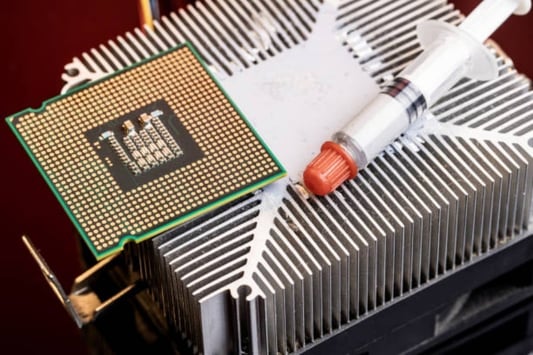

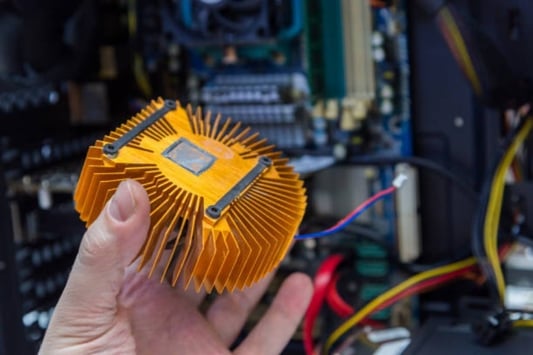

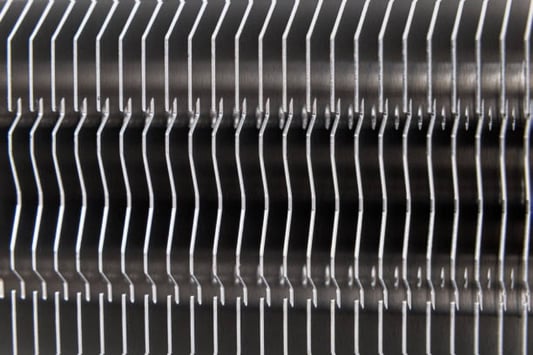

IntroductionWhen it comes to building a high-performance PC, one of the most important components to consider is the motherboard. And within the motherboard, the mosfet (metal–oxide–semiconductor field-effect transistor) heatsink is crucial for keeping your system running smoothly. In this article, we'll explain everything you need to know about motherboard mosfet heatsinks, including what they are, how they work, and how to choose the best one for your PC build.What is a Motherboard Mosfet Heatsink?A mosfet is a type of transistor that is used for power management in computers and other electronic devices. Mosfets generate heat when they switch on and off, and this heat needs to be dissipated in order to prevent damage to the components. That's where the mosfet heatsink comes in - it's designed to absorb and dissipate the heat generated by the mosfet, helping to keep the motherboard and other components cool.Why Do You Need a Motherboard Mosfet Heatsink?Without a mosfet heatsink, the mosfets on your motherboard can get extremely hot, which could lead to reduced performance and even damage to the components over time. A high-quality mosfet heatsink is essential for any PC builder who wants to ensure that their system operates at optimal levels over the long term.The Different Types of Motherboard Mosfet HeatsinksThere are several different types of mosfet heatsinks on the market, including passive heatsinks, active heatsinks, and water-cooled heatsinks. Passive heatsinks rely on natural convection to dissipate the heat, while active heatsinks use fans or other mechanisms to actively move air across the heatsink. Water-cooled heatsinks use liquid cooling to dissipate the heat, which can be more effective than air cooling in some cases.Considerations When Choosing a Mosfet HeatsinkWhen choosing a mosfet heatsink, there are several factors to consider. Firstly, you'll need to ensure that it's compatible with your motherboard. You'll also want to choose a heatsink that is appropriately sized for your system, and that has an effective heat dissipation rate. Finally, you'll want to consider the noise level of the heatsink, as some fans can be quite loud.Passive vs. Active Mosfet HeatsinksPassive mosfet heatsinks are the simplest and most affordable option, but they may not be sufficient for high-performance systems or for CPUs that generate a lot of heat. Active heatsinks, on the other hand, are more effective but are generally more expensive. They are also typically louder due to the fan or other components used to move air across the heatsink. Ultimately, the choice between passive and active heatsinks will depend on your specific needs and budget.The Benefits of Water-Cooled Mosfet HeatsinksWater-cooled mosfet heatsinks are the most effective option for dissipating heat, as water has a much higher heat capacity than air. They can also help to reduce noise levels compared to active heatsinks, as the heat is dissipated through a liquid rather than a fan. However, they are typically more expensive and require more maintenance than other types of heatsinks.How to Install a Mosfet HeatsinkThe installation process for a mosfet heatsink will depend on the specific model you choose, but in general, it will involve removing the existing heatsink (if applicable), cleaning the surface of the mosfet, applying thermal paste, and then attaching the new heatsink. Some heatsinks may also require additional mounting hardware or brackets.ConclusionA high-quality mosfet heatsink is an essential component for any PC builder who wants to ensure that their system runs smoothly over the long term. Whether you choose a passive, active, or water-cooled heatsink, be sure to consider factors such as compatibility, size, heat dissipation rate, and noise level when making your decision.Quote Inquiry