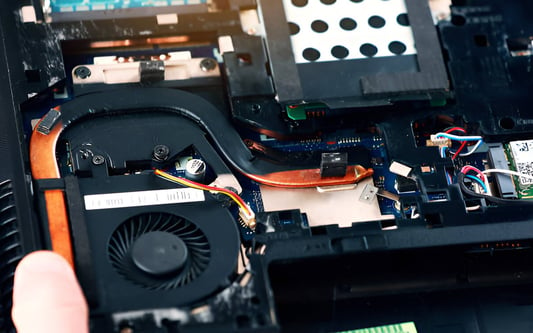

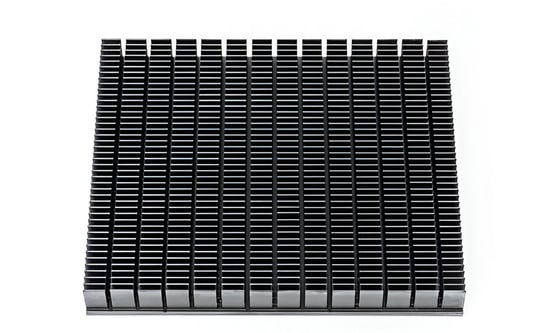

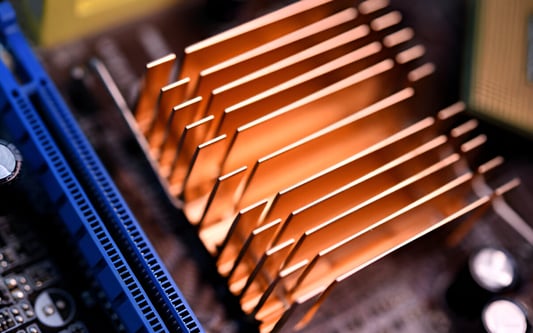

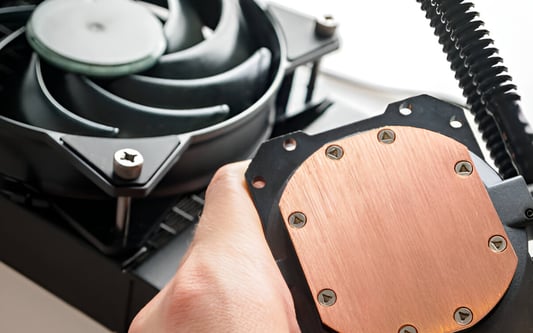

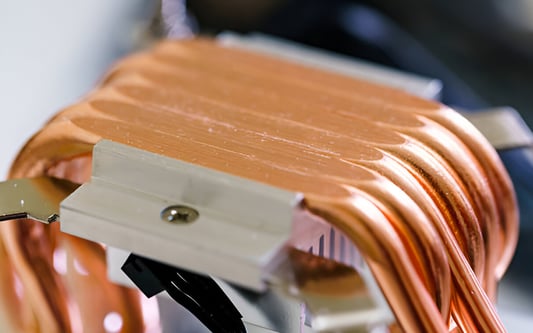

How to cool down a CPU without a cooler??When your computer is working hard, it's natural to notice your CPU getting hot. Overheating can damage internal components and lead to crashes. In this article, we will share some tips and tricks on how to cool down your CPU without a cooler.1. Clean the CPU heatsink and fanA dirty heatsink and fan can prevent proper cooling. Make sure that both are clean and free from dust and debris. Dust can accumulate over time and block the airflow, causing overheating issues. Use a soft-bristle brush or compressed air to clean it.2. Reapply thermal pasteThermal paste can dry out over time, leading to poor heat transfer. If your CPU is overheating, it may be time to replace or reapply thermal paste. When you apply thermal paste, make sure to spread it evenly and thinly over the surface of the CPU.3. Adjust power settingsIf your CPU is running at full speed all the time, it can generate more heat. In the power settings, you can choose the "balanced" option to reduce the workload on the CPU. This can help to lower the temperature of the CPU.4. Check the airflowProper airflow is essential for cooling your CPU. Make sure that the fans in your computer case are working correctly and positioned correctly, so they are pulling in cool air and expelling hot air. If necessary, add more fans to improve the airflow in your computer case.5. Use a laptop cooling padIf you're using a laptop, consider investing in a cooling pad. A cooling pad can provide extra cooling by circulating air underneath the laptop. It can also help to reduce the strain on the laptop's internal fan.6. Use a temperature monitoring programThere are many software programs that can monitor the temperature of your CPU. Use a temperature monitoring program to keep an eye on the CPU temperature. If the temperature starts to climb, you can take action to cool it down.7. Move the computer to a cooler locationIf your computer is in a warm or humid environment, it can lead to overheating. Move your computer to a cooler location with better air circulation. Avoid placing your computer near windows, direct sunlight, or heating vents.8. Undervolt your CPUUndervolting your CPU can help to reduce power consumption and heat output. This can be done in the BIOS settings or with software tools. You can lower the voltage of the CPU without affecting its performance.9. Use a liquid cooling systemIf your CPU is still running hot after trying all the above methods, consider using a liquid cooling system. Liquid cooling can be more effective than air cooling, but it can also be more expensive and complicated to install. It involves circulating coolant through a series of tubes and fins to absorb and dissipate heat.10. Upgrade the CPU coolerIf you are using a stock CPU cooler, consider upgrading it to a better one. Aftermarket coolers can provide better cooling performance compared to stock coolers. You can choose from air coolers or liquid coolers, depending on your needs and budget.Quote InquiryContact us