Introduction to Thermal Resistance

Thermal resistance is a crucial factor to consider when it comes to heat sinks. It refers to the ability of a material to resist the flow of heat through it. In the case of skived heat sinks, understanding the factors that affect thermal resistance is essential for efficient heat dissipation.

Material Selection

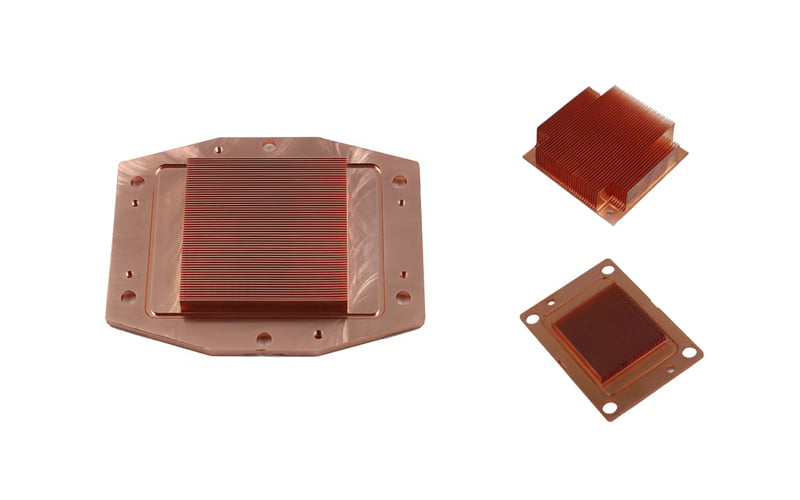

The material of the heat sink greatly impacts its thermal resistance. Common materials used for skived heat sinks include aluminum, copper, and their alloys. Each material has different thermal conductivity properties, which directly affect the overall thermal resistance of the heat sink.

Fin Design and Spacing

The design of the fins on a skived heat sink plays a crucial role in determining its thermal resistance. Factors such as fin height, thickness, and spacing between fins all impact the heat dissipation capabilities of the heat sink. A well-designed fin structure can significantly reduce thermal resistance.

Surface Finish

The surface finish of a skived heat sink can also affect its thermal resistance. A smooth surface finish allows for better contact between the heat sink and the heat source, improving heat transfer efficiency. Rough surfaces can lead to increased thermal resistance due to poor contact.

Mounting Method

The method used to mount the skived heat sink onto the heat source can impact thermal resistance. Proper mounting techniques ensure good contact between the two surfaces, reducing thermal resistance. Incorrect mounting can lead to air gaps, decreasing heat transfer efficiency.

Operating Environment

The operating environment of a skived heat sink can influence its thermal resistance. Factors such as ambient temperature, airflow, and surrounding components can impact the heat dissipation capabilities of the heat sink. Optimal operating conditions are essential for maintaining low thermal resistance.

Heat Source Characteristics

The characteristics of the heat source, such as size, power output, and thermal conductivity, can also affect the thermal resistance of a skived heat sink. Understanding the heat source properties is critical for selecting the appropriate heat sink design and materials.

Efficiency of Heat Transfer

The efficiency of heat transfer between the heat sink and the surrounding environment is a key factor in determining thermal resistance. Factors such as the presence of thermal interface materials, proper airflow, and effective heat dissipation mechanisms all play a role in minimizing thermal resistance.

Thermal Management Strategies

Implementing effective thermal management strategies is essential for reducing thermal resistance in skived heat sinks. This can include optimizing airflow, using thermal interface materials, and regularly maintaining the heat sink to ensure peak performance.

Conclusion

In conclusion, understanding the various factors that impact the thermal resistance of skived heat sinks is crucial for achieving efficient heat dissipation. By carefully considering material selection, fin design, surface finish, and operating conditions, it is possible to minimize thermal resistance and enhance overall performance.