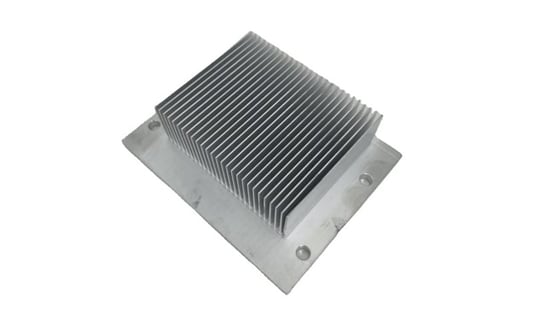

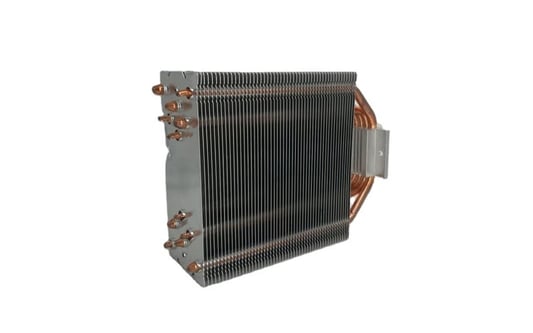

What are Heat Sink Module Solutions?Heat sink module solutions are crucial components in electronic devices that help dissipate excess heat, preventing overheating and potential damage. These modules are designed to efficiently transfer heat away from sensitive components, ensuring optimal performance and longevity.Why Are They Necessary?Without proper heat sink module solutions, electronic devices can overheat, leading to malfunctions, reduced lifespan, and even permanent damage. It is essential to invest in Cost-Effective Heat Sink Module Solutions to protect your devices and ensure optimal performance.The Importance of Cost-EffectivenessCost-effective heat sink module solutions provide high-quality performance at an affordable price point. By choosing the right solutions, you can effectively manage heat dissipation without breaking the bank.Types of Heat Sink Module SolutionsThere are various types of heat sink module solutions available, including passive heat sinks, active heat sinks, and liquid cooling systems. Each type offers unique benefits and features, making it essential to choose the right option for your specific needs.Benefits of Cost-Effective SolutionsCost-effective heat sink module solutions offer numerous benefits, including improved device performance, extended lifespan, energy efficiency, and cost savings. By investing in these solutions, you can protect your devices and maximize their functionality.Factors to ConsiderWhen choosing cost-effective heat sink module solutions, it is crucial to consider factors such as thermal conductivity, size, compatibility, and budget. By evaluating these factors carefully, you can select the right solution for your specific requirements.Installation and MaintenanceProper installation and maintenance of heat sink module solutions are essential to ensure optimal performance. Regular cleaning, monitoring, and maintenance can help prevent issues such as dust buildup, corrosion, and airflow obstructions.Future Trends in Heat Sink TechnologyAdvancements in heat sink technology are constantly evolving, with innovations such as graphene-based heat sinks, phase change materials, and miniature heat pipes. Staying informed about these trends can help you choose the most efficient and cost-effective solutions for your devices.Industry ApplicationsCost-effective heat sink module solutions are essential in a wide range of industries, including electronics, automotive, aerospace, and telecommunications. These solutions play a crucial role in maintaining device performance, reliability, and safety in various applications.Choosing the Right ProviderWhen sourcing cost-effective heat sink module solutions, it is essential to choose a reputable provider with a track record of delivering high-quality products. By selecting a trusted supplier, you can ensure that you are investing in reliable and efficient solutions for your devices.Quote Inquirycontact usFactory