What are large heat sink extrusions?

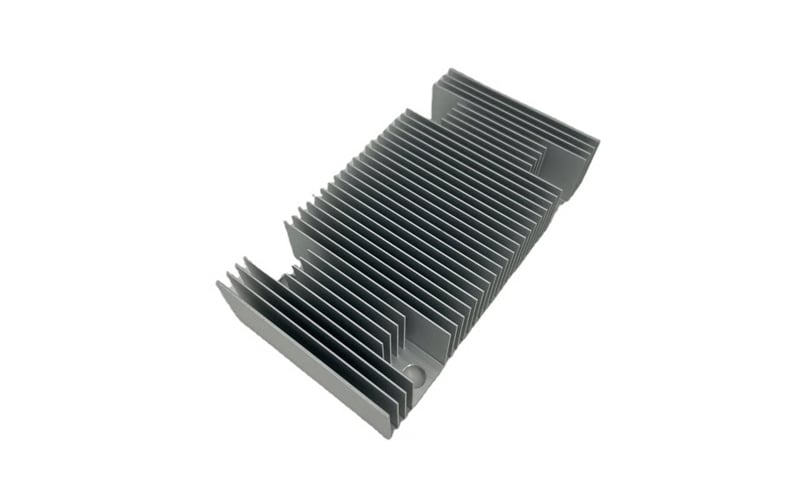

Large heat sink extrusions are essential components in thermal management systems. They are specially designed to dissipate heat generated by electronic devices to prevent overheating and ensure optimal performance. These extrusions come in various shapes and sizes to accommodate different applications and requirements.

The Function of Large Heat Sink Extrusions

The primary function of large heat sink extrusions is to efficiently transfer heat away from electronic components to the surrounding environment. By increasing the surface area exposed to air, heat sink extrusions help to dissipate heat more effectively, keeping the electronic devices at a safe operating temperature.

The Design of Large Heat Sink Extrusions

Large heat sink extrusions are typically made from aluminum or copper due to their high thermal conductivity. The design of these extrusions includes fins or ridges that increase the surface area available for heat dissipation. They can also be customized with different coatings or treatments to improve their performance.

Benefits of Using Large Heat Sink Extrusions

There are several benefits to using large heat sink extrusions in thermal management systems. These include improved efficiency in heat dissipation, extended lifespan of electronic devices, and enhanced overall performance. Large heat sink extrusions are also cost-effective solutions for preventing thermal issues.

Types of Large Heat Sink Extrusions

There are various types of large heat sink extrusions available on the market, including active and passive heat sinks. Passive heat sinks rely on natural convection to dissipate heat, while active heat sinks incorporate fans or other cooling mechanisms for enhanced thermal management. The choice of heat sink type depends on the specific application and thermal requirements.

Applications of Large Heat Sink Extrusions

Large heat sink extrusions are used in a wide range of industries and applications where thermal management is critical. They can be found in computer systems, LED lighting, power supplies, automotive electronics, and more. These extrusions play a crucial role in maintaining the optimal temperature of electronic devices.

Factors to Consider When Choosing Large Heat Sink Extrusions

When selecting large heat sink extrusions for a specific application, there are several factors to consider. These include the thermal conductivity of the material, the size and shape of the extrusion, the available space for installation, and the required thermal resistance. It is essential to choose the right heat sink to ensure efficient cooling.

Customization Options for Large Heat Sink Extrusions

Large heat sink extrusions can be customized to meet the unique requirements of different applications. Manufacturers offer a variety of customization options, including different shapes, sizes, finishes, and mounting configurations. Customized heat sink extrusions ensure optimal thermal performance in specific environments.

Installation and Maintenance of Large Heat Sink Extrusions

Proper installation and maintenance of large heat sink extrusions are essential to ensure their effectiveness in thermal management. It is important to follow manufacturer guidelines for installation and regularly clean the heat sink to remove dust and debris that can hinder heat dissipation. Routine maintenance helps prolong the lifespan of the heat sink.

Conclusion

In conclusion, large heat sink extrusions play a crucial role in thermal management systems by dissipating heat generated by electronic devices. These extrusions offer numerous benefits such as improved efficiency, extended device lifespan, and cost-effective thermal solutions. Understanding the different aspects of large heat sink extrusions is essential for selecting the right heat sink for specific applications.