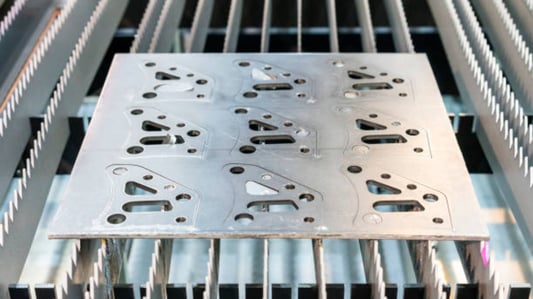

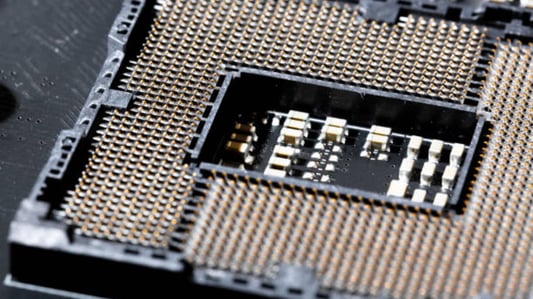

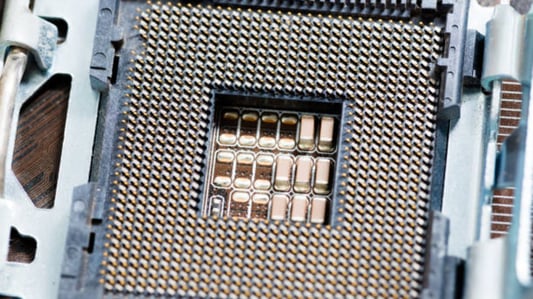

IntroductionIf you are in the electronics or computer industry, you know that heat sink is a critical component that helps dissipate heat from your devices. Aluminium is a popular material for heat sink manufacturing, and there are different grades of aluminium available. In this article, we will explore the question, "What grade aluminium is used for heat sink??" and provide you with all the information you need to know.6061 Aluminium6061 aluminium is a popular grade of aluminium that is commonly used for heat sinks. It has excellent thermal conductivity, high strength, good corrosion resistance, and is easily machinable. Additionally, it is readily available and cost-effective, making it a popular choice in various heat sink applications.7075 Aluminium7075 aluminium is a high-strength alloy commonly used in aerospace and high-performance applications. It has a higher tensile strength and is harder than 6061 aluminium, but its thermal conductivity is lower. However, engineers use 7075 aluminium for high-performance heat sink applications that require exceptional strength and durability.1100 Aluminium1100 aluminium is a pure aluminium grade that has excellent thermal conductivity and high electrical conductivity. It is ductile, malleable, and lightweight, making it an ideal material for heat sink applications that require good heat dissipation and electrical conductivity. However, it is relatively soft, and its mechanical properties are lower than other aluminium grades.3003 Aluminium3003 aluminium is another popular grade of aluminium used for heat sinks. It has excellent corrosion resistance, good thermal conductivity, and is easy to work with. It is often used for low-power applications since it does not have the same strength properties as 6061 or 7075 aluminium.Other Aluminium GradesThere are many other aluminium grades available that are used for heat sink manufacturing, depending on the specific application. For example, 5052 aluminium has good corrosion resistance and is often used in marine applications. 2024 aluminium is a high-strength alloy commonly used in aircraft applications. 5083 aluminium has excellent strength and is used in high-pressure applications. The choice of aluminium grade often depends on the application requirements, performance, and cost.Design ConsiderationsWhen designing a heat sink, there are several factors to consider, including size, shape, material, and thermal performance. The design should ensure maximum contact area for optimal heat transfer, adequate surface area for efficient cooling, and proper airflow to prevent heat buildup. The choice of aluminium grade should also consider factors such as the thermal conductivity of the material, its strength properties, and ease of fabrication.Manufacturing ProcessThe manufacturing process for heat sink typically involves several steps, including extrusion or casting to form the shape, CNC machining for finishing and secondary operations, and anodizing for protection against corrosion. The process varies depending on the material used and the size and complexity of the heat sink. It is crucial to select a manufacturing process that ensures high-quality heat sinks that meet all the application requirements.ConclusionAluminium is an excellent material for heat sink manufacturing due to its excellent thermal conductivity, strength, and durability. The choice of aluminium grade for a heat sink depends on various factors such as the specific application, performance requirements, and cost. However, 6061 aluminium is the most commonly used grade for heat sink applications due to its optimal combination of thermal conductivity, strength, and cost-effectiveness.Related Potential Long-Tail SEO KeywordsWhat is the best grade of aluminium for heat sinks?Thermal conductivity comparison of different aluminium grades for heat sinksAluminium grades comparison for heat sink applicationsHow to select the right aluminium grade for your heat sink?Quote InquiryContact us!