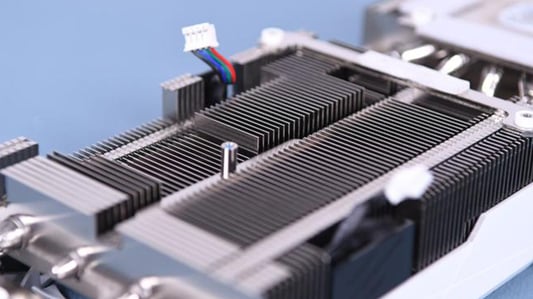

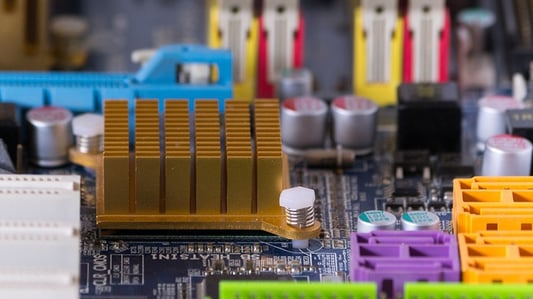

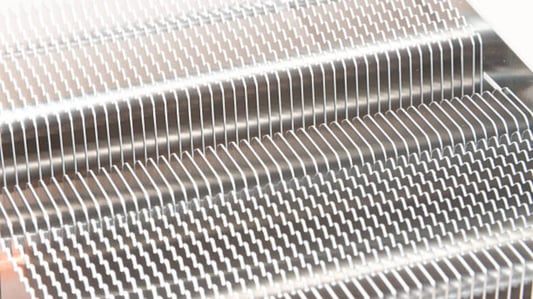

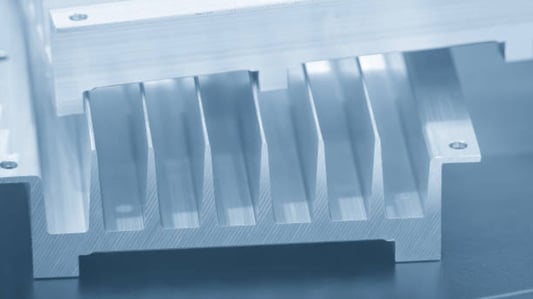

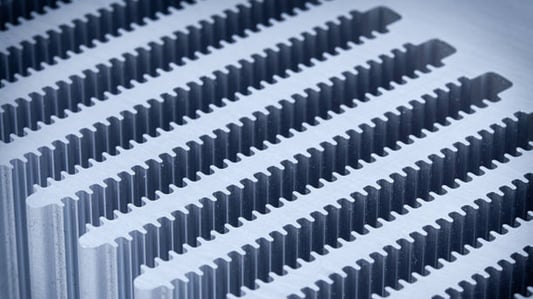

IntroductionWhen it comes to electronics, heat is one of the biggest enemies. As devices become smaller and more powerful, they generate a lot of heat that needs to be dissipated quickly. One solution to this problem is the use of a heat sink. In this article, we will explore the question of how many degrees per watt a heat sink can dissipate and what factors affect this value.What is a Heat Sink?Before we dive into the specifics of heat dissipation, let's first discuss what a heat sink is. A heat sink is a device that helps dissipate heat away from a hot component such as a processor or power amplifier. It is typically made of metal and consists of fins or other features that maximize surface area and allow for efficient heat transfer.Thermal ResistanceThe ability of a heat sink to dissipate heat is generally characterized by its thermal resistance. Thermal resistance is the temperature difference across the heat sink per unit of power dissipated. This value is typically given in units of degrees Celsius per watt (°C/W).Factors Affecting Thermal ResistanceThere are several factors that can affect the thermal resistance of a heat sink. One of the most important is the material that the heat sink is made of. Materials with high thermal conductivity such as copper and aluminum tend to have lower thermal resistances.Another factor that can affect thermal resistance is the size and shape of the heat sink. Heat sinks with larger surface areas and more fins tend to be more effective at dissipating heat than smaller ones.The airflow around the heat sink can also play an important role in its effectiveness. Heat sinks that are exposed to a strong and consistent airflow tend to perform better than those that are not.Calculating Thermal ResistanceThermal resistance can be calculated using the following formula:Thermal Resistance (°C/W) = (TJ - TA) / PWhere: TJ is the junction temperature of the component being cooled, TA is the ambient temperature of the surrounding environment, and P is the power dissipated by the component.Typical ValuesThe thermal resistance of a heat sink can vary widely depending on its design and construction. However, typical values for a well-designed heat sink range from 0.1°C/W to 1.0°C/W.ConclusionIn summary, the thermal resistance of a heat sink is an important factor in its effectiveness at dissipating heat from electronic components. Several factors such as material, size, shape, and airflow can affect its thermal resistance. Typical values for thermal resistance range from 0.1°C/W to 1.0°C/W.Top Factors Affecting Heat Dissipation Rate in Heat Sinks1. Material quality affects the heat dissipation rate of heat sinks.2. The size and shape of a heat sink play an important role in its effectiveness.3. The airflow around the heat sink can also affect its performance.4. The thermal interface material (TIM) between the heat source and the heat sink plays an important role in heat dissipation.5. Thermal conductivity of a heat sink is the rate at which heat travels through a material.6. The design of the fins on a heat sink affects its efficiency.7. The surface area of the heat sink also affects its performance.8. The stack-up of heat sinks plays an important role in their effectiveness.9. The number of heat pipes in a heat sink affects its thermal performance.10. The thickness of the base of a heat sink also affects its performance.