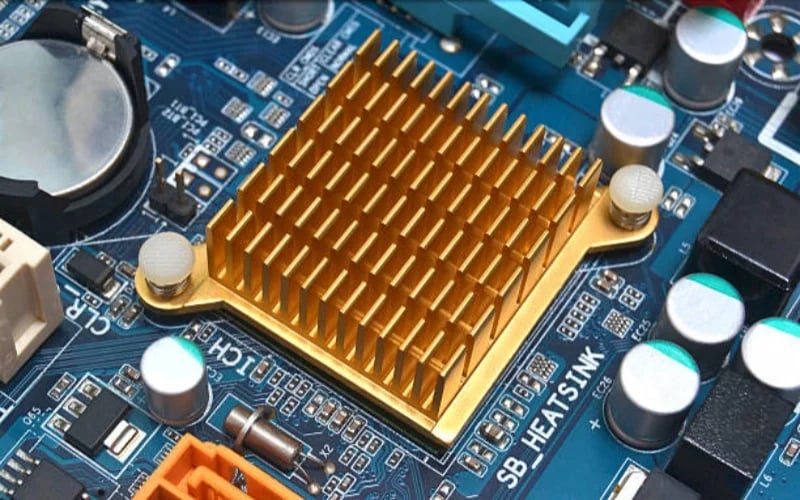

What is a Heat Sink?

A heat sink is an essential component of electronic devices that helps to dissipate heat generated by electronic components to keep the device from overheating. While various materials can be used in the construction of heat sinks, including copper, brass, and ceramics, aluminium stands out as the most cost-effective and efficient material due to its good thermal conductivity.

The Importance of large aluminium heat sinks

As the name suggests, large aluminium heat sinks provide an effective heat-dissipating solution for large electronic assemblies, such as power amplifiers, power supplies, and high-performance CPUs. They are typically custom-made to fit a particular electronic device and feature a large surface area, which facilitates the transfer of heat into the surrounding air by convection and radiation.

Types of Large Aluminium Heat Sinks

There are different types of large aluminium heat sinks available in the market, including extruded heat sinks, bonded fin heat sinks, folded fin heat sinks, and skived fin heat sinks. These options have varying thermal performance and are suitable for different applications, such as LEDs, electric vehicles, and telecom equipment.

The Advantages of Using Large Aluminium Heat Sinks

One of the primary advantages of using large aluminium heat sinks is their ability to dissipate heat efficiently, which helps to prolong the lifespan of the electronic device and prevent it from overheating. Additionally, aluminium is lightweight, corrosion-resistant, and easy to manufacture, making it a cost-effective and popular choice for heat sink applications.

Factors to Consider When Selecting Large Aluminium Heat Sinks

When choosing a large aluminium heat sink for your electronic device, you need to consider several factors, including the size, weight, and shape of the heat sink, the thermal resistance, and the air or fluid flow required to dissipate heat effectively. Additionally, you need to ensure that the heat sink is compatible with your device and can function optimally under different operating conditions.

Design Considerations for Large Aluminium Heat Sinks

Designing large aluminium heat sinks requires careful consideration to ensure optimal thermal performance. Some design considerations include increasing the surface area of the heat sink, improving the thermal conductivity of the material, and optimizing the fin design for better airflow. Additionally, the heat sink must be designed to handle the maximum heat dissipation requirements of the electronic device.

The Manufacturing Process of Large Aluminium Heat Sinks

The manufacturing process of large aluminium heat sinks varies depending on the type of heat sink being produced. Extruded heat sinks, for instance, are made by forcing heated aluminium through a shaped die to create the desired profile. Skived fin heat sinks, on the other hand, are made by slicing thin fins from a solid block of aluminium using a specially designed skiving machine. Regardless of the manufacturing method used, large aluminium heat sinks must undergo stringent quality checks to ensure they meet the required specifications and performance standards.

The Cost of Large Aluminium Heat Sinks

The cost of large aluminium heat sinks varies depending on several factors, such as the size, complexity of the design, and the quantity required. Generally, larger heat sinks with intricate designs are more expensive to manufacture. However, large aluminium heat sinks are a cost-effective solution for dissipating heat compared to other materials, such as copper and ceramics.

The Future of Large Aluminium Heat Sinks

The demand for large aluminium heat sinks is expected to grow in the future due to the increasing need for efficient heat dissipation in power electronics, automotive applications, and data centers. Moreover, advancements in manufacturing technologies, such as additive manufacturing, will likely lead to the development of new heat sink designs that offer better thermal performance and cost-effectiveness.

Conclusion

Large aluminium heat sinks are critical components of electronic devices, playing a significant role in dissipating heat and prolonging the lifespan of the device. They are lightweight, cost-effective, and easy to manufacture, making them an ideal solution for large electronic assemblies. To ensure optimal performance, it is essential to consider factors such as thermal resistance, size and shape, and compatibility when selecting and designing large aluminium heat sinks.