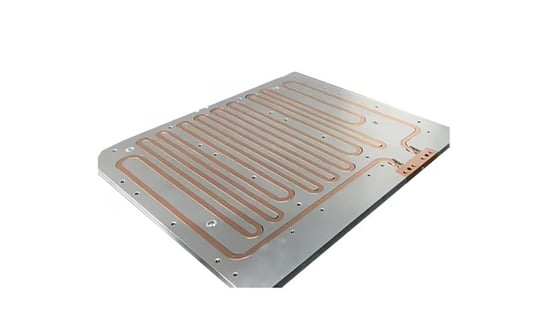

Introduction to Water Cooling Plates in Laser SystemsWater cooling plates have emerged as a revolutionary solution for maintaining optimal temperatures in laser systems. These plates, also known as cold plates, are essential components that help dissipate heat generated during the laser cutting process. How Water Cooling Plates WorkWater cooling plates work by circulating water through channels within the plate, absorbing heat from the laser system components. The heated water is then pumped out of the system and replaced with cooler water, allowing for continuous cooling of the system. This process helps prevent overheating and ensures consistent performance of the laser system.Advantages of Using Water Cooling PlatesThere are numerous advantages to using water cooling plates in laser systems. These plates are highly efficient at dissipating heat, resulting in improved performance and longevity of the system. Additionally, water cooling is a cost-effective and environmentally friendly cooling solution compared to other methods.Types of Water Cooling PlatesThere are various types of water cooling plates available for different laser system configurations. Some plates are designed for direct contact with the laser components, while others are integrated into the system's cooling loop. It is important to choose the right type of cooling plate based on the specific requirements of the laser system.Installation and Maintenance of Water Cooling PlatesProper installation and maintenance of water cooling plates are crucial for optimal performance of the laser system. It is recommended to follow manufacturer guidelines for installation and regularly check for any leaks or blockages in the cooling system. Routine maintenance will ensure efficient cooling and prevent potential damage to the system.Applications of Water Cooling Plates in Laser SystemsWater cooling plates are commonly used in a wide range of laser systems, including industrial cutting machines, medical devices, and scientific research equipment. These plates play a key role in maintaining stable temperatures and preventing thermal issues that can affect the performance of the laser system.Innovations in Water Cooling Plate TechnologyRecent advancements in water cooling plate technology have further improved the efficiency and reliability of laser systems. New materials and design innovations have led to enhanced thermal conductivity and heat dissipation capabilities, making water cooling plates an essential component in modern laser technology.Considerations for Choosing Water Cooling PlatesWhen selecting water cooling plates for a laser system, it is important to consider factors such as thermal resistance, flow rate, and compatibility with the system's components. Choosing the right cooling plate that meets the specific cooling requirements of the system will ensure optimal performance and longevity.The Future of Water Cooling Plates in Laser SystemsAs laser technology continues to advance, the demand for efficient cooling solutions like water cooling plates will only increase. Innovations in cooling plate design and materials will drive further improvements in the performance and reliability of laser systems, making water cooling a key component in the future of laser technology.ConclusionWater cooling plates have revolutionized the way laser systems are cooled, offering a reliable and cost-effective solution for dissipating heat and maintaining optimal temperatures. By understanding the benefits and applications of water cooling plates, laser system operators can ensure the performance and longevity of their systems for years to come.Quote InquiryContact us