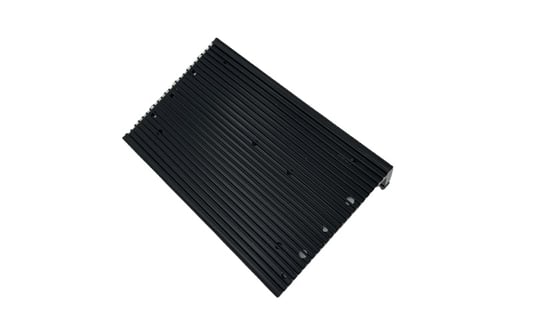

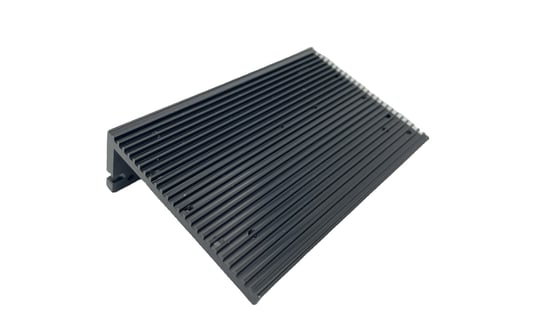

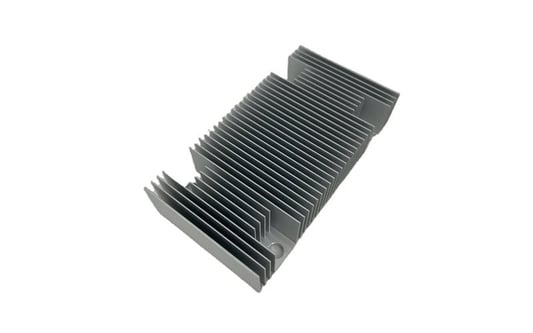

Efficient Coolingaluminum heat sink extrusions are widely used in various electronic devices to dissipate heat and maintain optimal operating temperatures. By providing a larger surface area for heat to be dissipated, these extrusions effectively cool down the components, extending their lifespan and improving overall performance.Lightweight and DurableOne of the key advantages of aluminum heat sink extrusions is their lightweight yet durable nature. Aluminum is a strong metal that can withstand harsh environments while being easy to handle and transport. This makes it an ideal choice for applications where weight is a concern.Customizable DesignsManufacturers can easily create custom designs for aluminum heat sink extrusions to meet specific requirements. Whether it's a unique shape, size, or surface finish, these extrusions can be tailored to fit the exact specifications of the device they are intended for.Cost-Effective SolutionCompared to other materials, aluminum heat sink extrusions offer a cost-effective cooling solution for electronic devices. Their affordability, coupled with their excellent thermal conductivity, makes them a popular choice among manufacturers looking to reduce production costs without compromising on quality.Thermal EfficiencyAluminum heat sink extrusions are designed to maximize thermal efficiency by efficiently transferring heat away from the components they are attached to. This prevents overheating and ensures consistent performance, even under heavy workloads or high temperatures.Easy InstallationInstalling aluminum heat sink extrusions is a straightforward process that requires minimal expertise. These extrusions can be easily mounted onto electronic devices using simple tools, allowing for quick and hassle-free assembly.Wide Range of ApplicationsFrom computer processors to LED lights, aluminum heat sink extrusions find applications in various industries where efficient cooling is essential. Their versatility and adaptability make them a suitable choice for different electronic devices and equipment.Corrosion ResistanceAluminum is naturally resistant to corrosion, making it an ideal material for heat sink extrusions that may be exposed to moisture or harsh chemicals. This resistance ensures the longevity of the extrusions, even in demanding environments.Environmentally FriendlyAluminum is a recyclable material that can be repurposed multiple times without losing its properties. This eco-friendly aspect makes aluminum heat sink extrusions a sustainable choice for manufacturers looking to reduce their environmental impact.Improved Device PerformanceBy effectively dissipating heat and maintaining optimal operating temperatures, aluminum heat sink extrusions contribute to improved device performance and reliability. This results in better overall user experience and satisfaction with the electronic products.Quote Inquirycontact usFactory