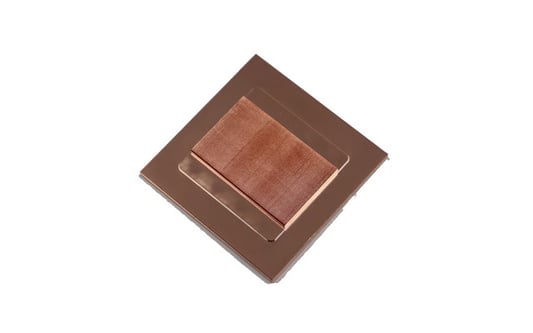

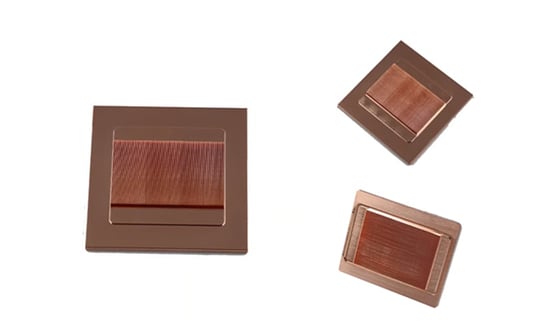

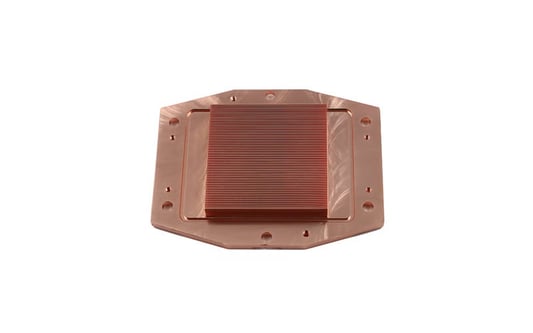

What are Skived Sinks?Skived sinks are a type of heat sink technology that allows for efficient heat dissipation in electronic devices. These sinks are created by skiving or cutting thin strips of metal from a solid block, resulting in a lightweight and highly effective cooling solution.The Benefits of Design FlexibilityOne of the key advantages of using skived sinks is their design flexibility. Manufacturers can create custom shapes and sizes to fit the specific requirements of each application. This versatility allows for efficient heat dissipation in a wide range of electronic devices, from small consumer electronics to large industrial equipment.Efficiency in Heat DissipationSkived sinks are designed to maximize surface area, allowing for greater heat dissipation. This efficient cooling solution helps to prevent overheating and ensures the optimal performance of electronic components. With skived sinks, manufacturers can design devices that operate at peak efficiency even under heavy workloads.Customization OptionsThe design flexibility of skived sinks extends to customization options such as different materials, finishes, and configurations. This allows manufacturers to tailor their heat sinks to meet the specific thermal requirements of their devices. Whether you need a compact sink for a mobile device or a larger sink for an industrial application, skived sinks offer the versatility needed to get the job done.Enhanced Thermal PerformanceBy optimizing the design of skived sinks, manufacturers can achieve enhanced thermal performance in their electronic devices. These sinks are engineered to efficiently dissipate heat and maintain lower operating temperatures, resulting in improved overall performance and longevity of the device.Cost-Effective SolutionDespite their advanced design capabilities, skived sinks offer a cost-effective solution for thermal management in electronic devices. The ability to customize the shape and size of the sink minimizes material waste and reduces production costs, making skived sinks a practical choice for manufacturers looking to optimize their budget.Applications in Various IndustriesSkived sinks are widely used in industries such as telecommunications, automotive, aerospace, and renewable energy. Their design flexibility makes them suitable for a diverse range of applications, from high-tech electronics to rugged outdoor equipment. Whatever the industry, skived sinks provide a reliable and efficient cooling solution.Environmental ConsiderationsIn addition to their functional benefits, skived sinks are also environmentally friendly. Their lightweight design requires less material and energy to produce, reducing carbon emissions and waste. As sustainability becomes a more significant concern for consumers and businesses, skived sinks offer a greener alternative for thermal management.Future Trends in Skived Sink TechnologyAs the demand for efficient cooling solutions continues to grow, skived sink technology is likely to evolve to meet new challenges. Advancements in materials science and manufacturing processes will enable even greater design flexibility and performance capabilities in skived sinks, making them an essential component in the next generation of electronic devices.ConclusionIn conclusion, Design flexibility skived sinks offer a versatile and efficient cooling solution for a wide range of electronic devices. Their customizable design, enhanced thermal performance, and cost-effective nature make them an attractive option for manufacturers looking to optimize the heat dissipation in their products. With ongoing technological advancements, skived sinks are set to remain a key player in the world of thermal management for years to come.Quote Inquirycontact us