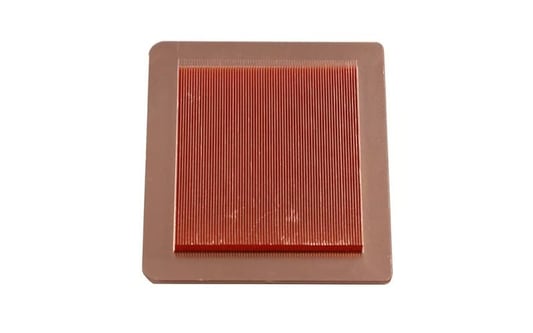

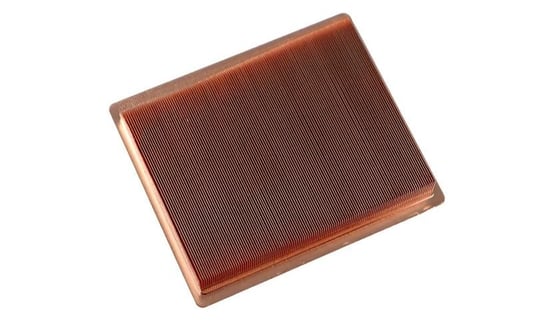

The Basics of a Finned Heat SinkA finned heat sink is a passive heat exchanger that helps to dissipate heat from electronic components by increasing the surface area for heat transfer. It is made up of a base plate and a series of fins that extend from the base plate, allowing for increased heat dissipation. These heat sinks are commonly used in electronic devices to prevent overheating and ensure optimal performance.How Do Finned Heat Sinks Work?Finned heat sinks work by transferring heat from the hot electronic components to the fins, which then dissipate the heat into the surrounding air. The increased surface area of the fins allows for more efficient heat transfer, ultimately cooling down the electronic device. This process is crucial for preventing thermal damage and ensuring the longevity of the electronic components.Types of Finned Heat SinksThere are various types of finned heat sinks available, including extruded, stamped, and bonded fin heat sinks. Extruded heat sinks are the most common type, manufactured by pushing aluminum through a die to create the desired shape. Stamped heat sinks are made by stamping sheets of metal, while bonded fin heat sinks have fins that are bonded to a base plate using epoxy or solder.Materials Used in Finned Heat SinksFinned heat sinks are typically made from aluminum or copper due to their excellent thermal conductivity properties. Aluminum is a cost-effective option and is lightweight, making it ideal for electronic devices. Copper, on the other hand, has even better thermal conductivity but is heavier and more expensive. The choice of material depends on the specific requirements of the application.Benefits of Using Finned Heat SinksFinned heat sinks offer several benefits, including improved thermal management, increased efficiency, and extended lifespan of electronic components. By effectively dissipating heat, finned heat sinks help prevent overheating and potential damage to sensitive electronic devices. They are also relatively easy to install and maintain, making them a popular choice for cooling solutions.Factors to Consider When Choosing a Finned Heat SinkWhen selecting a finned heat sink for a specific application, it is essential to consider factors such as thermal resistance, airflow, size, and mounting options. The thermal resistance of the heat sink determines its ability to dissipate heat, while airflow is crucial for efficient cooling. The size and mounting options should also match the requirements of the electronic device.Installation and Maintenance of Finned Heat SinksProper installation of a finned heat sink is essential to ensure effective heat dissipation. The heat sink should be securely attached to the electronic component using thermal interface materials to optimize heat transfer. Regular maintenance, such as cleaning the fins to remove dust and debris, is also important to maintain the heat sink's efficiency over time.Applications of Finned Heat SinksFinned heat sinks are widely used in electronic devices such as computers, laptops, LED lights, power supplies, and automotive electronics. They are also utilized in industrial applications, telecommunications equipment, and medical devices to manage heat generated by electronic components. Finned heat sinks play a critical role in maintaining the performance and reliability of these devices.Future Trends in Finned Heat Sink TechnologyAdvancements in finned heat sink technology are focused on improving thermal performance, reducing size and weight, and enhancing compatibility with new electronic components. Innovative designs, such as microchannel heat sinks and heat pipes, are being developed to address the evolving needs of high-performance electronics. The future of finned heat sinks looks promising with ongoing research and development efforts.ConclusionIn conclusion, a finned heat sink is a vital component in managing heat generated by electronic devices to prevent overheating and ensure optimal performance. By understanding how finned heat sinks work, the different types available, and the benefits they offer, you can make informed decisions when selecting a heat sink for your specific application. Proper installation, maintenance, and consideration of key factors will help maximize the efficiency and longevity of finned heat sinks.Quote InquiryContact us!