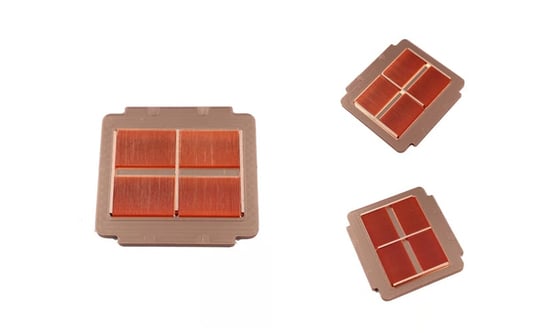

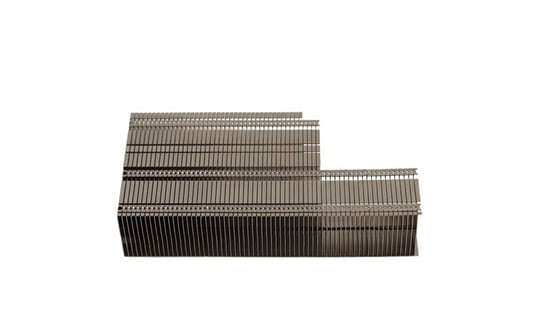

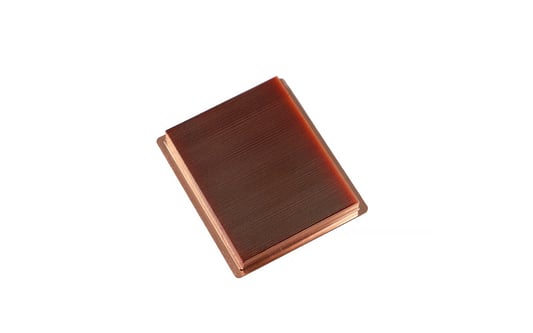

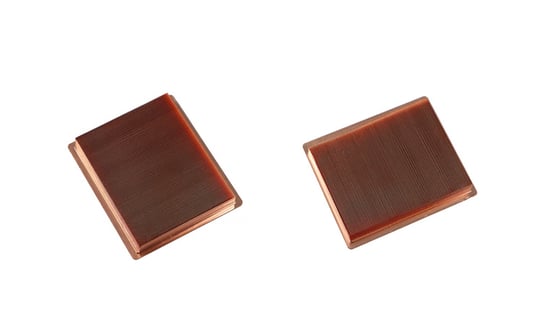

Importance of Compact high-performance coolingCompact high-performance cooling systems play a crucial role in various industries where maintaining the optimal temperature is essential. These systems are designed to efficiently remove heat from electronic components, machinery, or processes, ensuring they operate at peak performance levels.Advanced Technology in Compact Cooling SystemsThe latest advancements in technology have allowed for the development of highly efficient compact cooling systems. These systems utilize state-of-the-art materials and innovative designs to provide superior cooling capabilities in a compact form factor.Energy Efficiency and SustainabilityCompact high-performance cooling systems are engineered to be energy-efficient, helping reduce overall energy consumption and operating costs. By cooling effectively while using minimal energy, these systems contribute to sustainable practices in various industries.Space-Saving SolutionsOne of the key benefits of compact high-performance cooling systems is their space-saving design. These systems are ideal for applications where space is limited, offering a compact and efficient cooling solution without compromising performance.Enhanced Cooling PerformanceCompact high-performance cooling systems are specifically designed to provide superior cooling performance even in challenging environments. With advanced cooling technologies and optimized airflow, these systems can effectively dissipate heat and maintain optimal temperatures.Applications in Electronics CoolingCompact high-performance cooling systems are widely used in electronics cooling applications, where maintaining the right temperature is crucial for the functionality and longevity of electronic components. These systems are designed to efficiently cool electronic devices and prevent overheating.Industrial Cooling SolutionsIn industrial settings, compact high-performance cooling systems are essential for maintaining operational efficiency and preventing equipment failures due to overheating. These systems are integral in keeping machinery and processes running smoothly.Automotive Cooling InnovationsThe automotive industry relies on compact high-performance cooling systems to regulate engine temperatures and prevent overheating. These systems play a vital role in ensuring the performance and reliability of vehicles, especially in high-performance and racing applications.Customization Options for Specific NeedsManufacturers of compact high-performance cooling systems offer customization options to meet specific requirements of different industries. Whether it's for size constraints, performance demands, or environmental factors, these systems can be tailored to suit various applications.Future Trends in Compact CoolingAs technology continues to advance, we can expect to see further innovations in compact high-performance cooling systems. Future trends may include even more energy-efficient designs, enhanced cooling capacities, and integration with smart technology for monitoring and control.Quote Inquirycontact us