for space-constrained automotive applications. With the rising demand for electronic components in vehicles, space optimization is crucial, and skived heat sinks offer a practical solution.

Enhanced Thermal Performance

Skived heat sinks are known for their superior thermal performance compared to traditional heat sink designs. The skiving process creates a larger surface area for heat dissipation, resulting in improved thermal efficiency and reliability for automotive electronics.

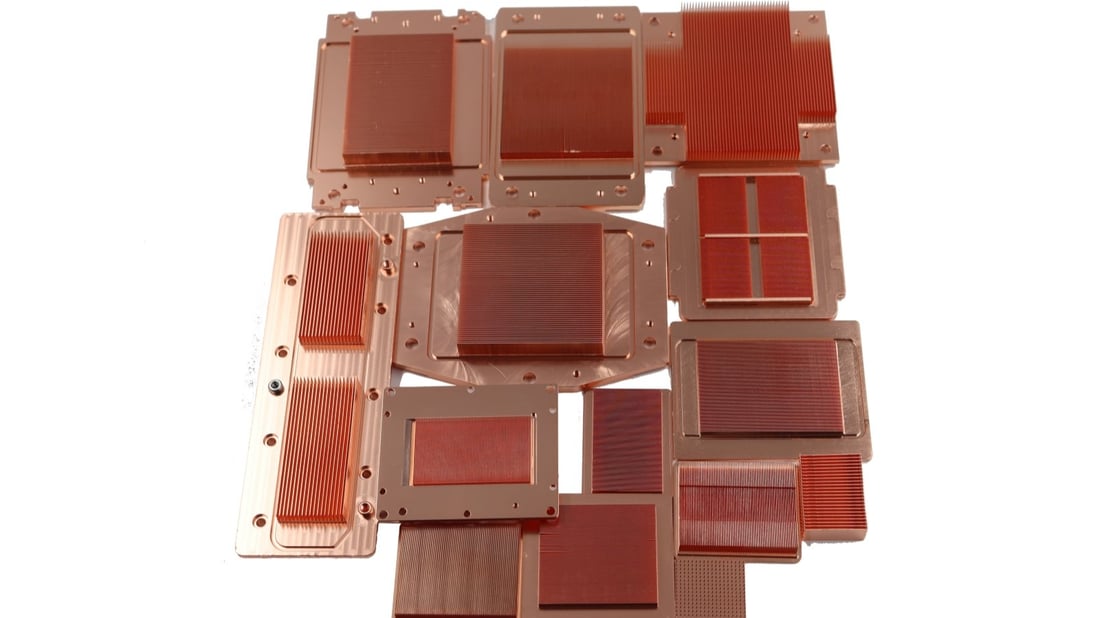

Customizable Solutions for Specific Requirements

Manufacturers can easily customize skived heat sinks to meet the specific requirements of automotive electronics. Whether it's a unique shape, size, or material composition, skived heat sinks can be tailored to optimize thermal management in various applications.

Cost-Effective Cooling Solutions

In addition to their superior performance, skived heat sinks also offer a cost-effective cooling solution for automotive electronics. The efficient manufacturing process of skived heat sinks allows for mass production at a lower cost, making them a practical choice for manufacturers.

Compatibility with Advanced Technologies

As automotive electronics continue to advance, the need for innovative cooling solutions also grows. Skived heat sinks are compatible with a wide range of advanced technologies, including electric vehicles, autonomous driving systems, and infotainment systems.

Reliability and Durability in Harsh Automotive Environments

Skived heat sinks are designed to withstand harsh automotive environments, providing reliable thermal management for electronic components exposed to extreme temperatures, vibrations, and contaminants. Their robust construction ensures long-term durability and performance.

Environmental Considerations in Automotive Design

With increasing focus on sustainability and energy efficiency in automotive design, skived heat sinks offer an environmentally friendly cooling solution. Their efficient heat dissipation helps reduce energy consumption and greenhouse gas emissions, aligning with eco-conscious automotive trends.

Collaboration with Automotive Industry Leaders

Skived heat sink manufacturers are partnering with automotive industry leaders to develop cutting-edge cooling solutions for next-generation vehicles. By working closely with OEMs and tier-1 suppliers, they ensure that skived heat sinks meet the evolving needs of the automotive electronics market.

Future Growth Opportunities in Automotive Electronics

As the automotive industry continues to embrace electrification and connectivity, the demand for efficient thermal management solutions like skived heat sinks is expected to grow. This trend presents exciting opportunities for innovation and collaboration in the fast-evolving field of automotive electronics.